Thermwood has completed initial testing of a larger melt core for its LSAM (Large Scale Additive Manufacturing) systems and the results are stunning.

Print up to 570 pounds per hour

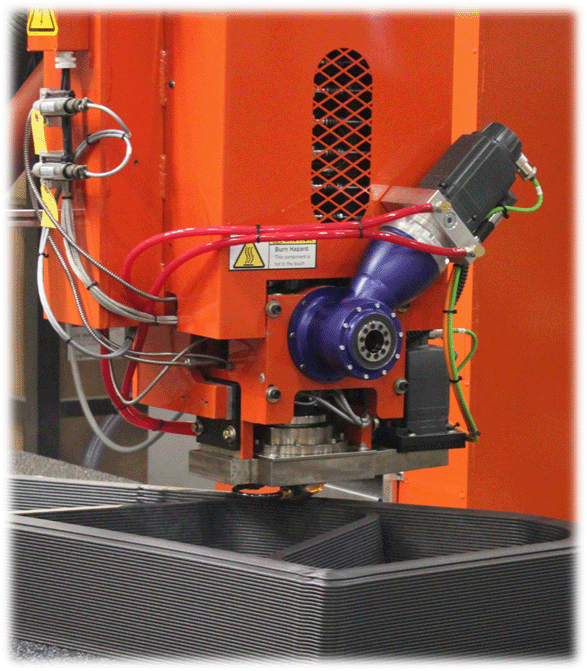

Thermwood’s additive print head housing can accommodate interchangeable melt cores. A melt core consists of a feed housing, extruder and polymer melt pump and determines just how fast material can be printed.

The standard 40mm melt core has a maximum output of between 190 and 210 pounds per hour, depending on the polymer being printed, which translates to 40 - 50 feet of standard bead (0.83”x0.20”) per minute.

The new 60mm melt core has been tested with different polymers and has achieved print rates from 480 to 570 pounds per hour, which translates to well over 100 feet of bead per minute.

More Info

With Thermwood’s room temperature “Continuous Cooling” print process, the cycle time for each layer is determined solely by how long it takes a particular printed polymer to cool to the proper temperature to accept the next layer.

Only by printing when the previously printed layer is within the proper temperature range can you achieve a completely solid, void free printed structure that maintains vacuum in an autoclave without a secondary coating. This is as fast as you can print a layer.

The print head output then determines how much material can be printed during the time it takes for the layer to cool. Bigger print heads mean bigger parts not faster layer to layer print time.

“This new development opens a new world of additive manufacturing possibilities” says Thermwood’s Founder, Chairman and CEO, Ken Susnjara. “This is one of the most exciting advances we have achieved to date and now we can do things we couldn’t even consider before”.

New Possibilities

For example, Thermwood recently announced Vertical Layer Printing which allows parts to be printed that are as long as the machine table. In this process, however, the layer stack direction is along the length of the part. This works well for room temperature or low temperature patterns, fixtures and molds, however, for high temperature molds, for use in an autoclave for example, the thermal expansion (CTE) along the stack direction is as much as 20 times greater than along the bead direction. Therefore, it is desirable to print long tools with the bead oriented in the long direction, however, print heads, even Thermwood’s 200 pound per hour head, currently the largest in the industry, have been too slow for this…until now.

The high print rate of the new melt core, even when processing high temperature materials, allows the print bead to be oriented along the length of the tool, even for tools that are as long as the machine table itself.

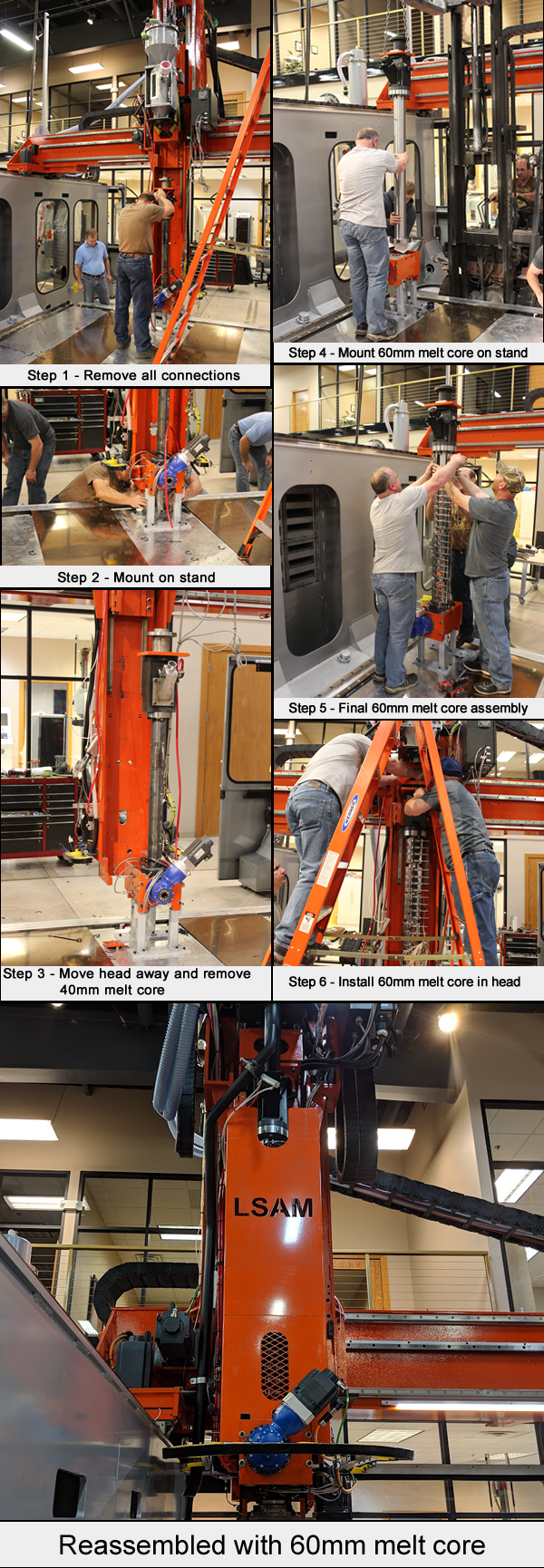

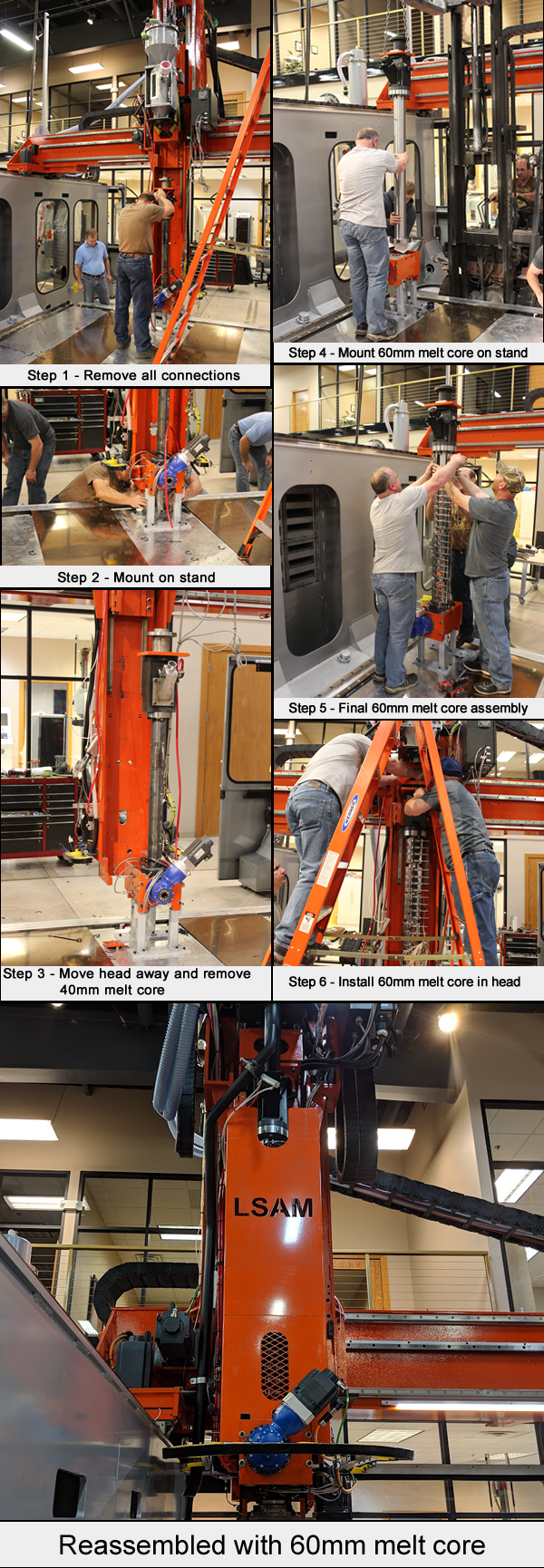

Melt Core Changeover in One Shift

In addition to a maximum speed, each melt core has a minimum speed at which it can continuously print. Parts with bead lengths smaller than this minimum, require the print head to move to a “Hot Hold” area where it runs at a slow maintenance speed, spilling material at a slow rate until the required cooling time has been achieved. This wastes material and means the larger melt core may not be desirable for all applications. Many tools and molds are just too small for efficient printing with the larger core.

If a user needs both small and large parts on the same machine, the melt cores can be switched in less than a shift.

Final Thoughts

Thermwood believes the next step in this development is to address the challenge of really long autoclave capable tooling. Be assured, work in this area has already begun.

More Information on LSAM

LSAM is based on exciting new technology developed from an entirely new direction.

LSAM is intended for industrial production. It is not a lab, evaluation or demonstration machine, but is instead a full-fledged industrial additive manufacturing system intended for the production of large scale components.

Much of the technology used in Thermwood’s LSAM machines and print process is completely new. Thermwood has already received numerous patents on these revolutionary developments and many more are in the works. In addition to the projects already announced, many other exciting results that LSAM has already achieved are covered by non-disclosure agreements and must be kept secret. LSAM is truly state-of-the-art in the exciting new world of large scale additive manufacturing.