Today's smartphones are essentially handheld computers that also make phone calls. The speed of technological advancement in this area has been nothing short of phenomenal over the past decade. Not so with CNC routers. There has been the occasional improvement here and there, but not until recently with the introduction of the modern smart-router, has a CNC router come along that does much more than just route parts.

A modern smart-router saves material and labor and is really easy to use. The intial cost may be a little bit more than a traditional "dumb" router, but the benefits make it an overall much better investment for nested-based manufacturing.

Over the next several postings, we are going to demonstrate some of the ways that modern smart-routers can improve your production process and help you save money:

Pause button allows machine operator to safely do other jobs

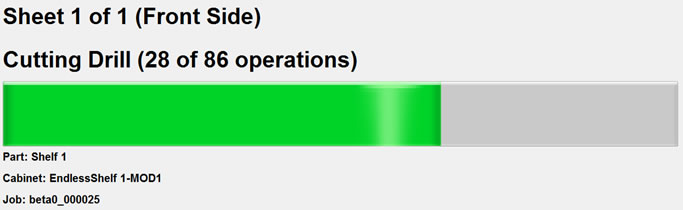

With standard routers, the operator must remain close to the control so he can stop the machine if something goes wrong. The only job he can really do is watch the machine. With a smart-router, a pause button clips to his belt. Pressing it anywhere in the production cell stops the machine. It works like an emergency stop, but is not a “wrench in the gearbox” emergency stop. It immediately stops the machine, but offers options. With this feature, the operator is free to perform other tasks away from the control. A progress bar, visible from a distance, shows the operator how long before he needs to service the machine. It’s like getting an extra worker for free. More info on this feature.

With standard routers, the operator must remain close to the control so he can stop the machine if something goes wrong. The only job he can really do is watch the machine. With a smart-router, a pause button clips to his belt. Pressing it anywhere in the production cell stops the machine. It works like an emergency stop, but is not a “wrench in the gearbox” emergency stop. It immediately stops the machine, but offers options. With this feature, the operator is free to perform other tasks away from the control. A progress bar, visible from a distance, shows the operator how long before he needs to service the machine. It’s like getting an extra worker for free. More info on this feature.

Smart-routers can recover from broken tools without scrapping the material

One great feature of a smart-router is the ability to recover from a broken tool without scrapping the sheet you are cutting or restarting the job. This can save a lot of time, effort and money.

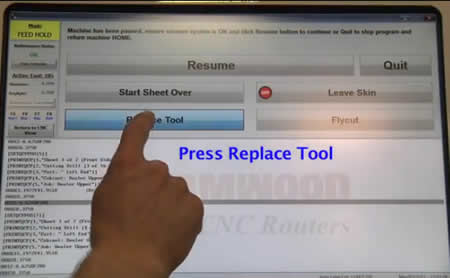

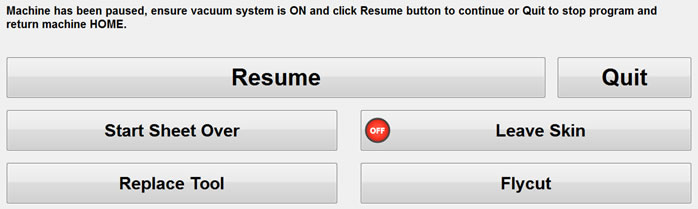

If a tool breaks, press the Pause button to stop the machine. Then select the Replace Tool option on the control, and the smart-router drops off the tool holder and notifies you to replace the tool. The machine then picks up the new tool, automatically measures it, adjusts the program for the new tool length, recuts the path of the broken tool and continues with the job. More information on this feature.