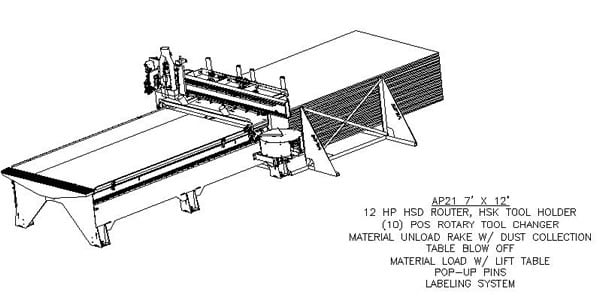

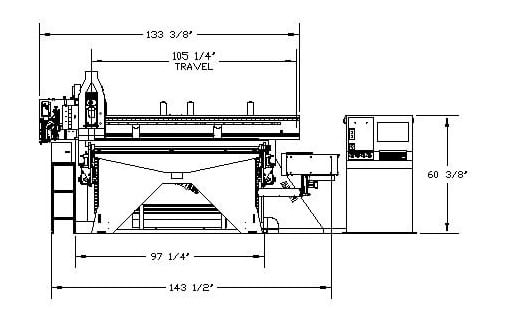

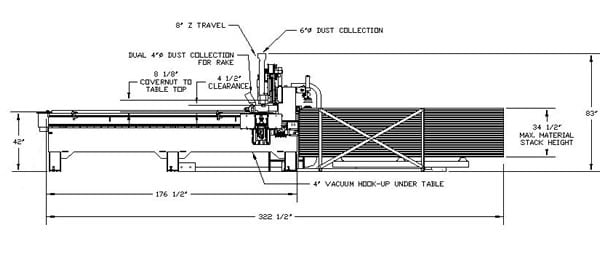

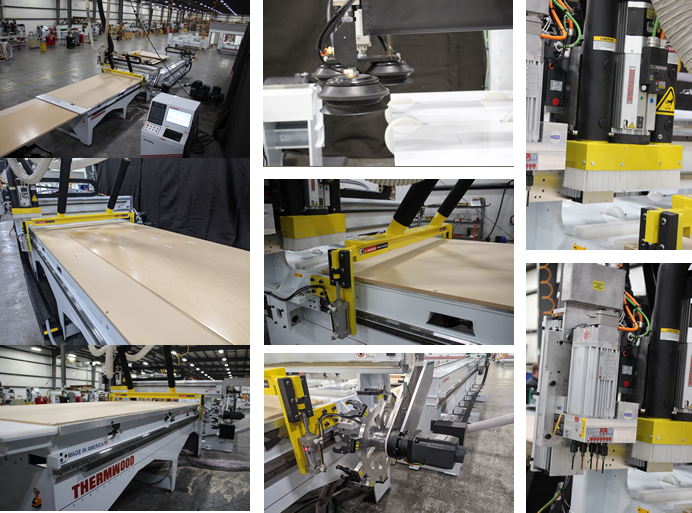

This all-new system is an advanced, fully-integrated nested-based CNC work cell designed to meet the needs of custom cabinet, closet and furniture builders. This complete solution includes an automatic off-load conveyor and a manual assist load system, ideal for producing custom cabinet and closet boxes, drawer boxes, doors and drawer fronts.

|

|

|

What Makes It Special: Learn More

Manual Lift Assist System:

Remote Operator Station:

Heavy-Duty Spindle & Tool Changer:

Machining & Off-loading Process:

Ultra 6 SuperControl:

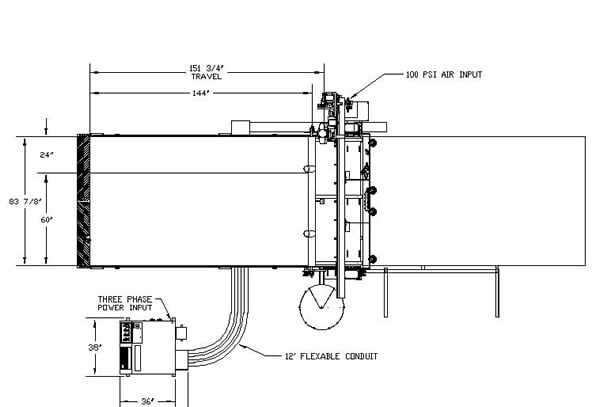

The CabinetShop 43-512-10 CNC Work Cell is engineered to optimize productivity, precision, and ease of use, making it an essential asset for custom cabinet and furniture manufacturing. CabinetShop 43 512-10 Nested Based Work Cell |

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible