This is part three in our blog series demonstrating some of the ways that modern smart-routers can make your job easier as well as help save you money.

Here, we focus on a couple of ways a smart-router can improve your nested-based production process:

-

Allowing you to easily use material left from a previous job

-

Guiding you with step-by-step instructions

Smart-routers easily use material left from a previous job

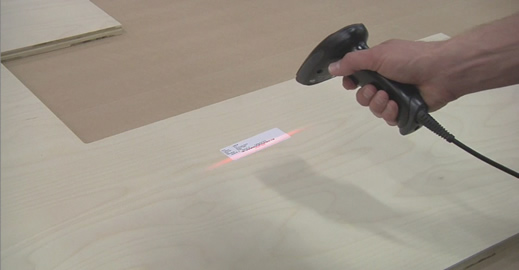

Replacing bad or scrap parts is really easy with a smart-router. At the end of a job, simply scan the labels of any parts you want to recut and the machine nests them on any material still on the table so you can recut them. This saves a lot over having to create new CNC programs to make replacement parts.

Replacing bad or scrap parts is really easy with a smart-router. At the end of a job, simply scan the labels of any parts you want to recut and the machine nests them on any material still on the table so you can recut them. This saves a lot over having to create new CNC programs to make replacement parts.

With a smart-router you can even add parts from previous jobs to a new job, provided you are running the same material (it monitors that for you). When replacement parts from another job are cut, a red bar on the label lets you know this part is for a different job.

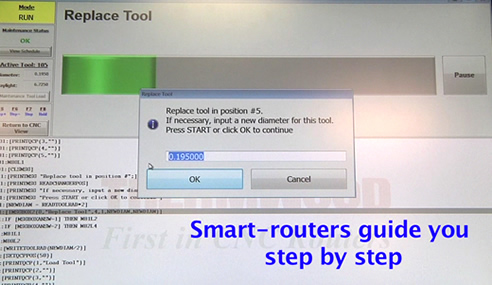

Smart-routers guide you step by step through the program

During program operation, smart-routers tell you what they are doing and offer instructions every step of the way. They tell you how many steps are in the program,what step they are on and what step is coming up next.

During program operation, smart-routers tell you what they are doing and offer instructions every step of the way. They tell you how many steps are in the program,what step they are on and what step is coming up next.

If you can read you can run a smart-router.