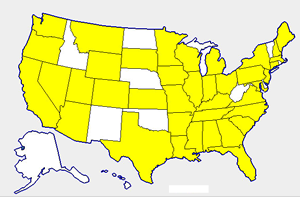

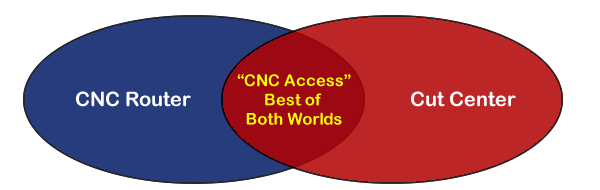

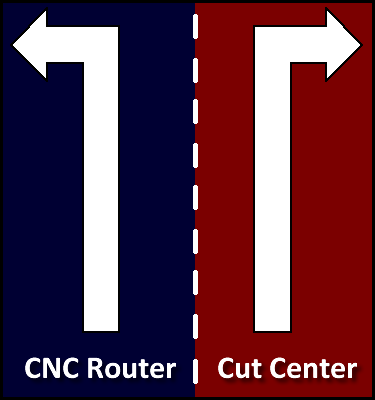

With the introduction of Thermwood’s “Cut Ready - Cut Center”, cabinet shops are faced with a fundamental decision about how to approach automating custom cabinet manufacturing. There are now two, distinctly different approaches, each with advantages and limitations:

With the introduction of Thermwood’s “Cut Ready - Cut Center”, cabinet shops are faced with a fundamental decision about how to approach automating custom cabinet manufacturing. There are now two, distinctly different approaches, each with advantages and limitations:

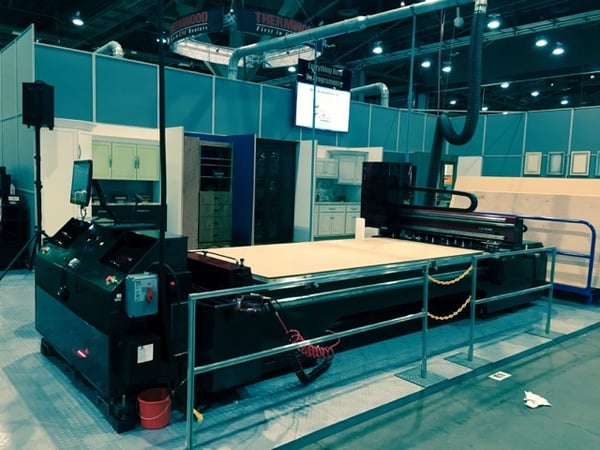

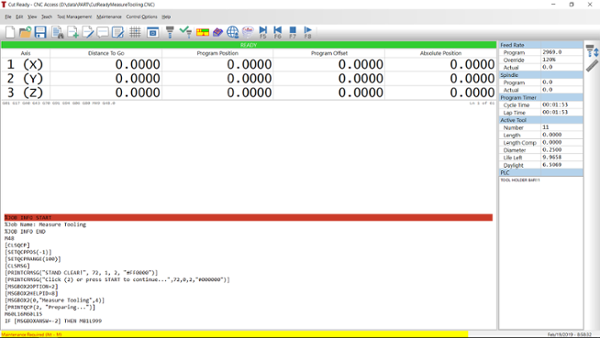

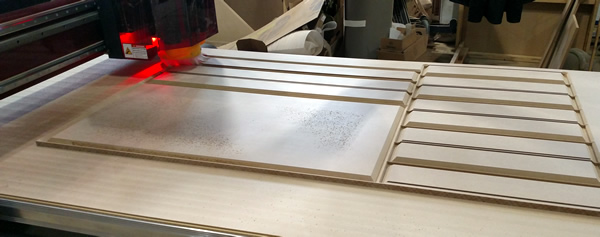

cnc router

Most shops are aware of CNC routers and how they work. You begin with cabinet design software that is used to design products and create the CNC programs needed to make the parts. Each software provider and machine manufacturer uses a somewhat different approach, but in the end you create what you want to make with software, on a separate computer, and send the resulting programs to the machine where it is cut. With this approach, there are no limitations as to what you can make, other than limits of the software package, your design and programming skills and how much programming time you want to spend.

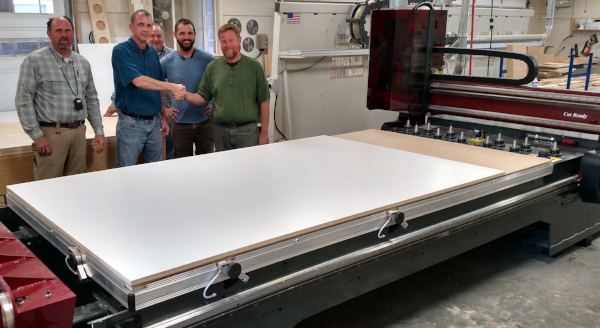

cut center

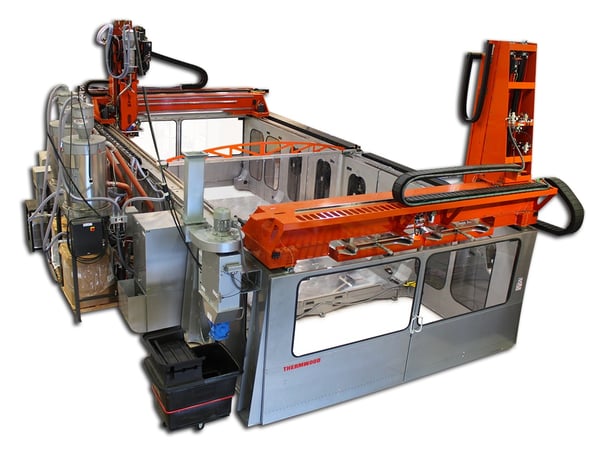

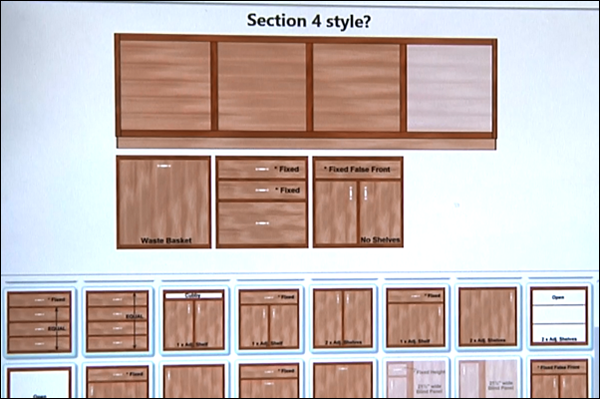

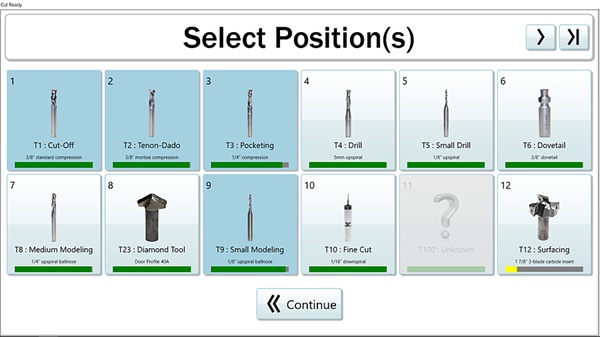

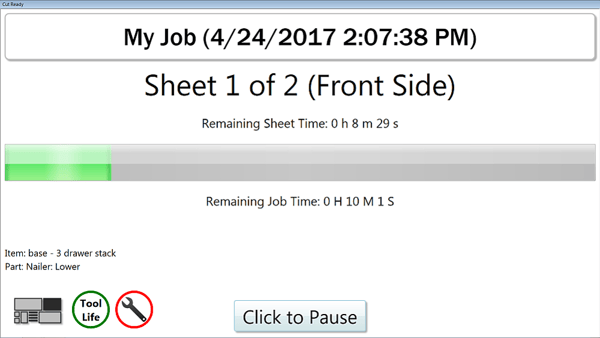

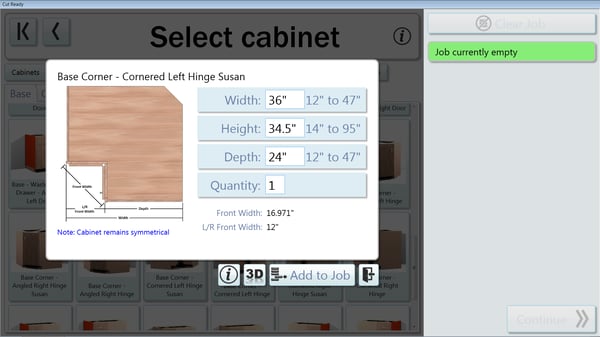

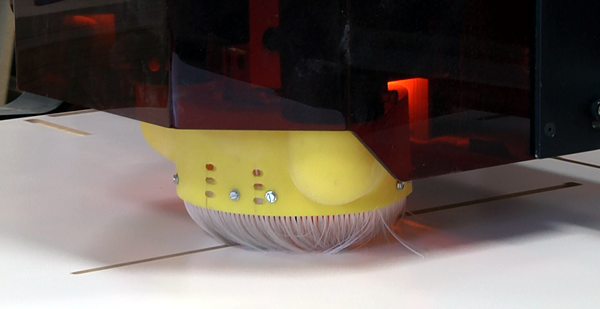

Cut centers take a different approach. With cut centers, everything is already in the machine. There is no separate design software or design computer. The machine itself knows how to make cabinets. Tell it how you want your cabinets made, frame or frameless, one or two sided material, assembly method…it offers you options and you select what you want. It then shows you all the cabinet configurations it knows how to make that way. Specify the size and it makes the parts for you. Because everything from product design to tooling and machine set-up is carefully controlled and coordinated, operation is a lot simpler, requiring virtually no technical training or skill. The touch screen control is intuitive so you focus on the product you are making rather than concentrating on making the product. The cut center is intended to make the bulk of products required by most cabinet shops with virtually no effort.

so which is best for your operation?

The answer probably depends on who you are and what you make. The “who you are” is defined by how enthusiastically you embrace computers, software and technology. A major advantage of cut centers is that there is no programming and it requires very little technical skill. If you embrace computers, software and don’t mind the programming time to get the complete flexibility and capability that you want, then a system that doesn’t need programming might not be for you.

-cut center advantage

If you are not very technical or don’t want to hire programmers, the cut center could offer a huge advantage. Even if you are technical, you may want to consider the amount of programming time and effort required to create programs for the products and jobs you plan to run. After all, even computer programmers buy software from others just so they don’t have to program everything themselves. Thermwood, working with professional cabinetmakers, has spent thousands and thousands of programming hours developing products the cut center can make. This is an ongoing effort, something you probably would not have time to do.

In general, if you don’t enthusiastically embrace technology, the cut center approach is probably better, but “what you make” is also important.

-cnc router advantage

If you seldom make the same thing twice and focus on truly custom products, your choice is probably design software and a CNC router, although, in these circumstances it may also be reasonable to continue making products using existing manual techniques. Sometimes programming and proofing something so it can run on a CNC router takes more time than just making it by hand, especially if you are only going to do it once. If most of what you do is a variant of a standard product line, custom cabinet boxes for example, the decision depends on whether the cabinets that the cut center makes will work for you.

cut center has a huge selection

The cabinets that the Thermwood Cut Ready - Cut Center know how to make are built around the most common ways cabinets are made and offer a lot of flexibility. They may not be exactly what you currently make in every detail but they do offer the major features. In fact, they may include features that you can’t do today that make the product easier and better. For example, Cut Ready cabinets include assembly marks on major components. These are a dot pattern machined into mating parts that show you which parts fit together and in what orientation. They are completely hidden after assembly but save a ton of time when assembling more complex pieces. They also include drawer alignment holes machined into the cabinet sides. Put alignment pins in these holes and use them to install drawer slides and drawers for quick installation and virtually perfectly alignment the first time.

While you can program exactly what you want with a CNC router, no cabinet shop could possibly invest the programming time and effort needed to duplicate even a small portion of the products a cut center can make. For example, considering all the variations, the initial Cut Ready – Cut Center can make something approaching 20,000 different cabinet configurations without counting size variations.

Another consideration is that cut centers include things you may not make today, such as drawers, doors or moldings. It may be a lot less expensive to make these things yourself as long as they are already in the machine and you don’t have to spend a lot of time and effort learning and programming them. Most shops with a CNC router will not go through the trouble to figure all this out but, with a cut center, they are just sitting there and all you have to do is say “make it”.

financial comparisons

Now let’s look at finances. How does the cost of these two approaches compare?

The initial cost of a ready-to-run cut center is more than the cost of a conventional CNC router. Remember however, cut centers come complete with everything, including tooling. There are no options. CNC routers tend to have a lot of options and their selection depends on what you want to do with the machine. In addition, for a true comparison you must realize they are not exactly the same thing. For a true comparison, you must add to the CNC router and option cost, all the additional costs needed to get to the same point as a cut center, that is, a system ready to run production.

You need to consider the cost of a design software package and a computer system capable of running it plus the time and cost needed to learn and operate both of them. You must also consider the cost of travel and training for both the design software and machine, including the cost of the folks being trained and any resulting disruption this might cause. Cut centers do not require in-depth technical training, so the basics needed to run them can be taught rather quickly during installation. In fact, most folks can walk up to the machine and run it with no previous instruction.

When looking at a CNC router, you also need to consider the time required to develop and test all required product programs, including the time and material needed to proof the new designs. In most cases, although the initial cost seems to be higher, you will find that a cut center may actually be somewhat less expensive than a CNC router when both are programmed and ready for production. After all that, realize that a cut center can be leased for about the same cost per hour as a single employee.

Another way to look at it is that you can lease a cut center for less than the cost of a programmer for a CNC router and after five years, lease payments for the cut center go away while the cost for the programmer probably went up.

One other factor to consider is that with both systems ready to run, the CNC router will likely have been programmed for only the basic products you make while the cut center can make a variety of additional products such as closet cabinets, utility cabinets, bath cabinets, furniture, MDF doors, dovetail drawer boxes, profile and carved moldings. This is so easy that many shops will elect to include these additional products in their product offering so cut centers could generate more business and profit with little extra effort. With the cut center, its ability to make different productws will continue to grow as Thermwood continues to develop additions. You can download these for free. With a CNC router, you cannot program additional products for free.

the bottom line

So, there it is. Two approaches with the same goal. For truly custom products and the maximum flexibility in a technically savvy environment, the CNC router is probably better. For customized standard products in a less technical environment the cut center wins out. Which is better for you? Only you can decide.

more info

For more info on the Thermwood Cut Center, please visit cutready.com. For more info on our line of 3 and 5 axis CNC routers, please visit us at thermwood.com.

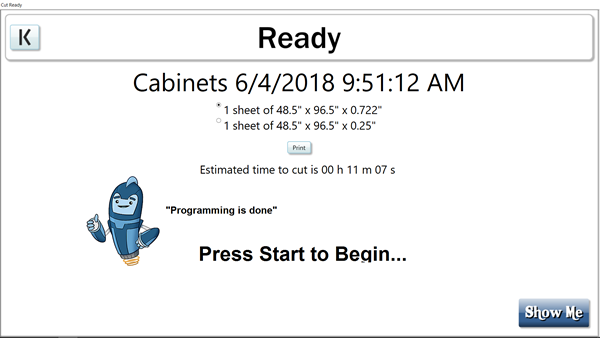

Cut Ready doesn’t need a programmer because there is already one inside the control. We call him “Artie”.

Cut Ready doesn’t need a programmer because there is already one inside the control. We call him “Artie”.

With the introduction of Thermwood’s “

With the introduction of Thermwood’s “ Now, there is a way for them to automate without any of that. It’s a different kind of machine called a “

Now, there is a way for them to automate without any of that. It’s a different kind of machine called a “