Just like a smart phone does more than make phone calls, a “smart-router” does much more than route parts. The “more” in a smart-router saves material and labor and makes it really easy to use. A smart-router does cost more but is substantially more profitable, making it a much better overall investment.

Thermwood smart-routers process part programs two ways:

- The traditional way by using CNC program output from virtually any design software. Thermwood smart-routers can even run existing programs written for other brand machines (even if those programs contain codes specific to that machine). This means, with a Thermwood smart-router, you can use software configured for almost any machine and you can run programs you already have without reprogramming. Thermwood smart-routers are pretty much compatible with anything.

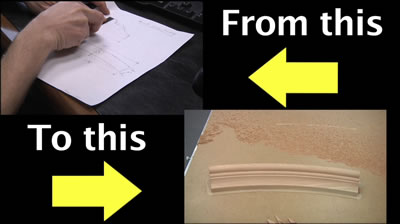

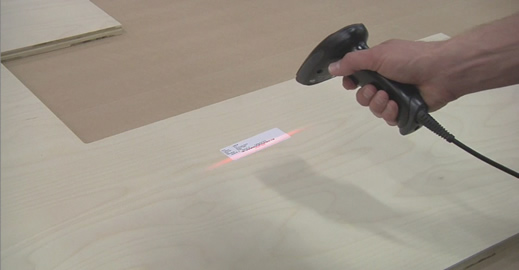

- Instead of using traditional CNC programs developed with software and a PC, Thermwood smart-routers can also use part information directly, and create the actual cutting programs within the machine itself. Major software vendors offer database output to Thermwood smart-routers, and any software that can output DXF files will work with Thermwood smart-routers. You send the design to a Thermwood smart-router and it, rather than you, worries about how to make the parts. This offers significant advantages.

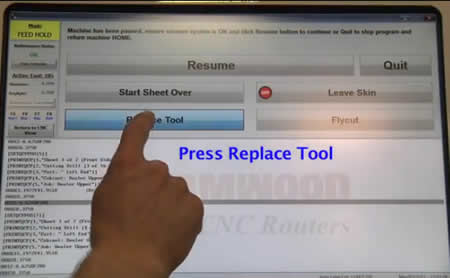

Replacing bad or scrap parts is really easy with a

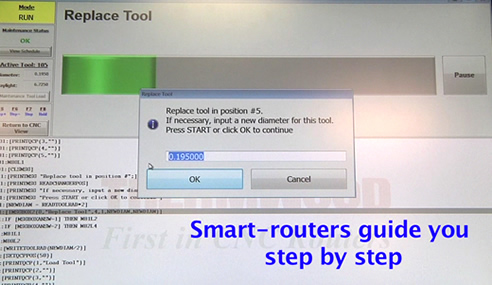

Replacing bad or scrap parts is really easy with a  During program operation, smart-routers tell you what they are doing and offer instructions every step of the way. They tell you how many steps are in the program,what step they are on and what step is coming up next.

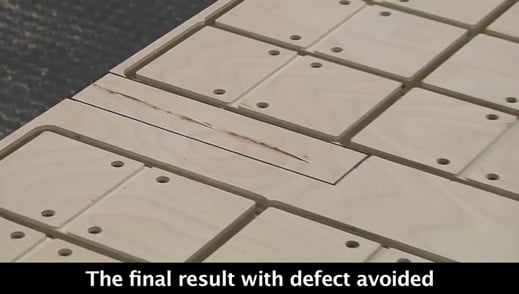

During program operation, smart-routers tell you what they are doing and offer instructions every step of the way. They tell you how many steps are in the program,what step they are on and what step is coming up next.  This feature can save you a lot of material, which in turn can save you a lot of time and money.

This feature can save you a lot of material, which in turn can save you a lot of time and money.