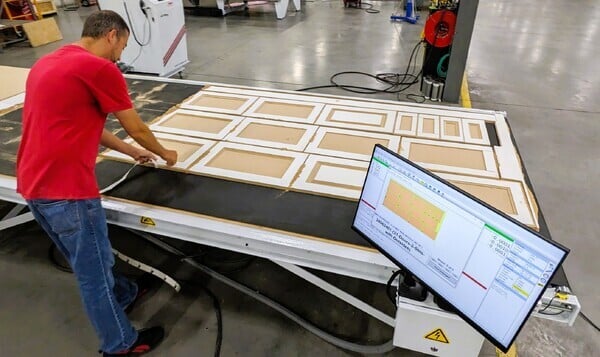

CabinetShop 43

Work Cell

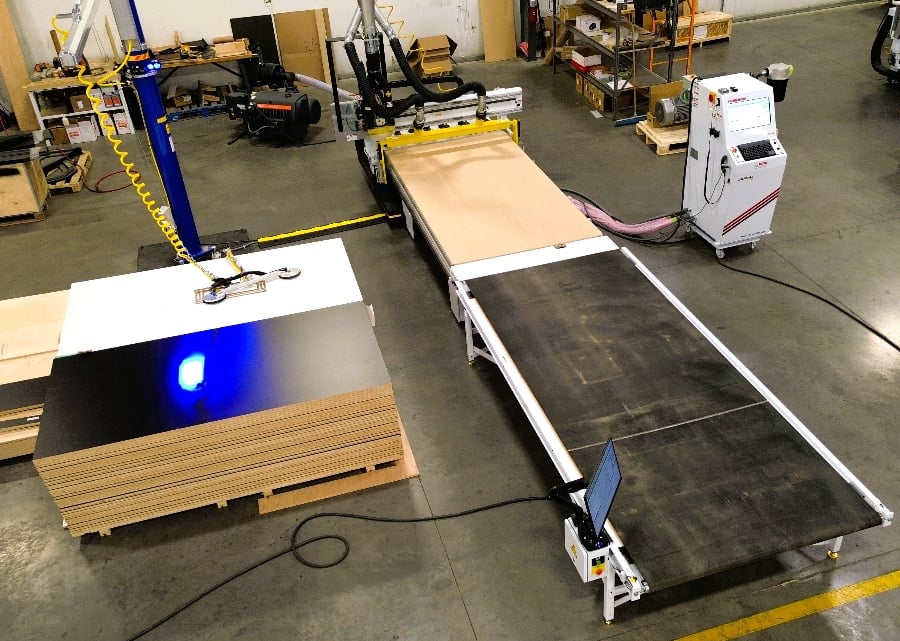

Advanced, Fully Integrated CNC Work Cell: Designed for custom cabinet, closet, and furniture builders. It includes an automatic off-load conveyor and a manual assist load system as well as a remote operator station to increase efficiency for producing custom boxes, doors, and drawer fronts.

CabinetShop 43 Work Cell 5'x10' Machining MDF Doors

What Makes it Special:

SuperControl System with Smart Router Technology:

-

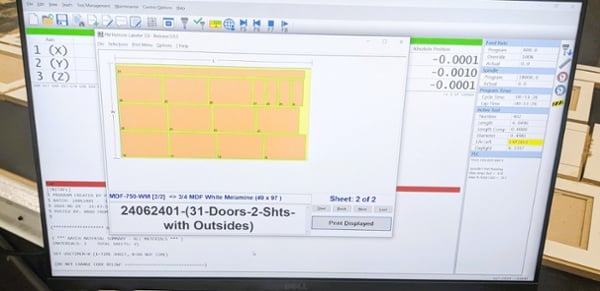

Control Nesting Software: Automatically generates high-yield nested parts from eCabinet Systems or any CAD software with DXF output.

-

Job Queuing: Accepts queued job files for continuous shift operations, guiding operators to the next job.

Manual Lift Assist System:

-

Ease of Use: Facilitates easy loading of sheet materials onto the router table.

-

Sequence Identification: Projects a light onto the next sheet to be loaded, guiding the operator seamlessly.

Remote Operator Station:

-

Touch Screen Monitor & Label Printer: Mounted on the conveyor table for easy access, enhancing efficiency in loading materials and applying labels.

Heavy-Duty Spindle & Tool Changer:

-

12 HP Spindle: Supports a wide variety of cutting tools with a 21-position automatic tool changer.

-

High-Flow Vacuum Hold-Down System: Securely holds materials on a 5’ x 10’ table, equipped with automatic programmable pop-up pins for precise sheet location.

Machining & Off-loading Process:

-

Automated Vacuum System: Cleans the work surface post-machining and automatically off-loads the finished sheet onto a conveyor.

-

Operator Tasks: During machining, operators can label, sort, and remove machined parts, ensuring a streamlined workflow.

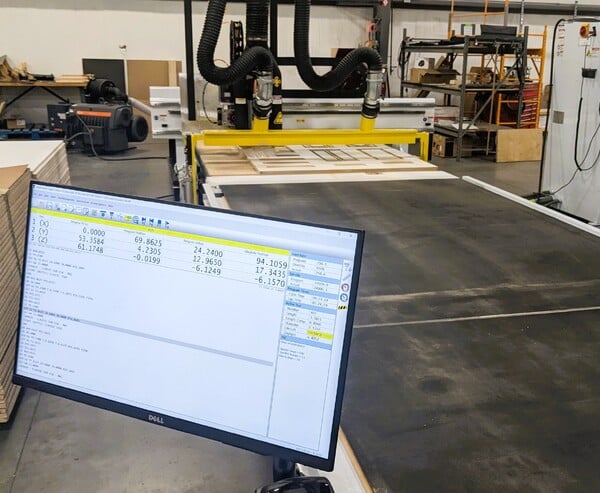

Ultra 6 SuperControl:

-

Storage & Intelligence: Boasts 1TB of solid-state memory storage, leveraging Smart Router technology for user-friendly, intelligent machine operations.

The CabinetShop 43 5'x10' Work Cell is engineered to optimize productivity, precision, and ease of use, making it an essential asset for custom cabinet and furniture manufacturing.

Key Features:

-

Available Table Sizes:

5'x10' (21 tooling positions & dual pipe dust collection)

-

Speed: Indexes at 2,800 IPM

-

Thermwood SuperControl with Smart Router Technology

-

1 TB of memory storage

-

12 HP HSD Spindle (3,000-24,000 RPM)

-

21 Position Bar Style Automatic Tool Changer

-

Fixed 5 ft by 10 ft High Flow Vacuum Table with Moving Gantry

-

Machine speeds up to 2,800 IPM

-

Automatic High Tolerance Tool Length & Diameter Measurement

-

Automatic Programmable Pop-Up Pins

-

Full Table Off-Load Rake w/Integrated Dust Collection

-

Powered Out-Feed Conveyor (61”x144”)

-

Remote Fully Functional Operator Station with Touch Screen Monitor and Label Printer

-

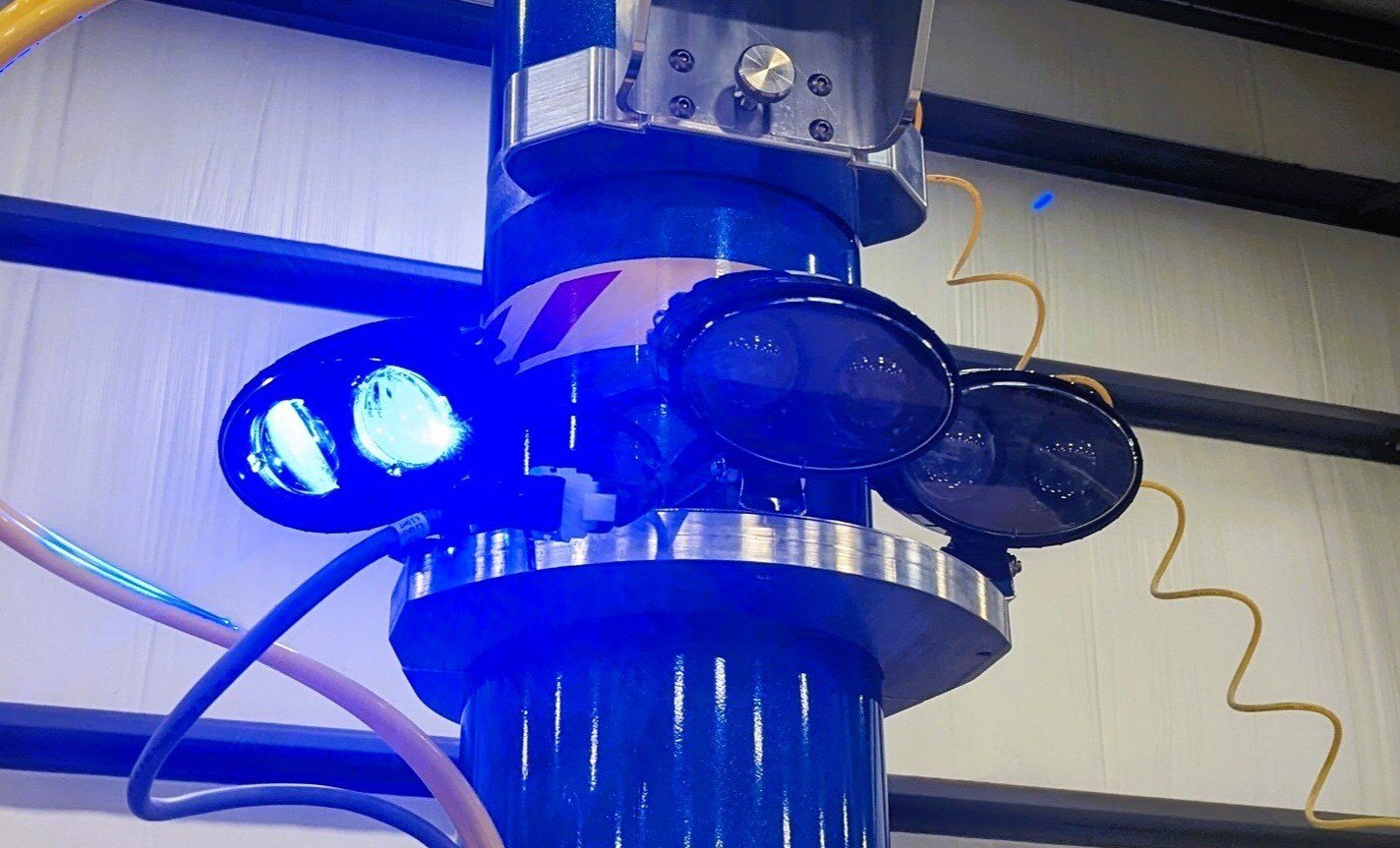

Manual Lift System with Automatic Sequence Light Sheet Locator System

-

Personal Pause FOB

-

Automatic Lubrication System

-

Three-Dimensional Laser Compensated Axis Alignment

-

Intelligent Servo Drives Throughout

-

Machine Training and Installation

-

Free Lifetime Phone, Forum and Email Support

-

Lifetime Machine Support from Thermwood’s Legendary Service and Support

Smart Router Technology

- The basis of a Smart Router is that it knows the job it is doing so it can help in ways no ordinary router can. It saves material, saves labor, is easy to use and is easy to maintain.

- Smart Routers live on the web. They access updates on the web, can be accessed and serviced through the web and apps let you monitor and manage your Smart Router using your smart phone or tablet.

Save Material

- Easily nest on material left from other jobs. This means a large savings each year for off-fall reuse.

- Recover from a broken tool without scrapping the sheet you are cutting or restarting the job. This saves a lot over time.

- Smart nesting. Control Nesting will automatically adjust the program for smaller parts using skins or tabs.

- Defective material. Easily nest around the defect, allowing you to use the sheet.

- Should parts start to move, Smart Routers can be instructed to complete the sheet without scrapping any more parts by leaving a skin. This skin is removed by hand, saving valuable parts and eliminating rework.

- Easily fly cut the spoilboard in the middle of a job. Maintaining a good working spoilboard surface with ordinary routers is involved and prone to problems.

- Perform back side operations on a full sheet rather than process the back of parts one at a time. This not only saves labor but also avoids errors from handling a lot of individual parts.

- Smart Router technology alerts you when a prominent, highly visible part is about to be processed so you can hand select the sheet with good grain and no flaws. This avoids scrapping important parts due to small flaws.

Save Time

- Send a design file from almost any design software, even a properly formatted DXF file, to the machine and it does everything else. No need to develop inflexible posted CNC programs, the machine does it all automatically.

- Remake parts. At the end of a job, simply scan the label on any part or parts and it nests them on the remaining material and cuts them. You can remake parts from a previous job the same way.

- Easily recover from problems like broken tools, bad material, parts moving, etc. without having to develop new CNC programs.

- Load your entire eCabinet Systems product line in the machine and then select, resize and run any product or combination of products without developing a CNC program for each job. It even lets you change material thickness without programming.

- When selecting a product to run, Smart Router technology shows not only the alphanumeric name but may also an image of the item to help avoid errors.

- Pause technology. A pause button clipped to an operator’s belt can stop the machine, so the operator is free to perform other tasks away from the control.

- Machining backside operations on the full sheet rather than on individual parts saves a lot of labor. Also, it is more likely to make errors and scrap parts when they are handled one at a time.

Easy to Use

- Smart Router technology will nest and run part data from major cabinet design software packages. They run properly formatted DXF files from about anything. Files from multiple sources can be easily nested together in a single job.

- Easy file transfer between machines. Since all factors unique to a machine are handled within the machine, design files can be transferred between Smart Routers, regardless of size or configuration and it will run properly plus you will get the exact same parts.

- Easily process material whose thickness varies from the thickness specified in the original design. Simply input actual material thickness at the beginning of a job and the machine makes all necessary adjustments automatically.

- Smart Router technology informs you how many steps are in the program, what the current step is, and what it is doing.

- Smart labels. For jobs with more than one item, symbols tell you which part goes with which item, saving a lot of sorting time. Diagrams on the label tell you which edges get edge banded.

- Smart Router technology runs eCabinet Systems generated assembly marks. This pattern of dots, machined into mating joints show which parts fit together. This cuts assembly time on most items more than in half.

- Smart tooling technology. This makes it really easy when you run different materials that each require different tooling (wood and aluminum for example). Simply specify the material and the machine will select the correct tools and run them at the proper speeds.

- Smart Router technology keeps track of tool use and will alert you when a tool should be changed, before it starts cutting bad parts. When a tool gets dull you can even have it switch to a backup tool, automatically.

- Smart Router technology can machine a profile edge without a profile tool, by tracing over the edge multiple times with standard tools. It even works on curved moldings. This saves a lot for any shop that makes custom moldings.

Easy to Maintain and Service

- Smart Router technology tracks use and informs you when it is time to clean a filter, lubricate items or perform other routine maintenance.

- When an error is encountered, a diagram will be shown of the likely causes and recommended remedies.

- A complete searchable maintenance and operating manual is accessible right at the control.

- Smart Router technology provides videos of how to perform virtually all service functions, at the control.

- Smart Router technology also display a three-dimensional CAD drawing of the machine which you can rotate explode and zoom to see how parts fit together and accurately identify every part of the machine. This avoids errors when ordering parts and gets you back running quickly. Smart Router technology enables servicing, reconfiguring and tuning over the Internet.