Posted by Duane Marrett on Wed, Jun 04, 2025

Tags: Additive, LSAM, Additive Manufacturing, VLP, High Temperature, ALP, HLP, LFAM, LSAM1540

Posted by Duane Marrett on Mon, Nov 04, 2024

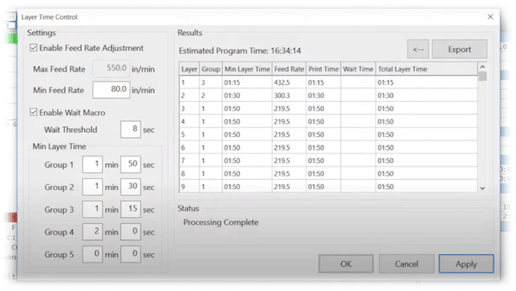

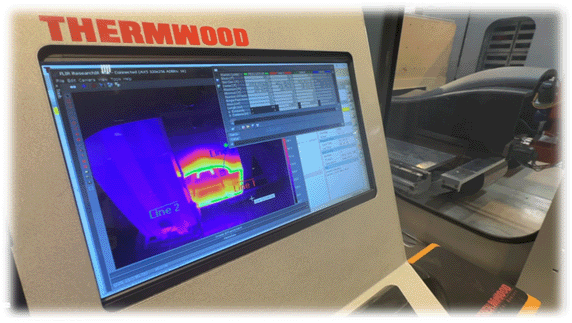

Tags: Additive, LSAM, Additive Manufacturing, Patented, LSAM 1020, High Temperature, LFAM, Features, High Temperature Material, Layer Time Control

Posted by Duane Marrett on Fri, Nov 01, 2024

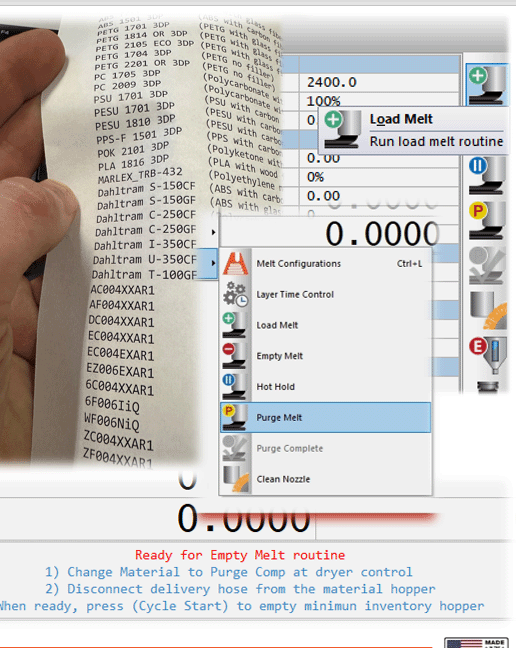

Tags: Additive, LSAM, Additive Manufacturing, Patented, LSAM 1020, High Temperature, LFAM, Features, High Temperature Material, Material Flexibility

Posted by Duane Marrett on Thu, Oct 31, 2024

Tags: substrates, Additive, LSAM, Additive Manufacturing, Patented, LSAM 1020, High Temperature, LFAM, Features, Bead Board

Posted by Duane Marrett on Wed, Oct 30, 2024

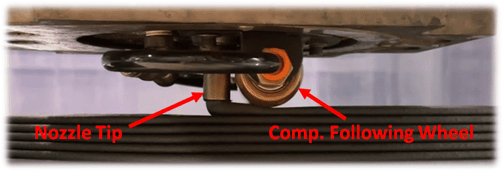

Tags: Additive, LSAM, Additive Manufacturing, Patented, LSAM 1020, High Temperature, Compression Wheel, LFAM, Features

Posted by Duane Marrett on Tue, Oct 29, 2024

Tags: Additive, LSAM, Additive Manufacturing, Patented, Melt Core, LSAM 1020, High Temperature, LFAM, Features

Thermwood has been pioneering Large Format Additive Manufacturing (LFAM) since 2016, leading the industry with our advanced LSAM systems. These machines offer more than just large-scale capabilities—they deliver an unmatched printing experience with superior print consistency, precise temperature control, and powerful slicing software.

In this series, we’ll take you through the exclusive benefits of LSAM technology, starting with our patented Melt Core System. Discover how this cutting-edge innovation redefines material processing to achieve faster, more reliable, and efficient large-scale 3D printing. Ready to explore the future of manufacturing? Dive in and see why Thermwood is the leader in LFAM!

Posted by Duane Marrett on Fri, Oct 25, 2024

Tags: Demonstrations, Additive, LSAM, Additive Manufacturing, LSAM 1020, High Temperature, LFAM, ST Engineering

Posted by Duane Marrett on Fri, Oct 01, 2021

Tags: Thermwood, Announcements, Trade Shows, Large Scale, Thermwood LSAM, SABIC, LSAM Additive Printers, Airtech, High Temperature, Techmer PM, CAMX

Thermwood will be printing high temp autoclave aerospace tooling on an LSAM Additive Printer 510 LIVE at CAMX 2021 in Dallas, TX, October 19th-21st in Booth #M44B. LSAM Research Laboratory at Purdue ADDITIVE3D simulation software will be on display as well in adjacent Booth #M44, with Purdue representatives on site for demonstrations. We will be printing a different material each day, donated by AIRTECH, SABIC AND TECHMER PM. This promises to be an exciting demonstration of the LSAM Additive Printer Large Scale Additive System!

Click the link below to Be Our Guest and register for a Free CAMX Exhibit pass and 15% off the Conference Registration Fee.

Free Exhibit Hall Pass Code: FREEEX021

15% off Full Conference Registration Code: FREEFULL21

Make plans now to visit the Kay Bailey Hutchinson Convention Center and stop by Thermwood Booth #M44B to witness this live and in-person!

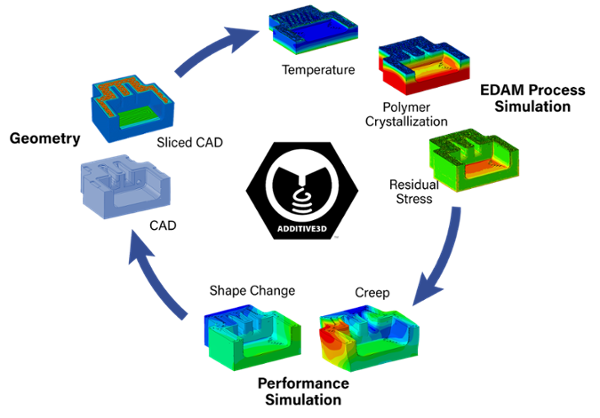

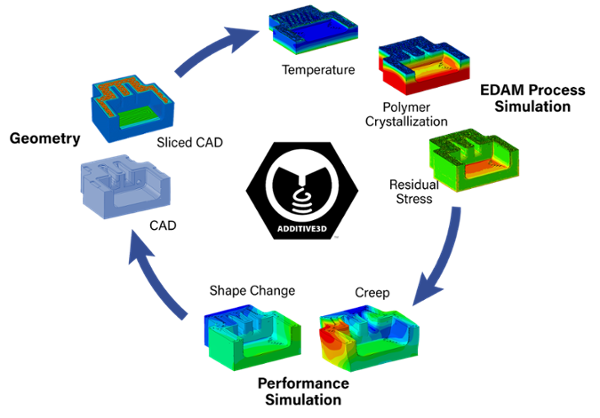

Representatives from the recently announced Thermwood Research Laboratory at Purdue University (located in Purdue University's Composites Manufacturing Simulation Center - CSMC) will also be on hand to demonstrate their ADDITVE3D simulation software.

On Tuesday, October 19th, we will be printing AIRTECH PEI DALTRAM I-350CF

On Wednesday, October 20th we will be printing SABIC LNP™ THERMOCOMP™ AM EC004XXAR1 ULTEM compound.

On Thursday, October 21st, we will be printing TECHMERPM PESU 1810 3DP.

Posted by Duane Marrett on Thu, Sep 02, 2021

Tags: Thermwood, Announcements, Trade Shows, Large Scale, Thermwood LSAM, SABIC, LSAM Additive Printers, RAPID + TCT, Airtech, High Temperature, Techmer PM

Thermwood will be printing high temp autoclave aerospace tooling on an LSAM Additive Printer 510 LIVE at RAPID + TCT 2021 in Chicago, IL September 13th-15th. LSAM Research Laboratory at Purdue ADDITIVE3D Software will be on display as well, with Purdue representatives on site for demonstrations. We will be printing a different material each day, donated by SABIC, TECHMER PM and AIRTECH. This promises to be an exciting demonstration of the LSAM Additive Printer Large Scale Additive System.

Click the link below to Be Our Guest and register for a Free Rapid + TCT Expo pass and $100 off the Conference Registration Fee.

Use Promo Code: 10016220

Make plans now to visit the McCormick Center and stop by Thermwood booth #E7628 to witness this live and in-person!

Representatives from the recently announced Thermwood Research Laboratory at Purdue University (located in Purdue University's Composites Manufacturing Simulation Center - CSMC) will also be on hand to demonstrate their ADDITVE3D simulation software.

On Monday, September 13th we will be printing SABIC LNP™ THERMOCOMP™ AM EC004XXAR1 ULTEM compound.

On Tuesday, September 14th, we will be printing TECHMERPM PESU 1810 3DP.

On Wednesday, September 15th, we will be printing AIRTECH PEI DALTRAM I-350CF

© Thermwood Corporation. All Rights Reserved