Cut Ready - The First CNC That Doesn't Need a Programmer!

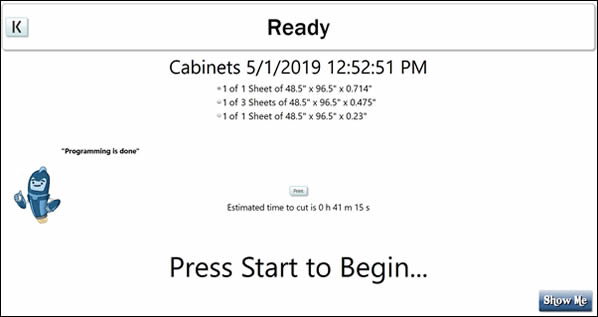

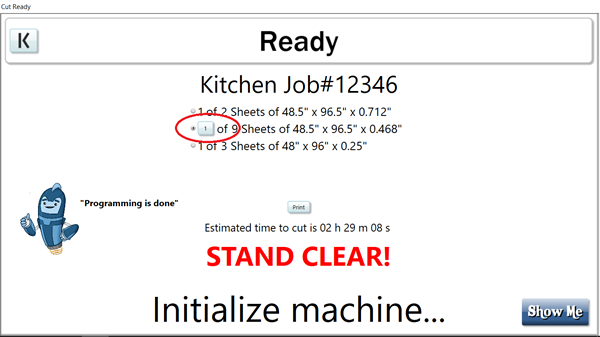

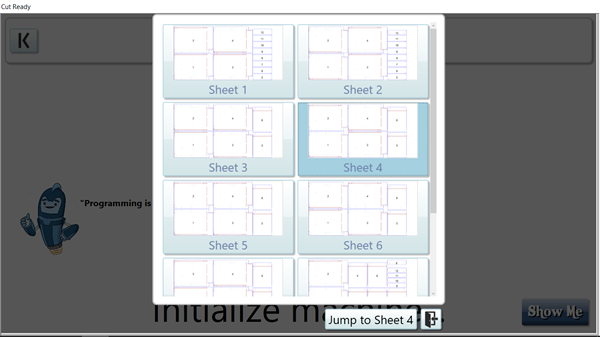

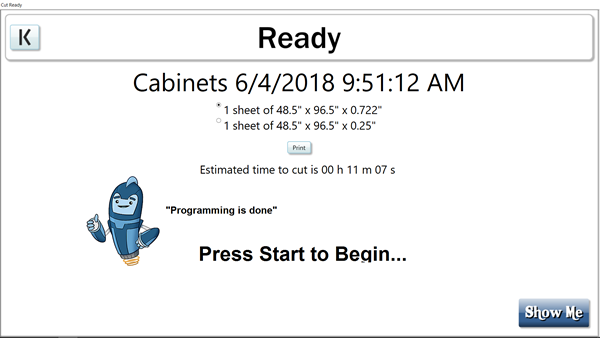

Cut Ready doesn’t need a programmer because there is already one inside the control. We call him “Artie”.

Cut Ready doesn’t need a programmer because there is already one inside the control. We call him “Artie”.

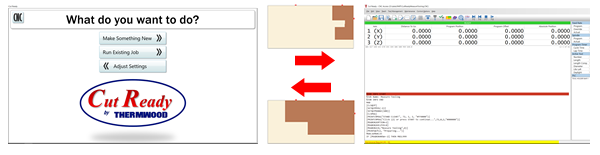

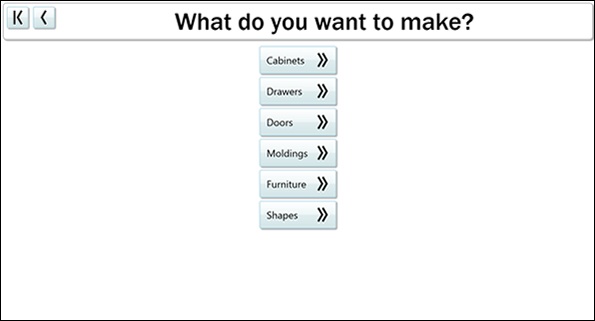

Despite the cute name, Artie is actually a cutting edge, artificial intelligence engine inside the Cut Ready control. You tell him what you want and he creates a program to make it.

Artie has actually been hiding out behind the scenes in the Cut Ready control this whole time, but he has never made an appearance until now. He is the first A.I. dedicated to making your manufacturing life easier to handle. While he is a CNC programmer and designer at heart, he also watches over your shoulder to make sure everything goes smoothly and efficiently.

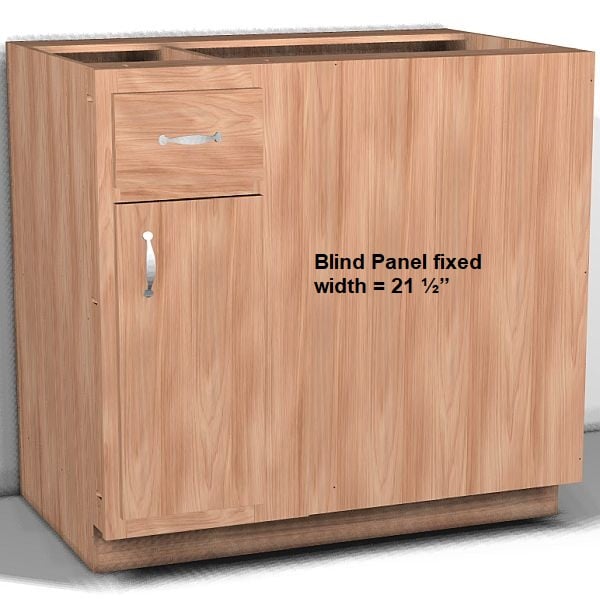

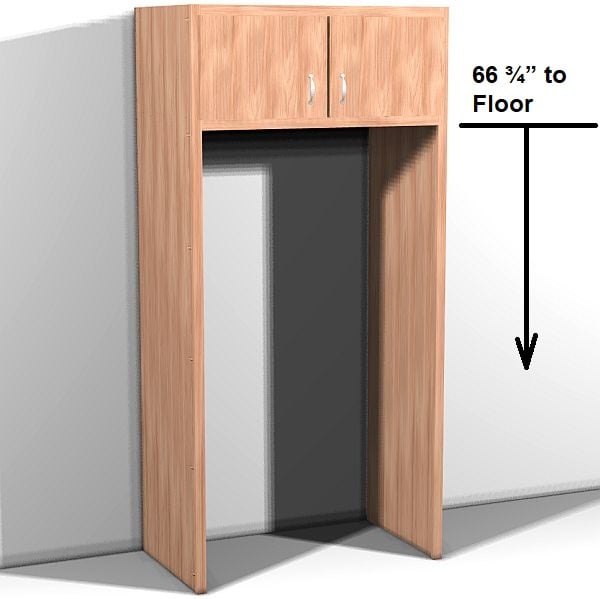

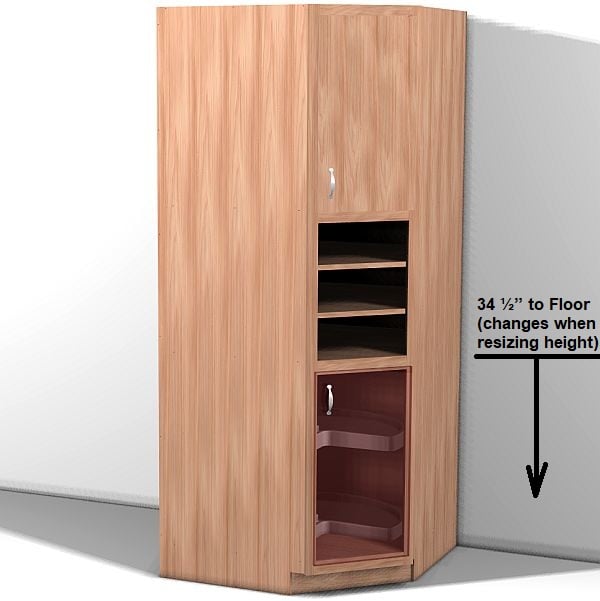

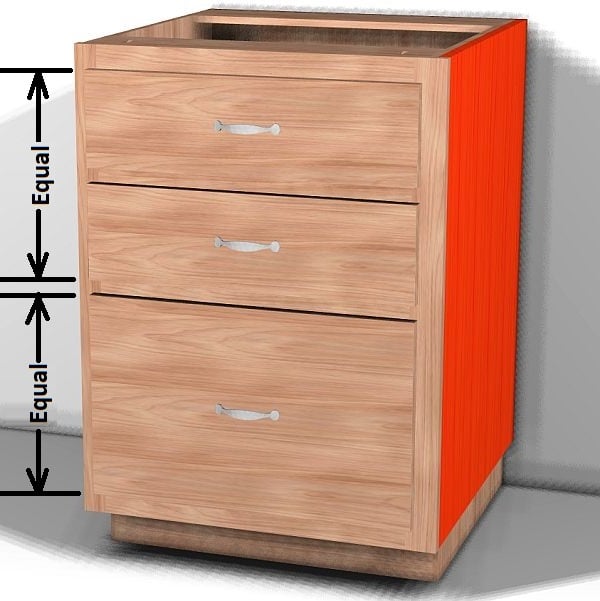

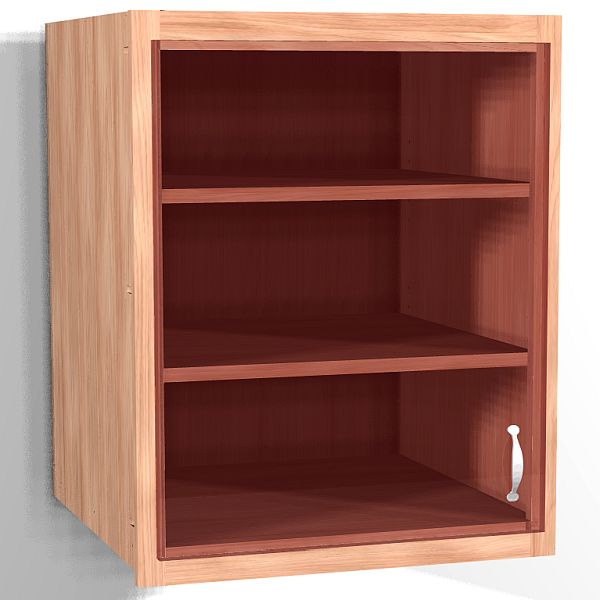

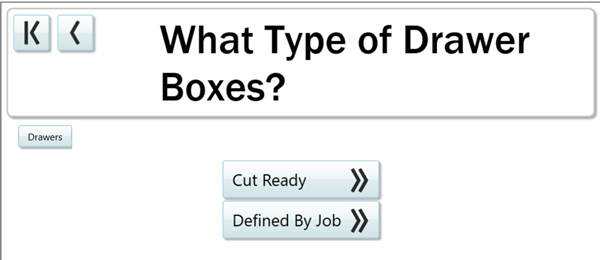

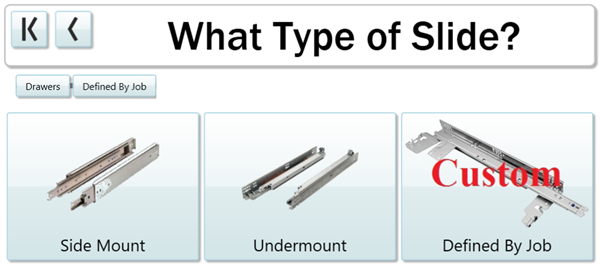

You tell him what you want and he creates a program to make it. Whether it is cabinets, doors, moldings or furniture, Artie will program it for you!

These are not pre-programmed libraries. No part programs exist in the control until Artie creates them.

He is already capable of programming tens of millions of unique products and is constantly learning how to make and do more and more new things.

Artie is easy enough that virtually anyone can work with him with little or no training.

Cut Ready is currently available on two machines from Thermwood:

.jpg?width=300&name=cut_center_cnc_router_image%20(1).jpg)

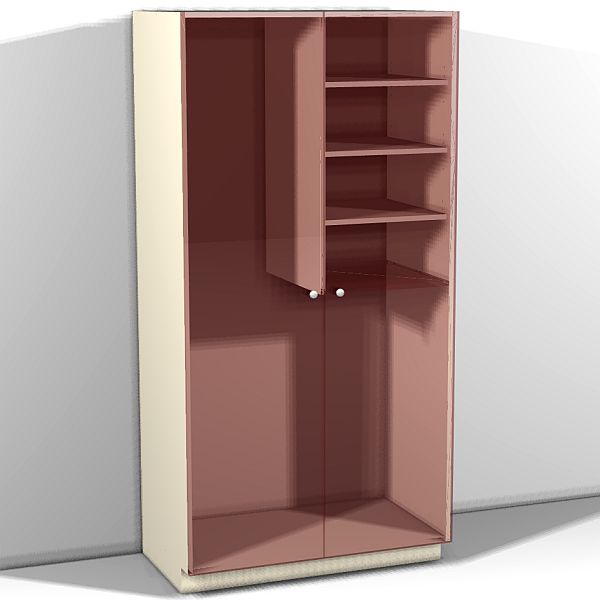

The Cut Center - requires neither a CNC programmer nor a trained machine operator. Artie moves beyond just programming to guide the operator through the entire production process real time. It is complete, fully contained with all the ancillary equipment smoothly integrated into a package that almost runs itself. Pretty much anyone can run a Cut Center.

The Cut Ready 43 - is a lower-priced machine that doesn’t need a CNC programmer, but does require a trained and somewhat skilled machine operator. With the Cut Ready 43 system, Artie offers help during the production process, but not quite to the extent that it does with a Cut Center.

Cut Ready Series Machines Detailed Comparison

More Info on the Cut Ready 43 with Artie Inside

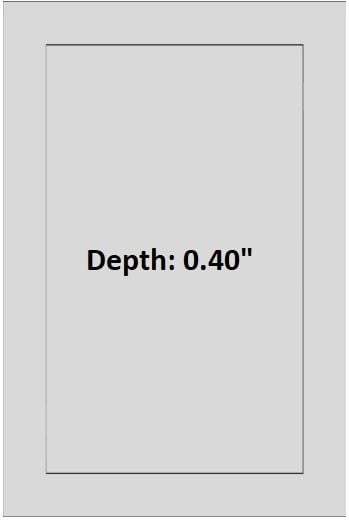

The Cut Ready 43 is equipped with a 5 by 8 table, a 21-position tool changer and a high flow vacuum hold-down system (additional table sizes and options are available).

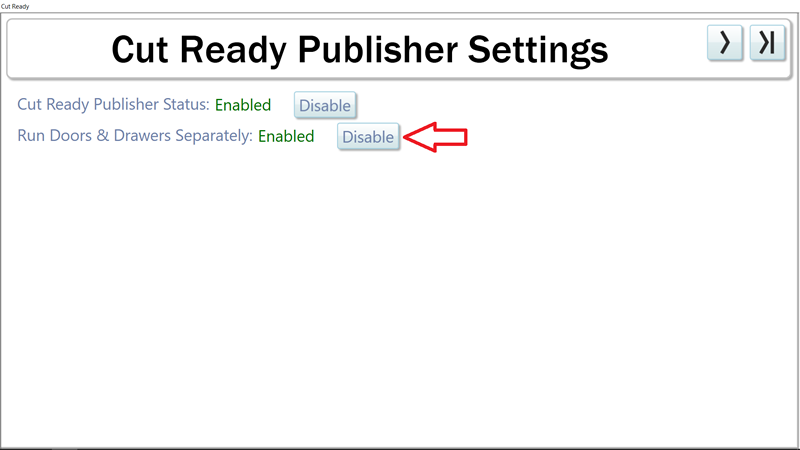

The Cut Ready 43 is intended to bring the magic of Artie to a lower-priced system. It features a full-sized vacuum table and, just like its big brother, doesn’t require a CNC programmer. Just like a Cut Center, it can help you quickly and easily create most products a cabinet shop would want to make without a CNC programmer (only operational training is required).

Since this is a CNC router at its core, you are free to program and operate it as a normal CNC router if you want, but the magic of Artie makes the Cut Ready 43 a whole new exciting experience!

For More Info on the Cut Ready 43, please click here.

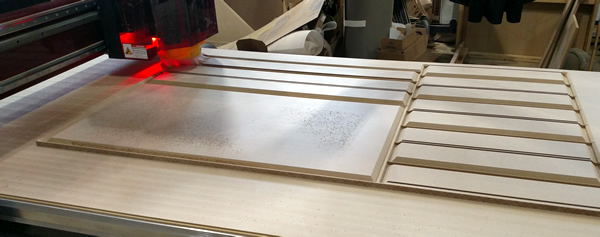

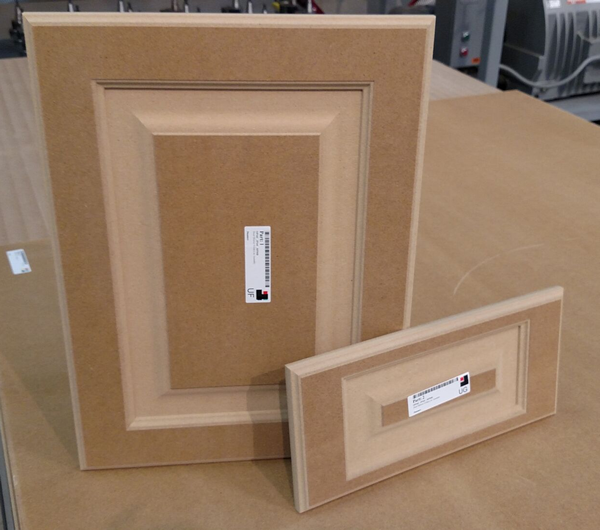

The video below shows the powerful Cut Ready 43 machining a door and matching drawer front in MDF using diamond tooling.

More Info on the Cut Center with Artie Inside

The Thermwood Cut Center is equipped with a 5'x10' table, easy sheet flipper, vacuum cups and a host of other software and equipment. It is all designed to help you save time and money, using an easy to operate and sophisticated combination of software and machinery that you can feel confident in.

We've taken the fear out of automation by combining our easy to use interface and years of experience in the industry to create a powerful tool that will allow you to focus more on your products, business, making money, and worry less about being intimidated by the technical details. It is complete, fully contained with all the ancillary equipment smoothly integrated into a package that almost runs itself.

The Cut Center is the ultimate in next generation CNC.

Your time is money, and the Cut Center helps you save more of both.

For More Info on the Cut Center, please click here.

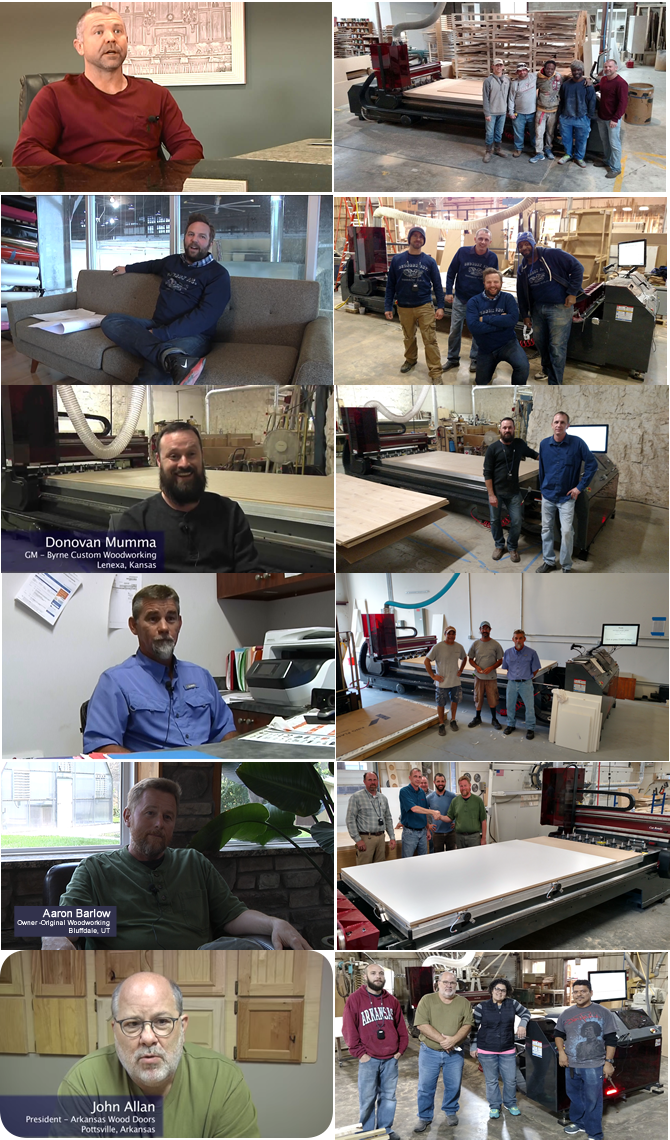

What Some of Our Cut Center Customers Are Saying...