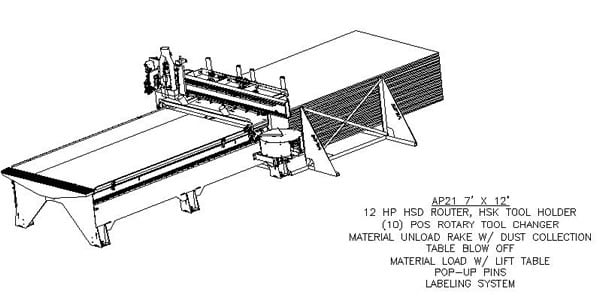

The Thermwood AutoProcessor is a high-speed, automatic load/unload, heavy-duty three-axis CNC routing system for nested based feed through machining. Available in a variety of machine table sizes, it is used in nested based production of cabinets, closets and custom furniture.

How it Works:

With each cycle, the machine simultaneously labels one sheet while positioning and machining the other sheet. It then off-loads the finished parts while loading the next sheet and repeats the process. Dust collection during this process keeps scrap and debris to a minimum.Labels help the operator to quickly sort the parts, and Assembly Marks help final assembly happen quickly and easily.

Thermwood AutoProcessor 5'x10' in a Customer's Shop:

Features of the Thermwood AutoProcessor:

- Various Table Sizes Available (5'x10', 5'x12' and 7''x12')

- Automatic Load/Unload System (6000 lb automatic lift table for loading and a steel offload/work table)

- 12HP (3,000-24,000 RPM) Spindle

- Universal Vacuum

- Rake w/Integrated Dust Collection

- Rapid Speed: 4100 Inches per minute

- Siemens Intelligent Servo Drives

- 3D Laser Compensated Axis Alignment

- 10 Position Rotary Automatic Changer

- Automatic Pop-Up Pins

- Automatic Tool Length Sensor

- Automatic Labeling System

- QCore SuperControl

- Machine Training and Installation

- Free Lifetime Phone/Forum Support

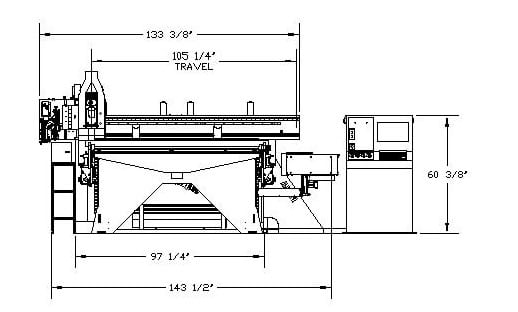

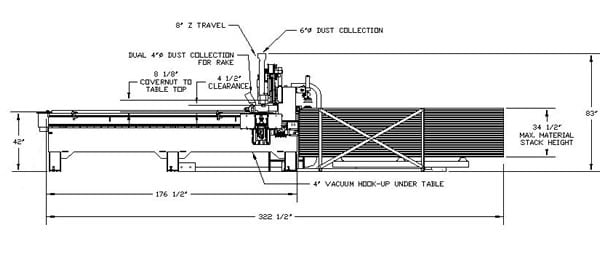

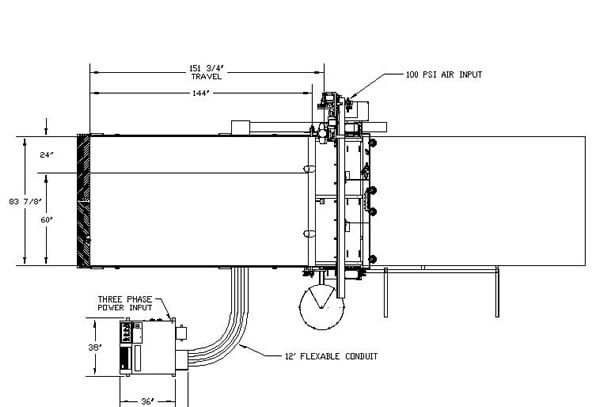

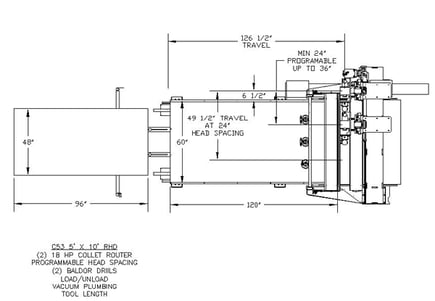

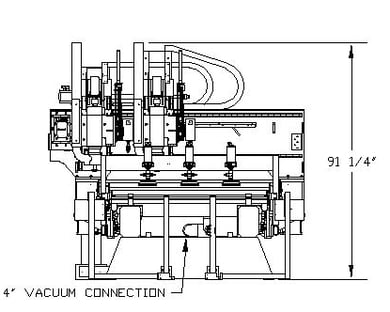

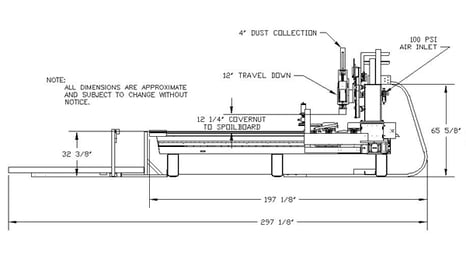

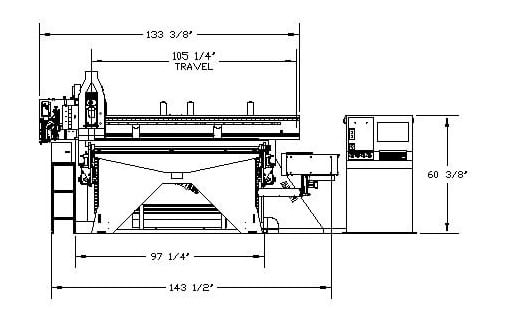

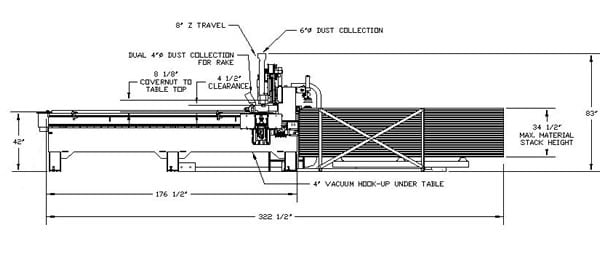

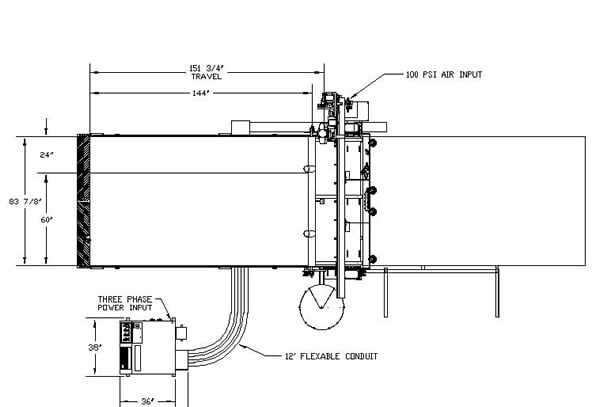

Drawings: