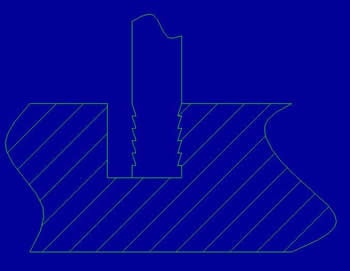

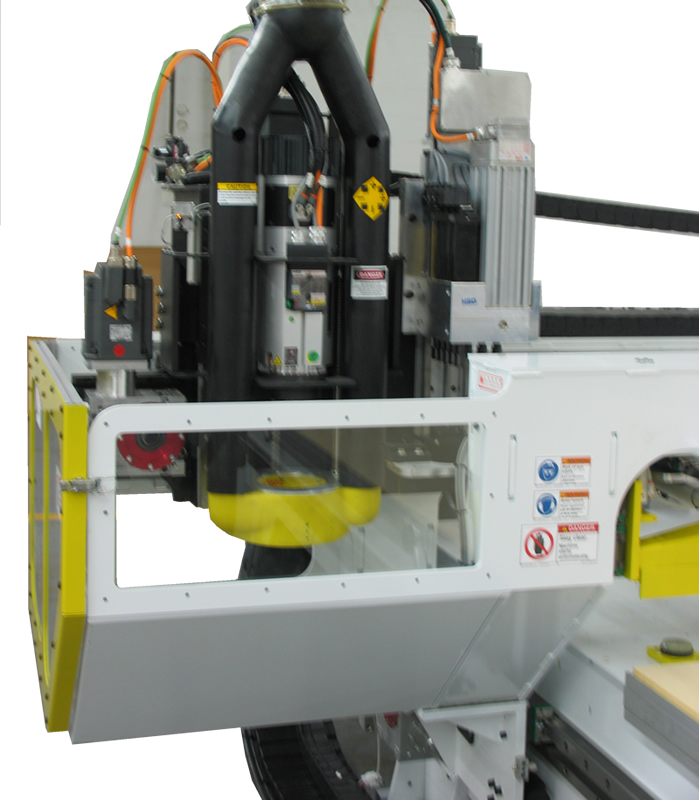

Thermwood's latest machine, the AutoProcessor 5x10 - Shown at the 2012 IWF show in Atlanta, GA Booth #5753.

The AutoProcessor 5×10 is a complete solution for Nested Based Panel Processing, Cabinet/Closets, Marine/Boat Building, Furniture Manufacturing, Exhibits/ Store Fixtures, Machining Plastic Sheets and High Volume Cabinet Production.

With each cycle, the machine first labels the sheet, positions the sheet on the table, machines the material, off-loads the finished parts and then repeats the process. Dust collection during this process keeps scrap and debris to a minimum. Labels help the operator to quickly sort the parts, and Assembly Marks help final assembly happen quickly and easily.

Features:

Features:

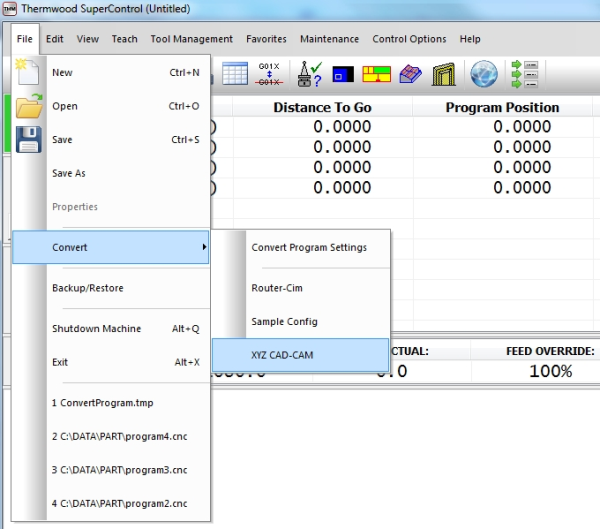

• Thermwood QCore SuperControl

•5’ x 10’ Working Table / Moving Gantry

• Rapid Speed 4,200 IPM

• 4000 lb. Lift Table for Loading

• 12 HP HSK Electro-Spindle

• 8 Position Tool Changer

• Automatic Pop-Up Pins

• Automatic Tool Sensor

• Automatic CNC Labeler

• 9 Spindle Drill Bank

• Unload Table

More information can be found here

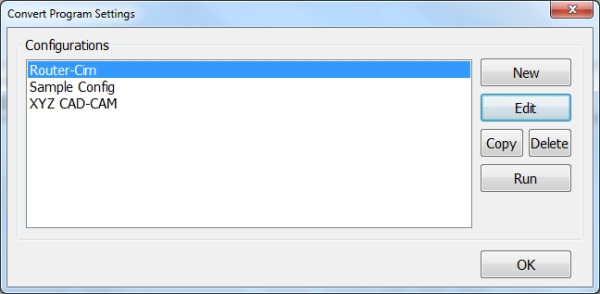

Training at Thermwood is conducted in a modern, comfortable and well equipped center devoted specifically to educating our customers. This is, by far, the fastest and most efficient way to learn. Over the years, Thermwood has experienced the ups and downs of training at the customer's facility, the interruptions and distractions, not to mention the lack of classroom facilities and equipment. It just doesn’t work very well. At Thermwood, the atmosphere contributes to the learning experience. Each classroom is setup specifically for the course being taught.

Training at Thermwood is conducted in a modern, comfortable and well equipped center devoted specifically to educating our customers. This is, by far, the fastest and most efficient way to learn. Over the years, Thermwood has experienced the ups and downs of training at the customer's facility, the interruptions and distractions, not to mention the lack of classroom facilities and equipment. It just doesn’t work very well. At Thermwood, the atmosphere contributes to the learning experience. Each classroom is setup specifically for the course being taught. Our machine operator/programmer courses are located adjacent to the machine training lab, where students complete the prescribed projects on a specific training machine utilized only for training purposes. Our application software classes are conducted in a classroom with state-of-art computer equipment. Then when it comes time for practical applications on a full sized machine, Thermwood's training lab is equipped with a

Our machine operator/programmer courses are located adjacent to the machine training lab, where students complete the prescribed projects on a specific training machine utilized only for training purposes. Our application software classes are conducted in a classroom with state-of-art computer equipment. Then when it comes time for practical applications on a full sized machine, Thermwood's training lab is equipped with a  Thermwood also has a customer lounge and workstation available for use during your training at our facility. This comfortable area features free:

Thermwood also has a customer lounge and workstation available for use during your training at our facility. This comfortable area features free: Our five-day machine programming/operations training here at Thermwood is the first step to helping you hit the ground running. The goal is to help you understand how to utilize the power of your Thermwood CNC Router and

Our five-day machine programming/operations training here at Thermwood is the first step to helping you hit the ground running. The goal is to help you understand how to utilize the power of your Thermwood CNC Router and