Companies have been choosing Thermwood’s LSAM large scale additive manufacturing systems for their thermoplastic composite large part production. In a newly released video, Scott Vaal, Thermwood’s LSAM Product Manager, addresses the question of "Why LSAM?"

He addresses key aspects of the large scale additive manufacturing market and LSAM’s position in it. This video also addresses the current state of the art in additive print technology, offers a quick overview of the broad LSAM product line, slicing software, industry collaboration, additive system reliability, service, support, upgrade ability, plus other issues important to potential users and anyone interested in large scale additive manufacturing of thermoplastic composites.

Thermwood has found that many companies exploring large scale additive manufacturing don’t have a clear understanding of the current state of the market, the available technology or the capabilities of systems currently available. This video is intended to add a level of understanding, comfort and confidence that capable, proven and reliable large scale additive systems are not only available, but are already successfully operating in major industries every day, generating significant benefits and profits.

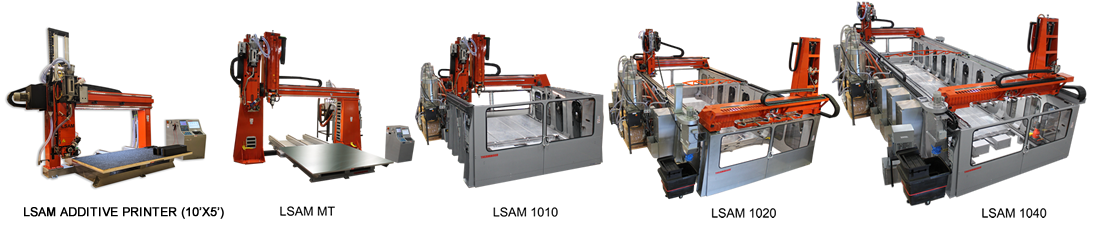

Largest Selection of Large Scale Additive Manufacturing Systems

With the introduction of the smaller LSAM Additive Printers plus these new wide table flagship LSAMs, Thermwood’s large scale additive manufacturing product line is, by far, the broadest available anywhere, with LSAM models from 5x5 foot to these new fifteen foot wide flagship models.