Operate as a Cut Center

The Thermwood Cut Ready Cut Center is an alternative to traditional CNC routers for making a wide variety of products including cabinets, closets, furniture, doors, drawers and more. Just tell the machine what you what to make and it does it...it is that simple! NO programming is required.

The Thermwood Cut Ready Cut Center is an alternative to traditional CNC routers for making a wide variety of products including cabinets, closets, furniture, doors, drawers and more. Just tell the machine what you what to make and it does it...it is that simple! NO programming is required.

Operate as a CNC Router

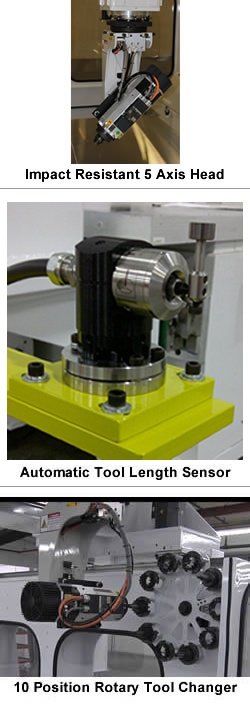

Also, you can operate the system as a CNC router in the traditional manner, running programs generated with virtually any CNC software. Thermwood has created a simple way to switch between operating as a CNC router and operating as a Cut Center to assure that all machine parameters are properly reset and that the standard Cut Center tooling is properly installed, checked and ready to run.

What our Customers Say...

Other CNC Routers - Programming Required?

Every CNC router, regardless of price, has one thing in common..it must be programmed. You will need a CNC programmer. A typical CNC programmer will cost you more each month than the payment on a Thermwood Cut Center, which does not need CNC programs or CNC programmers.

So, even if a machine was FREE, it would still cost you more than a Thermwood Cut Center, and in a few years the Cut Center payments go away while your programmer costs most likely will go up.

Get Into Production Quickly

Also, it is likely you will be in full production with a Thermwood Cut Center in about a half a day. A CNC router can take as much as six months to program and get to that point. A half a day or a half a year? There is serious cost associated with that half a year.

Also, it is likely you will be in full production with a Thermwood Cut Center in about a half a day. A CNC router can take as much as six months to program and get to that point. A half a day or a half a year? There is serious cost associated with that half a year.

Not So Cheap After All

When you consider everything, a cheap router isn’t so cheap after all. In fact, to match a Thermwood Cut Center THEY would have to pay YOU to use their router.

Instead of looking for the cheapest possible CNC router, do this thing right, get a Thermwood Cut Center….your life will be better and you will make more money.

The Bottom Line...

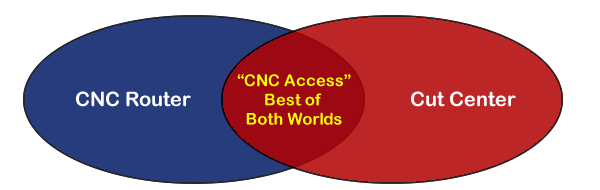

Don't have extensive programming experience? Have programming experience and want both the flexibility of a CNC router and the ease of use of a Cut Center? Looking for a machine that will grow with your business? Then Thermwood's Cut Ready Cut Center with new "CNC Access" is the machine for you!

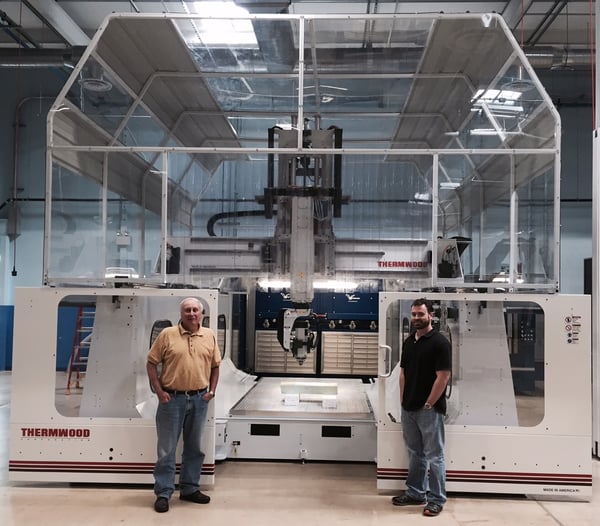

(Back row), Troy, Jody Wilmes of Thermwood, Kenny and Michael (front row) of Bednark Studio in Brooklyn, NY with their new Thermwood Cut Ready Cut Center at their shop.

Cody, John, Christina and Alberto of Arkansas Wood Doors in Pottsville, AR with their new Thermwood CutReady Cut Center at their shop.

Donovan Mumma of Byrne Custom Woodworking in Lenexa, KS with Jody Wilmes of Thermwood and their new Thermwood CutReady Cut Center at their shop.

Every CNC router, regardless of price, has one thing in common..it must be programmed. You will need a CNC programmer. A typical CNC programmer will cost you more each month than the payment on a Thermwood Cut Center, which does not need CNC programs or CNC programmers.

Every CNC router, regardless of price, has one thing in common..it must be programmed. You will need a CNC programmer. A typical CNC programmer will cost you more each month than the payment on a Thermwood Cut Center, which does not need CNC programs or CNC programmers.

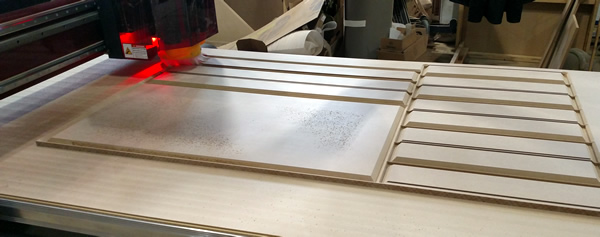

The AutoProcessor 5'x10' is a high-speed, automatic load/unload, heavy-duty CNC routing system for nested based feed through machining. It is used in nested based production of cabinets, closets and custom furniture.

The AutoProcessor 5'x10' is a high-speed, automatic load/unload, heavy-duty CNC routing system for nested based feed through machining. It is used in nested based production of cabinets, closets and custom furniture.