Discover the latest in our LSAM series! Today, we’re highlighting Thermwood’s Patented Chilled Compression Wheel — engineered for precision, bead consistency, and enhanced bonding strength, delivering fused structures that surpass aerospace standards. See how Thermwood’s LSAM continues to lead in Large Format Additive Manufacturing!

𝐒𝐨𝐦𝐞 𝐩𝐨𝐰𝐞𝐫𝐟𝐮𝐥 𝐚𝐝𝐯𝐚𝐧𝐭𝐚𝐠𝐞𝐬:

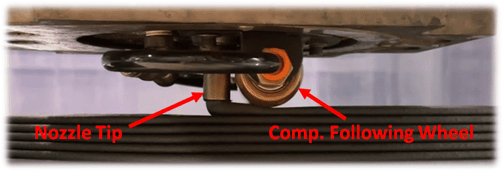

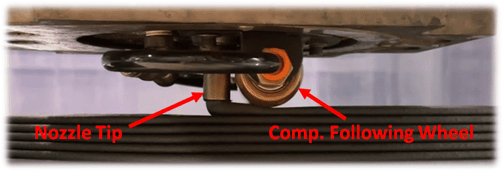

• Finishes the bead's final shape and dimension

• Provides important active bead compaction

• The nozzle tip is slightly above the finished bead height

• Nozzle tip does not drag through the material to form the final shape

• Prevents excessive material build up on the nozzle

• Temperature controlled only to prevent polymer affinity (sticking to wheel)

• Removal of inter-bead voids

• Consistency in printed composite microstructures

• Enhances interlayer bonding

• Enhances lateral bead to bead solidity

• Layer-to-layer fusion is over 50% GREATER in strength when compared to methods that utilize a tamping device or those that have no application device at all.

• This results in fused, solid structures that hold vacuum exceeding aerospace standards, 𝐰𝐢𝐭𝐡𝐨𝐮𝐭 the need for fill compounds or sealants.

𝐋𝐒𝐀𝐌 𝐒𝐲𝐬𝐭𝐞𝐦𝐬 𝐎𝐟𝐟𝐞𝐫:

- Superior Print Consistency

- Dynamic Control of Print Temperature

- Large Scale Focused Slicing Software

- Confidence Through Thermwood's Legendary Training, Service and Support