Thermwood Automatic Flycut Routine

More info on our line of powerful and versatile 3 Axis CNC Routers: https://bit.ly/4cK0qmW

Posted by Duane Marrett on Wed, Jul 03, 2024

Tags: 3 Axis, Announcements, flycut, spoilboard, Flycut Routine

More info on our line of powerful and versatile 3 Axis CNC Routers: https://bit.ly/4cK0qmW

Posted by Duane Marrett on Wed, Mar 09, 2022

Tags: Thermwood, New, 3 Axis, Announcements, cabinets, nested based, Furniture, AutoProcessor, AutoProcessor 43

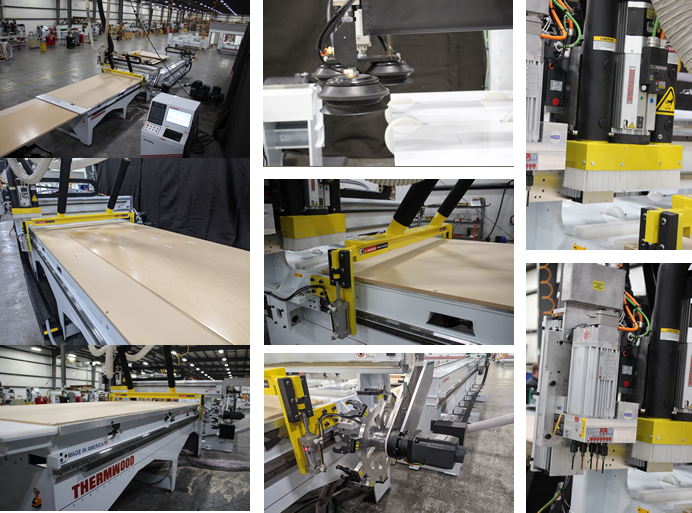

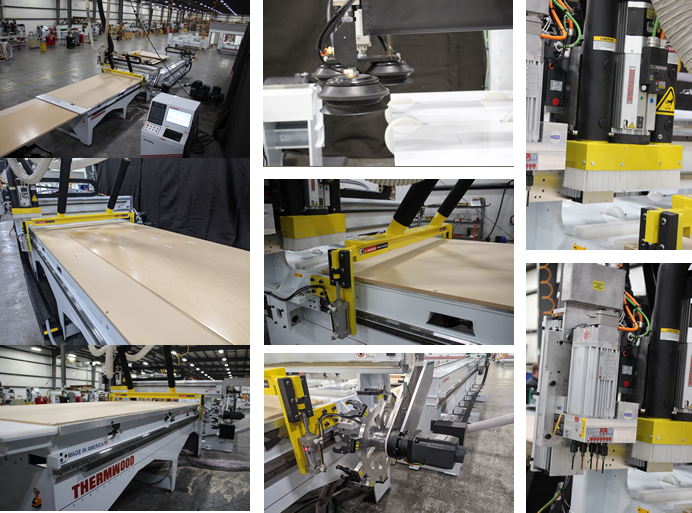

Thermwood's AutoProcessor 43 Machining Center is an all-new complete, nested-based, CNC routing system for machining cabinet boxes, custom furniture and basically any nested type of sheet product.

AutoProcessor 43

The AutoProcessor 43 is fully automatic from labeling and positioning of the sheets, to machining and off-loading the machined parts.

With each cycle, the machine simultaneously and automatically:

Standard Features

Well Equipped with Features/Options

A direct driven spindle with a speed range up to 24,000 RPM. the High Frequency Spindle is cooled with an electric fan for quieter running and contains ceramic bearings for longer life and for less maintenance. The 12 HP (9kw) spindle provides the user with a heavy duty, precision spindle for high performance and reliability. Standard

10 Position Rotary Automatic Tool Changer Includes (10) ISO-30 Tool Holders and collets. Max tool size is 2" (50mm) in diameter and 3.25" (83mm) in length. Standard (optional HSK63F)

The Automatic CNC Labeler System labels the sheet before the machining operation. The labels assist with sorting and assembling finished parts. Optional

Automatically loads sheets up to 60" x 120" (1.5m x 3.0m) to assist operator with unloading the machine and automatically position the sheet. Each individual sheet is elevated and positioned by a series of programmable vacuum cups. A steel rake is mounted in front of the router motor and travels with the machine gantry allowing parts to be removed off the front of the table. Dust extraction/table sweep occurs during the rake process. Standard

The drill unit is a vertical boring head with five vertical spindles. The spindles are on 32mm centers. The drill unit can be independent. Optional

Universal Vacuum System is a unique method for holding panels to the table top for machining. A sheet of MDF is used as a work surface on the top of the table. The high flow pump vacuums through the work surface, holding the part to the table. Pumps are available in different sizes. Optional

About Thermwood Corporation

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood has also become the technology and market leader in large scale additive manufacturing systems for thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) machines that both 3D print and trim on the same machine. These are some of the largest and most capable additive manufacturing systems ever produced and are marketed to major companies in the aerospace, marine, automotive and foundry industries as well as military, government and defense contractors.

Posted by Duane Marrett on Wed, Sep 11, 2019

Tags: Thermwood, CNC, plastics, 3 Axis, CNC Router, plastic trimming, Success Story, Traco Manufacturing

When you purchase a three or five axis CNC router or an LSAM (Large Scale Additive Manufacturing) system from Thermwood, you get a dependable machine, a superior control, reliable performance and the best service and support in the business.

When you purchase a three or five axis CNC router or an LSAM (Large Scale Additive Manufacturing) system from Thermwood, you get a dependable machine, a superior control, reliable performance and the best service and support in the business.

We don't just consider you a customer, but as a partner, friend and family member. We believe in helping each other through a genuine relationship of mutual trust so that we are both successful together.

Take a listen to Dan Jachimowicz of Traco Manufacturing, Inc. located in Batavia, NY and his two sons, Dan Jachimowicz, Jr and Jameson Jachimowicz as they talk about their history with Thermwood, their eight Model 45 CNC routers and how the quality, reliability, longevity and ease of use of the machines have helped to grow their business to where it is today. Making Traco Manufacturing one of the leaders in taking design and engineering ideas and quickly developing them into high quality plastic prototypes and products.

Dan Jachimowicz and his two sons, Dan, Jr and Jameson at Traco Manufacturing, Inc in Batavia, NY

The Thermwood Multi-Purpose 45 is a heavy-duty, high-performance three axis CNC router designed for real-world production.

Available in either single or dual spindles (with optional rotary axis), the Model 45 is used in the machining of composites, tooling boards, plastic sheets, aluminum, cabinets, solid wood, millwork, phenolic, display fixtures, nested based panels and much more.

This versatile machine is available in a variety of table sizes and has enough standard features and options to get the job done.

Model 45 Dual Spindle 5'x5' Single Table |

Model 45 5'x10' Single Table |

Posted by Duane Marrett on Tue, Jul 16, 2019

Tags: Thermwood, 3 Axis, Trade Shows, AWFS, Model 45, Las Vegas, Why Purchase a Thermwood, Cut Ready, Cut Center, No Programming, Save Money, Easy CNC, Artie, Combination Cabinets

The 2019 AWFS Show (July 17th-20th) promises to be an exciting opportunity to visit Las Vegas and see the very latest technology from Thermwood! Like the award winning Thermwood CUT CENTER (make virtually anything a cabinet shop would want to make - with no programming) and the powerful and versatile MODEL 45 with a pod system (machining solid wood, plastic and aluminum).

The 2019 AWFS Show (July 17th-20th) promises to be an exciting opportunity to visit Las Vegas and see the very latest technology from Thermwood! Like the award winning Thermwood CUT CENTER (make virtually anything a cabinet shop would want to make - with no programming) and the powerful and versatile MODEL 45 with a pod system (machining solid wood, plastic and aluminum).

This year, Thermwood is proud to demonstrate the award-winning CUT READY CUT CENTER (with Artie inside to help you quickly and easily create most products a cabinet shop would want to make without a CNC programmer).

You'll have the opportunity to see just how easy it is to run this powerful machine. Just tell it what you want, and it makes it...it is that easy!

We'll be demonstrating live during the show, and you can be part of it by helping to operate the CUT CENTER. Please visit our booth (#7425) and speak to a Thermwood representative to get your hands on this exciting machine!

Despite the cute name, Artie is actually a cutting edge, artificial intelligence engine inside the CUT READY control.

You tell him what you want and he creates a program to make it. These are not pre-programmed libraries. No part programs exist in the control until Artie creates them. This is nothing less than a bold next step in the evolution of the CNC router.

Artie is already capable of programming tens of millions of unique products and is constantly learning how to make and do more and more new things. Artie is easy enough that virtually anyone can work with him with little or no training.

We will also be demonstrating solid wood, plastics and aluminum utilizing a pod system and a horizontal aggregate on the Thermwood MODEL 45.

We will also be demonstrating solid wood, plastics and aluminum utilizing a pod system and a horizontal aggregate on the Thermwood MODEL 45.

The heavy-duty MODEL 45 is designed for a variety of functions including the machining of rotary operations when equipped with our optional C-Axis. This expands the capability of this already useful machine to include volutes, carvings, chair parts, stair components and much more. The MODEL 45 is also equipped with smart-router technology that helps save labor and material, are easy to use and will make you a lot more money than ordinary routers.

Both the CUT CENTER and the MODEL 45 will be on display and cutting live at AWFS 2019 (Thermwood booth #7425). We will also have several displays featuring the powerful new Combination Cabinets (this new tool allows you to easily create a large bank of connected cabinets with multiple sections).

Both the CUT CENTER and the MODEL 45 will be on display and cutting live at AWFS 2019 (Thermwood booth #7425). We will also have several displays featuring the powerful new Combination Cabinets (this new tool allows you to easily create a large bank of connected cabinets with multiple sections).

Using Combination Cabinets can bring real savings to your production - Cut Ready Combination Cabinets can save you time, material and money!

Make plans to see this exciting new technology in person and attend AWFS 2019 (July 17th-20th) at the Las Vegas Convention Center - Las Vegas, NV or contact us at 800-533-6901 for more information.

Posted by Duane Marrett on Wed, Mar 27, 2019

Tags: Thermwood, CNC, CNC Routers, Woodworking, 3 Axis, CNC Router, Cut Ready, Cut Center, cabinets, doors, moldings, closets, Furniture, No Programming, Testimonials, Cut Center Impressions, Easy CNC, drawer boxes, AUM Wood Products

Thermwood's Award Winning Cut Center is an exciting alternative to traditional CNC routers - just tell the machine what you what to make and it does it...it is that simple! No programming is required! Also, you can operate the system as a CNC router in the traditional manner, running programs generated with virtually any CNC software.

Here we present a short video featuring a new Thermwood Cut Center owner and his impressions of the machine and its capabilities.

Take a listen to Matt Schiller of AUM Wood Products in Spicer, MN as he discusses their Thermwood Cut Center and what the machine is doing for his business.

Below are a few more Cut Center owner impressions as well - take a listen to Larry Crutchfield of Alpha Woodworks in Dothan, AL, Tim Richardson of Timberwood Properties in Leesburg, FL, Aaron Barlow of Original Woodworking in Bluffdale, UT, Michael Bednark of Bednark Inc. in Brooklyn, NY, John Allan of Arkansas Wood Doors in Pottsville, AR and Donovan Mumma of Byrne Custom Woodworking in Lenexa, KS as they discuss their new Cut Centers and what the machine is going to do for each business.

Operate as a Cut Center with NO Programming or as a Traditional CNC Router, running programs generated with virtually any CNC software.

Posted by Duane Marrett on Mon, May 07, 2018

Tags: Thermwood, CNC, CNC Routers, Woodworking, 3 Axis, CNC Router, Cut Ready, Cut Center, cabinets, doors, moldings, closets, Furniture, No Programming, Testimonials, Cut Center Impressions, Easy CNC, drawer boxes, Alpha Woodworks

Thermwood's Award Winning Cut Center is an exciting alternative to traditional CNC routers - just tell the machine what you what to make and it does it...it is that simple! No programming is required! Also, you can operate the system as a CNC router in the traditional manner, running programs generated with virtually any CNC software.

Here we present a short video featuring a Thermwood Cut Center owner and their impressions of the machine and its capabilities.

Take a listen to Larry Crutchfield of Alpha Woodworks in Dothan, AL as he discusses their Thermwood Cut Center and what the machine is doing for their business.

Take a listen to Larry Crutchfield of Alpha Woodworks in Dothan, AL as he discusses their Thermwood Cut Center and what the machine is doing for their business.

Below are a few more Cut Center owner impressions as well - take a listen to Tim Richardson of Timberwood Properties in Leesburg, FL, Aaron Barlow of Original Woodworking in Bluffdale, UT, Michael Bednark of Bednark Inc. in Brooklyn, NY, John Allan of Arkansas Wood Doors in Pottsville, AR and Donovan Mumma of Byrne Custom Woodworking in Lenexa, KS as they discuss their new Cut Centers and what the machine is going to do for each business.

Operate as a Cut Center with NO Programming or as a Traditional CNC Router, running programs generated with virtually any CNC software.

Posted by Duane Marrett on Thu, Mar 08, 2018

Tags: CNC, 3 Axis, CNC Router, Cut Ready, Cut Center, Video, Testimonials, Byrne Custom Woodworking

Article republished with permission from "Technology helps underground shop take on any custom project" on www.woodworkingnetwork.com by Karl D. Forth

Byrne Custom Woodworking works to focus on the details customers want.

“I find that customers these days are so much more educated in the level of craftsmanship and attention to detail,” said company president Ian Byrne. “Any personal details such as carvings or other architectural elements that we can include in our projects are always so appreciated.”

The Lenexa, Kansas, company makes custom cabinets and architectural millwork, both for residential and commercial customers.

“We do quite a lot of church projects,” Byrne said. “I am really happy that the design trends have gone back to Gothic and traditional styles. It has been quite adventurous designing and producing some of these elements with our CNC.”

Byrne has been using a Thermwood Cut Ready CNC machining center to handle the special requests from customers.

Thermwood Cut Ready CNC router has helped Byrne achieve maximum panel yield.

Thermwood Cut Ready CNC router has helped Byrne achieve maximum panel yield.Ian Byrne started the business in nearby Kansas City in 1989. Fifteen years ago, he moved the company underground – to a former limestone mine with vast galleries and underground space. This underground world is home to dozens of businesses and is known officially as the Meritex Lenexa Executive Park.

The move underground came about when Byrne purchased a large panel saw that was operated by a company making laminate casegoods that planned to close. That company had a large SCMI panel saw and edgebander. The panel saw, it turned out, was too large to move out of the cave.

So Byrne moved in, and they’ve been happy in their underground space since.

The caves resemble a movie set, where it never gets too hot or too cold. When it is bitterly cold outside, it is still warm deep in the caves. And the lack of large temperature and humidity extremes minimizes wood changes.

“The upside is a controlled environment with regard to humidity and temperature. It is very comfortable all year round and the wood loves it,” Byrne said. “The downside is we have to transport our product for finishing to another facility.”

The finish shop is located above ground, in West Bottoms near downtown Kansas City.

Customers and markets

Most work is residential, and general manager Donovan Mumma said that some larger residential jobs are handled as a commercial job would be.

One recent job was for a large 30,000 square foot house, including large walnut closet cabinets, gun cabinets, and pecky cypress.

Mumma said that alder was very popular, and has replaced cherry in many applications.

Also, reclaimed wood continues to be popular for furniture and faux beams. Byrne gets this wood from a number of sources, including old barns.

Byrne also makes plantation shutters, using paint grade basswood and poplar.

“We built a library for a client using walnut,” Byrne said. “They insisted that the shutters in the doors and windows also be fabricated using walnut. So we made the necessary jigs and tooling and the shutter department was born.”

Other projects have included a large curved desk with flex plywood, and many altars, candle stands and other pieces for churches.

They also make their own doors and drawers in house.

“Because we do so many varied projects and styles, it is nice to have the capability to fabricate two or four custom doors for a furniture piece when needed,” Byrne said. “It is also a good way to keep your employees busy during slower times. When really busy, we will buy out the doors and drawers.”

Byrne doesn’t use melamine or particleboard as a rule, unless is it requested. The company’s primary panel product is a UV-cured plywood sheet stock with birch or maple UV coated on both sides.

“We stay in the mid- to high-end market,” Byrne said. “I saw this material as a top of the line cabinet liner. The coating is extremely durable and looks classy. It also makes the finishing process a lot easier. Columbia Forest Products is one of the manufacturers.”

Altars made by Byrne for St. Francis. Byrne said he is happy that the design trends have gone back to Gothic and traditional styles.

Altars made by Byrne for St. Francis. Byrne said he is happy that the design trends have gone back to Gothic and traditional styles.Maximum panel yield

The Thermwood Cut Ready CNC router has helped Byrne achieve maximum panel yield, and cuts the offal pieces in a way so they can be used again. The operator follows instructions on the Cut Ready’s screen.

Mumma said that the Cut Ready comes with a library of face frame and frameless cabinet designs already installed. Byrne could use or modify those existing designs. Mumma also uses the Aspire program for 3-D modeling.

Cut parts are labeled with a barcode that includes job and part number, and a figure showing any edgebanding required.

Then the cut pieces go directly to the edgebander or to assembly. Mumma believes that the investment in the Cut Ready may have already paid off for the company.

There was a learning curve, and Byrne did hire a CNC programmer. Mumma said the company was not completely new to CNC. They did have a point-to-point machine, and had earlier outsourced some work to an outside CNC shop.

Mumma said the quality of the cut materials is better. Blind dadoes allow a box to be put together and stay together before glue and fasteners are installed. This also saves time in assembly.

Cut Ready also allows them to make certain pieces in house that they used to outsource. “The Cut Center is dummy-proof,” Mumma said.

They were able to use the existing Cut Center library on other jobs. Mumma said that Cut Center also keeps track of tool wear on different tooling spindles after a baseline time is entered.

“Versatility comes to mind at first thought,” Byrne said of the Thermwood. “I truthfully believe we can take on any project and with the combination of our expertise and the versatility of this machine, we will be successful.”

Thermwood Cut Ready allows them to make certain pieces in house that they used to outsource.

Thermwood Cut Ready allows them to make certain pieces in house that they used to outsource.Doors and drawers

Byrne has 20 employees, including two installers and two in the finishing shop.

Mumma said they use Cabinet Vision, and he also uses Google SketchupPro 3D modeling to visualize projects.

The door and drawer department, and another cut-out area can cut pieces on smaller machines.

The panel saw that couldn’t be moved is still in use and performs well. This is an SCMI Alfa 320 panel saw that is from about 1994. An SCMI edgebander from the same time period is also still in service. A Ritter edge sander is also used.

Dust collection is done the usual way, with metal pipes and a dust collector on the outside of the main shop area, also underground. Local schools take the sawdust to use on their own projects.

The door and drawer department, and another cut-out area can cut pieces on smaller machines. Cabinet Vision is used in the shop.

The door and drawer department, and another cut-out area can cut pieces on smaller machines. Cabinet Vision is used in the shop.Software and spirit

Byrne said his outlook for 2018 is good. “We have a great team of enthusiastic designers and craftsman and craftswomen. (We have) lots of work on the board and plenty of prospects in the wind.

“We have recently invested in software to integrate our technologies as one. I want to expand our procurement of sacred spaces projects. For centuries around the world, some of the most incredible craftsmanship can be found in the churches and cathedrals.

“I would like our company to be a part of that legacy!”

Ian Byrne’s creativity isn’t limited to wood. He is lead singer for The Elders, a Kansas City-based band that is planning a final year of concerts in 2018. “It’s all in the hands and the heart! I have also surrounded myself with great craftsmen and talented musicians. This has led to enjoying success in both fields.”

At a glance

Byrne Custom Woodworking

Lenexa, Kansas

Custom cabinets and architectural millwork

Employees: 20

http://www.byrnecustomwood.com

Posted by Duane Marrett on Tue, May 09, 2017

Tags: Thermwood, 3 Axis, 5 Axis, Trade Shows, SAMPE, LSAM, RUAG

SAMPE 2017 is right around the corner. This year’s SAMPE event is located at the Washington State Convention Center in Seattle, Washington. Dates for the event are May 22nd–25th. Thermwood will be exhibiting at this event in Booth F24, Hall A. You can register for the event at www.sampeamerica.org

Thermwood will be featuring our new Large Scale Additive Manufacturing (LSAM) system showing videos along with finished parts. The LSAM is a one of a kind system that features a print gantry for printing a variety of materials including ABS,PPS and ULTEM with carbon fiber and a trim gantry for the subtractive process. The LSAM is used for the production of tooling, molds, masters, patterns, fixtures and plugs used in a variety of industries including aerospace, automotive, boating, foundry and thermoforming.

Thermwood will be featuring our new Large Scale Additive Manufacturing (LSAM) system showing videos along with finished parts. The LSAM is a one of a kind system that features a print gantry for printing a variety of materials including ABS,PPS and ULTEM with carbon fiber and a trim gantry for the subtractive process. The LSAM is used for the production of tooling, molds, masters, patterns, fixtures and plugs used in a variety of industries including aerospace, automotive, boating, foundry and thermoforming.

Thermwood will also feature our new three axis APM system for machining and automatically inserting potted fasteners for the satellite industry. This new system was brought to the industry in conjunction with RUAG Space. The APM system machines and drills the panels, then automatically inserts the fasteners using a patented approach.

Of course we can’t forget the Thermwood line of three and five axis CNC machining centers. We have a large variety of different sizes and configurations ideally suited for the production, fabrication & trimming of wood, plastics, non-ferrous metals, composites and other advanced materials. These applications range from machining patterns and molds/plugs to trimming & machining production products for various industries such as woodworking, automotive, aerospace/aviation, military/defense and many more industries.

Although we won’t have any machinery at this event, we will have videos and parts for touch and feel. We will also have representation there to help with any questions that you might have.

Thermwood is a US based company with dealers and distributors worldwide. In addition to machine manufacturing and software development, Thermwood has a technical service organization that provides support, machine installation, training, retrofits, custom programming and production assistance. Please visit www.thermwood.com, call 1-800-533-6901 or email info@thermwood.com for more information.

Posted by Duane Marrett on Thu, Apr 07, 2016

Tags: CNC, 3 Axis, CNC Router, Cut Ready, Cut Center, Video, Testimonials

Thermwood's Award Winning Cut Ready Cut Center is an all-new alternative to traditional CNC routers for making custom cabinets and furniture with NO programming.

Here we present a short video featuring two new Thermwood Cut Center owners and their impressions of the machine and its capabilities. Take a listen to Michael Bednark of Bednark Inc. in Brooklyn, NY and Donovan Mumma of Byrne Custom Woodworking in Lenexa, KS as they discuss their new Cut Centers and what the machine is going to do for each business.

Posted by Duane Marrett on Thu, Jan 28, 2016

Tags: CNC, CNC Routers, Nested Base, 3 Axis, CNC Router, Cabinet, Model 45, Solid Wood, Phenolic, Display Fixtures

The Thermwood Multi-Purpose 45 is a heavy-duty, high-performance three axis CNC router available in either single or dual spindles with optional rotary axis used in the machining of cabinets, solid wood, millwork, phenolic, display fixtures and much more.

© Thermwood Corporation. All Rights Reserved