Can I Afford a Thermwood Cut Center?

“I’ll buy a CNC router as soon as I can afford it”. Is this something you’ve said to yourself time and time again over the years? Surveys indicate that 50% to 70% of cabinet shops say this, depending on which survey you read. A CNC router is automation, it is productivity and it is on every cabinetmakers short list of things they would really, really like to have. So exactly when can you afford a CNC router?

The simple answer is that you can afford it when it will make you more than it costs. Taking a look at the Thermwood Cut Center, for instance, the Cut Center may have a slightly higher than average purchase price, but the immediate benefits and ability to get into production quickly can outweigh any initial costs.

The Cut Center is Different in a Good Way

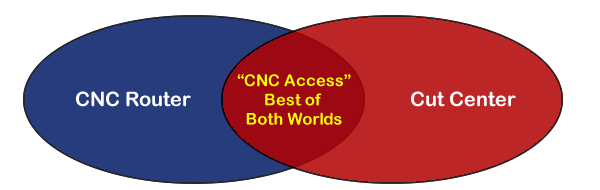

The Cut Center is not like any regular CNC router you may be familiar with. It doesn’t require you to learn complex programming to operate, and is so user-friendly that it walks you through every step of the process when making cabinets, closets, furniture, doors, drawers and much more. You simply tell the machine what you want to make via an easy to use touch screen interface, and it does it. No programming is required.

The Cut Center is not like any regular CNC router you may be familiar with. It doesn’t require you to learn complex programming to operate, and is so user-friendly that it walks you through every step of the process when making cabinets, closets, furniture, doors, drawers and much more. You simply tell the machine what you want to make via an easy to use touch screen interface, and it does it. No programming is required.

"No Programming" is a Huge Factor

That little bit about “no programming” is huge factor – no matter how great of a deal you get on the purchase of a CNC router, it will still need to be programmed. This means that you either need to learn to program yourself or you’ll need to hire a CNC programmer.

A typical CNC programmer will cost you more each month than the payment on a Thermwood Cut Center. And every few years, that programmer will most likely cost more money, while the payments on a Cut Center will go away once the machine is paid off.

How About Programming it Myself?

Programming it yourself is possible, but it isn’t simple. CNC routers require a constant stream of programs to run. Solving problems (like damaged or scrapped parts or defects in material) means even more CNC programs. Programming custom cabinets on a CNC router is a full time job….good thing you have nothing else to do!

No Software Required

And don’t forget about the software to run the CNC router. Cheap cabinet software is limited and difficult. It will most likely take more time to learn and operate, which means more money. Really good software can cost as much, or more than a cheap CNC router, and then you still need to learn to use it.

Save By Using Scrap Material

Another consideration is scrap material. You will most likely have one or more partial sheets left from each job. Regardless of what they tell you, it is so difficult, complex and expensive to add this to new jobs that virtually everyone just throws it away. With the Cut Center, you just scan the label on any extra material lying around and it is added to the job, automatically. This can mean a lot of money saved at the end of the year.

Another consideration is scrap material. You will most likely have one or more partial sheets left from each job. Regardless of what they tell you, it is so difficult, complex and expensive to add this to new jobs that virtually everyone just throws it away. With the Cut Center, you just scan the label on any extra material lying around and it is added to the job, automatically. This can mean a lot of money saved at the end of the year.

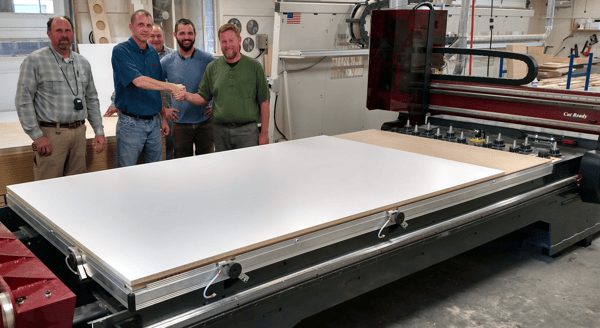

Get Into Production Quickly

With the typical Thermwood Cut Center installation, you can be in full production is a little as about half a day. A regular CNC router can take as much as six months to get to that point. A half a day or half a year? In business, time is money, and there is serious cost associated with that half a year.

Enhancing Employee Productivity

A new CNC router can sometimes be seen by employees as intimidating or threatening when it is installed into a shop. Your workers may either be worried that their jobs could be affected by this dazzling new piece of equipment, or that they will be required to learn an entirely new programming language or operating procedure. With the Thermwood Cut Center, there is no programming knowledge necessary. Basically anyone can walk up to the machine, pick out part(s), select their desired quantities/sizes and make it. The Cut Center is designed to be as simple as possible to operate, and to help shops and employees be more productive and efficient.

Another Way to Make Money with a Thermwood Cut Center

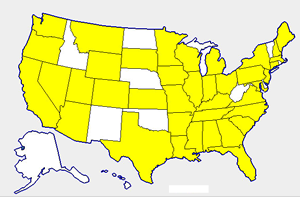

Finally, there is Production Sharing. This is a program where you sell production time on your machine by making parts for other shops that don’t have a Cut Center or CNC router. Thermwood provides an area on our web site where you can advertise your services (there is no cost for this), and you work directly with the other shops to set up your jobs. Thermwood receives no money for these transactions.

Finally, there is Production Sharing. This is a program where you sell production time on your machine by making parts for other shops that don’t have a Cut Center or CNC router. Thermwood provides an area on our web site where you can advertise your services (there is no cost for this), and you work directly with the other shops to set up your jobs. Thermwood receives no money for these transactions.

More about the Thermwood Cut Center:

Operate as a Cut Center with No Programming

With the award-winning Thermwood Cut Center, there are no computers or design software. Everything is already in the machine. There is no programming. The cut center doesn’t need a computer to tell it how to move because it already knows how to make cabinets. Just tell it what you want to make, and it does it - it is that simple!

With the award-winning Thermwood Cut Center, there are no computers or design software. Everything is already in the machine. There is no programming. The cut center doesn’t need a computer to tell it how to move because it already knows how to make cabinets. Just tell it what you want to make, and it does it - it is that simple!

Operate as a CNC Router

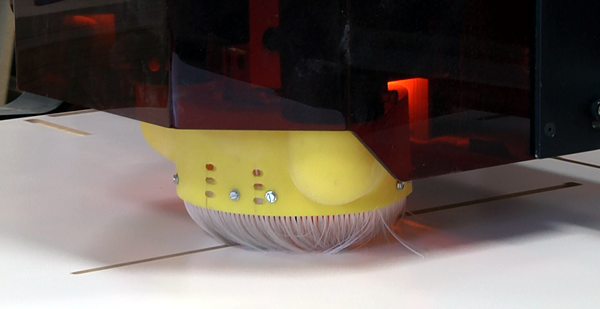

Also, you can operate the system as a CNC router in the traditional manner, running programs generated with virtually any CNC software. Thermwood has created a simple way to switch between operating as a CNC router and operating as a Cut Center to assure that all machine parameters are properly reset and that the standard Cut Center tooling is properly installed, checked and ready to run.

ermwood's

ermwood's

The Thermwood

The Thermwood