ISA 2011 – What we learned

We just returned from the International Sign Expo in Las Vegas, and had a great time. It was enjoyable meeting new people in this expanding industry. We got a lot of interesting feedback from companies in the industry about their need to constantly evolve and expand what they offer to meet the growing needs of their customers.

We just returned from the International Sign Expo in Las Vegas, and had a great time. It was enjoyable meeting new people in this expanding industry. We got a lot of interesting feedback from companies in the industry about their need to constantly evolve and expand what they offer to meet the growing needs of their customers.

From vehicle wraps to window graphics and three dimensional signs, today’s sign professionals have to be able to offer at least as much, and usually a whole lot more than their competitors to survive and thrive. They have to be able to think outside the box to grab any piece of business that comes their way, and traditional sign trimming machines only meet some of these needs.

We have learned that these traditional machines are comparatively light-duty when it comes to any type of heavier material or non-traditional application. Or, if they can machine the necessary material, it is oftentimes very unproductive (requiring multiple passes and valuable time). This can cause you to miss out on jobs that your equipment simply can’t do.

What now?

You’ve seen this in other industries. There reaches a point when everybody’s product basically does the job. Some do it better than others, but they all get the job done. After that, the market is saturated with copy-cats until someone comes up with a new innovation or way to use the technology in a different way. Just like cell phones gave way to smart phones and laptops are slowly going away in favor of tablets, there is a new solution to the problems facing the sign industry.

You’ve seen this in other industries. There reaches a point when everybody’s product basically does the job. Some do it better than others, but they all get the job done. After that, the market is saturated with copy-cats until someone comes up with a new innovation or way to use the technology in a different way. Just like cell phones gave way to smart phones and laptops are slowly going away in favor of tablets, there is a new solution to the problems facing the sign industry.

A different approach

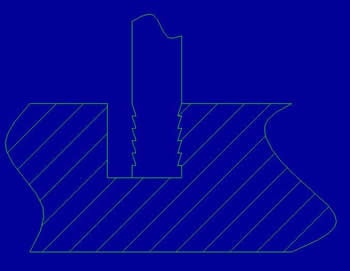

Using a heavy-duty sign machine like the Thermwood SignRouter 43 offers the ability to cut and trim printed graphic signs on rigid substrates as well as machining and carving three dimensional signs and letters (all much faster than traditional machines). In addition to those features, it can also operate as a high-production CNC Router, giving owners the advantage of being able to offer a whole additional variety of products to their customers.

The SignRouter43 is capable of machining flat and three-dimensional signs using wood, aluminum, composites, chip core, rigid foam, plastics, acrylic, non-ferrous metals and other various types of materials as well as operating as a traditional sign-making machine using optional i-cut Vision camera and software (these highly capable systems accurately trim printed signs, automatically compensating for distortion or rotation in the printed image).

The SignRouter43 is capable of machining flat and three-dimensional signs using wood, aluminum, composites, chip core, rigid foam, plastics, acrylic, non-ferrous metals and other various types of materials as well as operating as a traditional sign-making machine using optional i-cut Vision camera and software (these highly capable systems accurately trim printed signs, automatically compensating for distortion or rotation in the printed image).

At the show, we demonstrated the SignRouter 43 with a 5’×10 fixed table, featuring a 12 HP HSD spindle and an eleven position automatic tool changer. It features both high acceleration and high performance motions in both positioning and cutting. This system includes quality features seldom, if ever, found at this price point including full stress relieved weldments, high-end Siemens drives throughout, THK rails and three-dimensional volumetric position compensation. In addition to the 5’×10 table, we also offer a larger variety of table sizes (dual or moving tables/vacuum hold-down methods available).

Thinking outside the box

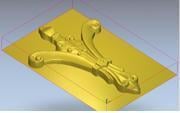

A unique aspect of our technology is the ability to do a lot more than just signs.

A unique aspect of our technology is the ability to do a lot more than just signs.

Thermwood’s SignRouter43 with “QuickCut” technology also offers a revolutionary new approach for nested based applications. Just select and resize cabinets, closet components and POP displays, then make them…right at the machine. You don’t need design software. You don’t need extensive training or a painful learning curve. Pretty much anyone in your shop can make cabinets and closets with a few minutes instruction. It’s not much more difficult than running a copy machine.

This can allow you to greatly expand your product offering with the same machine you use to produce your traditional signs!