More LSAM Videos

Why LSAM?

Companies have been choosing Thermwood's LSAM large scale additive manufacturing systems for their thermoplastic composite large part production. Scott Vaal, Thermwood’s LSAM Product Manager, addresses the question of “Why LSAM?”

Introducing the Thermwood Additive Printer

In response to requests for a somewhat smaller, lower cost additive system which still has all the features and print quality of the large flagship LSAM systems, Thermwood has developed and is now offering a line of “print only” machines.

Al Davis Memorial Torch at Allegiant Stadium in Las Vegas

LSAM owner Dimensional Innovations developed and built the 93-foot tall, 3D-printed commemorative Al Davis Memorial Torch in the new Las Vegas Raiders stadium using their Thermwood LSAM 1020 Large Scale Additive Manufacturing System!

Take a Tour of the Thermwood LSAM

LSAM (Large Scale Additive Manufacturing) Product Manager, Scott Vaal explains all the different aspects of the Thermwood LSAM and provides insight into this unique solution for large scale additive manufacturing.

LSAM 1020 printing a Multi-Piece Foundry Pattern

The pattern was printed on an LSAM 1020, and machined on a Thermwood 5 Axis Model 90 (because of other projects that were pending on the LSAM).

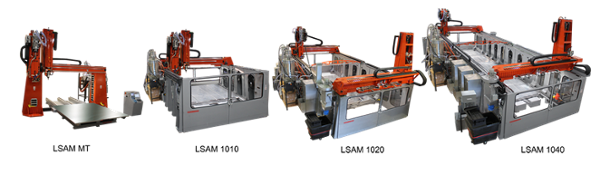

Introducing the LSAM MT

The LSAM MT, offers an all new configuration and significant advantages in certain applications. It features a single fixed gantry mounted over a moving table. Available with a 10x10 foot table.

LSAM MT High Temp Demonstration

Watch the LSAM MT VLP (Vertical Layer Print) a high temperature part out of Techmer PM 25% carbon fiber filled PSU/PESU blend.

Thermwood and Bell 3D Print Helicopter Blade Mold

A joint venture program between Thermwood and Bell has pushed the limits of 3D printing, resulting in what Thermwood believes is the largest 3D printed autoclave capable tool ever made. This mold, for an 18 1/2 foot long helicopter blade, and is comprised of two halves, which fit together to form the blade.

Unclassified Submarine Nose 3D Printed for US Navy

This initial validation program was centered on printing an unclassified scale nose of a submarine using Thermwood’s LSAM additive manufacturing system.

Boeing and Thermwood partner to create large, single-piece tool for the 777X program

Boeing and Thermwood Corporation have employed additive manufacturing technology to produce a large, single-piece tool for the 777X program. The project is demonstrating that additive manufacturing is ready to produce production quality tooling for the aerospace industry.

LSAM 3D Printed Marine Boat Hull Pattern

3D Printed Marine Boat Hull Pattern made out of Techmer Electrafil© ABS LT1 3DP. The entire print, assembly and trim process required less than ten working days to complete.