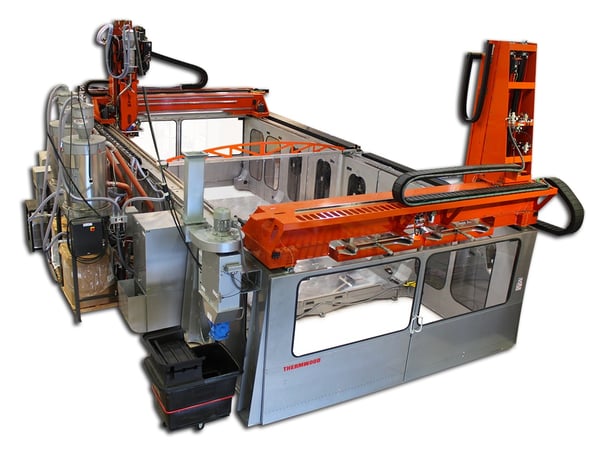

Installation of the world's largest composite 3D Printer is now complete at Local Motors. This massive Thermwood LSAM 10'x40' is ready to get to work making the Olli!

Thermwood LSAM 10'x40' - Ready to work!

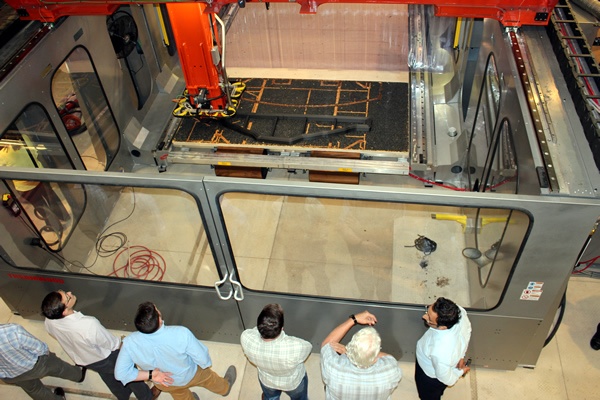

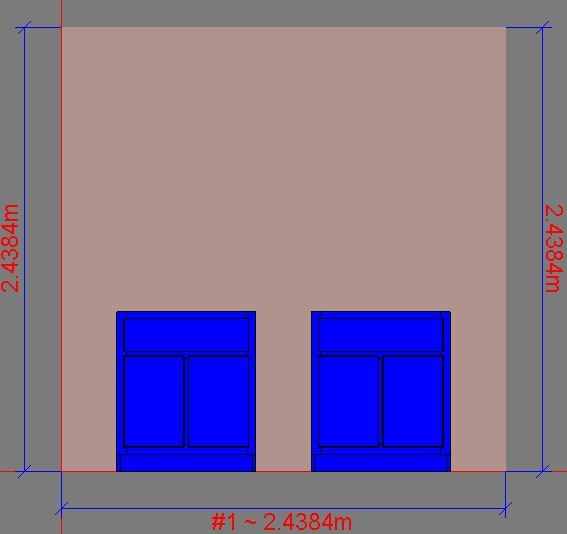

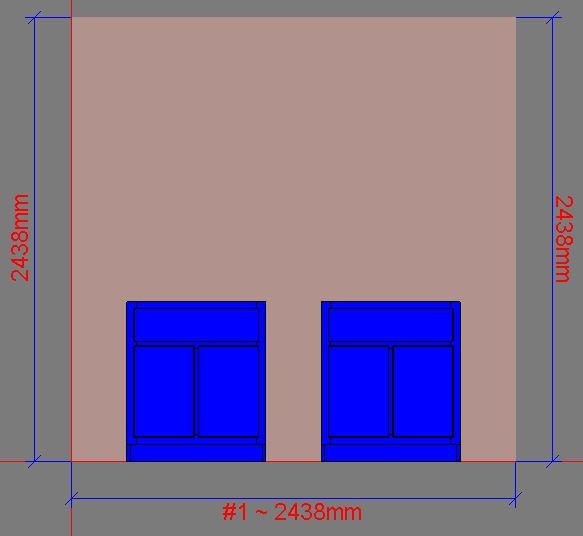

Looking down the working envelope from the print gantry side of the Thermwood 10'x40' LSAM

Looking down the working envelope from the print gantry side of the Thermwood 10'x40' LSAM

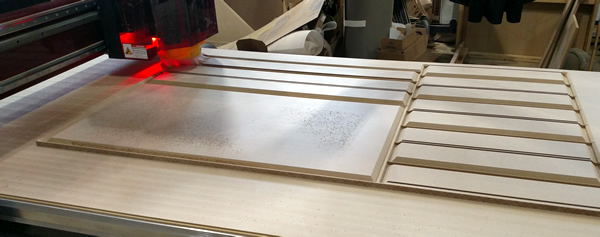

A part in the process of being printed on the Thermwood 10'x40' LSAM at Local Motors

A part in the process of being printed on the Thermwood 10'x40' LSAM at Local Motors

Looking down the working envelope from the print gantry side

Another view of the 10'x40' LSAM at Local Motors

Another view of the 10'x40' LSAM at Local Motors

A view from the trim gantry side of the Thermwood LSAM 10'x40' at Local Motors

A view from the trim gantry side of the Thermwood LSAM 10'x40' at Local Motors

About The Thermwood LSAM

Thermwood offers a line of dual gantry additive manufacturing machines which both print and trim parts on the same machine. These are large industrial additive manufacturing machines that can be up to 100 feet long.

LSAM (pronounced L-sam) represents an all new technology for large scale 3D printing of thermoplastic polymers. While other large scale additive efforts attempt to scale up small, filament-fed desktop printer techniques, LSAM is, at its core, designed for additive manufacturing of large structures using a fundamentally different approach

LSAM is different. The print process is different. The machine is different. The print head is different. The control is different. The software is different and the resulting parts are different.

LSAM is intended for industrial production. It is not a lab, evaluation or demonstration machine, but is instead a full-fledged industrial additive manufacturing system intended for the production of large scale components.

Although suitable for producing a wide variety of components, Thermwood is focusing on producing industrial tooling, masters, patterns, molds and production fixtures for a variety of industries including aerospace, automotive, foundry and boating.

About Local Motors

Local Motors is a ground mobility company focused on shaping the future for the better. Founded in 2007 with a belief in open collaboration and co-creation, Local Motors is a digital OEM, capable of micro-manufacturing, sales, service and operations all from a local footprint using a microfactory.

Local Motors is a ground mobility company focused on shaping the future for the better. Founded in 2007 with a belief in open collaboration and co-creation, Local Motors is a digital OEM, capable of micro-manufacturing, sales, service and operations all from a local footprint using a microfactory.

Meet Olli