Most people looking at a router for the first time do not realize that the vast majority of their cost will not be in running the router, but actually in EVERYTHING ELSE required to run the router (preparation, programming, hold down, operating procedures and error handling are the main cost areas).

Most people looking at a router for the first time do not realize that the vast majority of their cost will not be in running the router, but actually in EVERYTHING ELSE required to run the router (preparation, programming, hold down, operating procedures and error handling are the main cost areas).

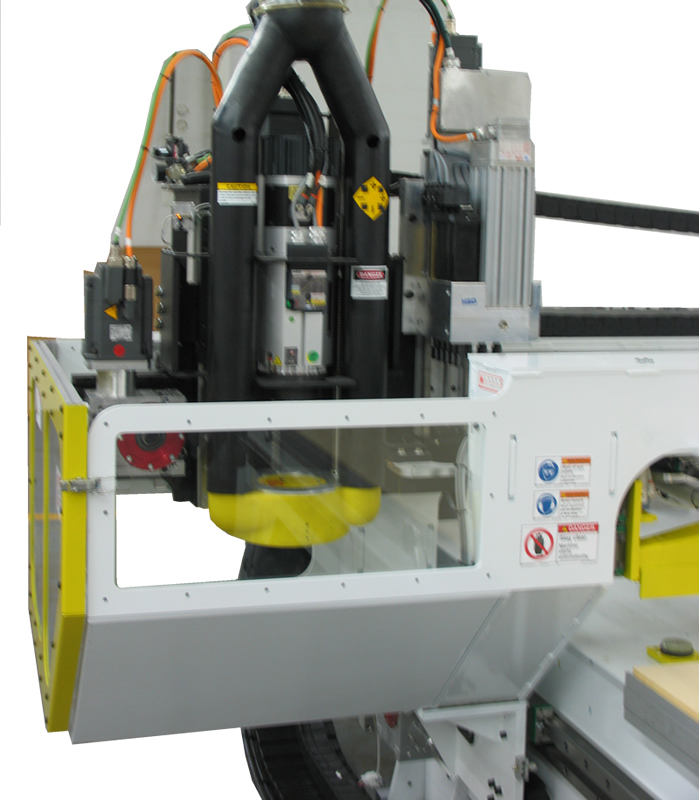

Ordinary routers do not focus on these areas. They simply rely on the user to take care of them and usually it is not that easy. Thermwood smart routers address these areas in a big way. They focus on the areas where you spend the most money because that’s where you can make the most money.

Just like a smart phone does more than simply make phone calls, a Thermwood smart router does much more than just route parts. The “more” in a smart router saves material and labor and makes it very easy to use. A smart router may cost a bit more, but is substantially more profitable, making it a much better overall investment.

Thermwood Smart Router Advantages:

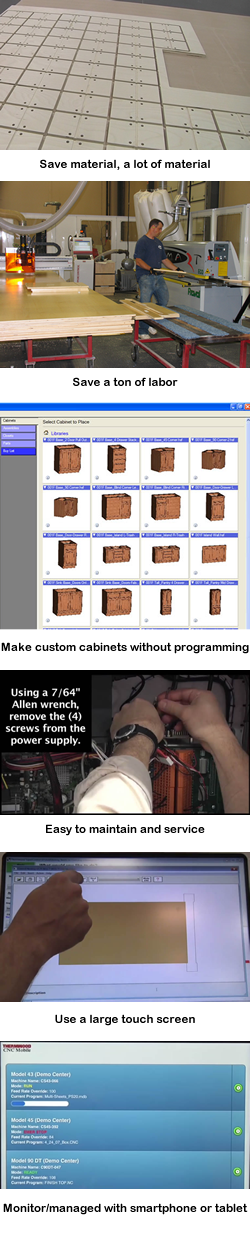

Smart Routers Save Material

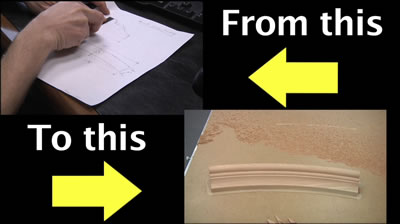

Easily use material left from the last job

Easily use material left from the last job- Recover from broken tools without scrapping material

- Smart nesting keeps smaller parts from moving and being scrapped

- Nest around defects to use damaged or flawed material

- Save the sheet if parts start moving

- Warns you if spoilboard needs resurfacing

- Fly cut spoilboard in the middle of a job

- Machine back operations on the full sheet

- Alerts you when running critical parts

Smart Routers Save Labor

- Smart routers are easier to program

- Recut parts without programming

- Easily recover from problems without programming

- Run at the machine without programming each job

- During file selection, images help avoid errors

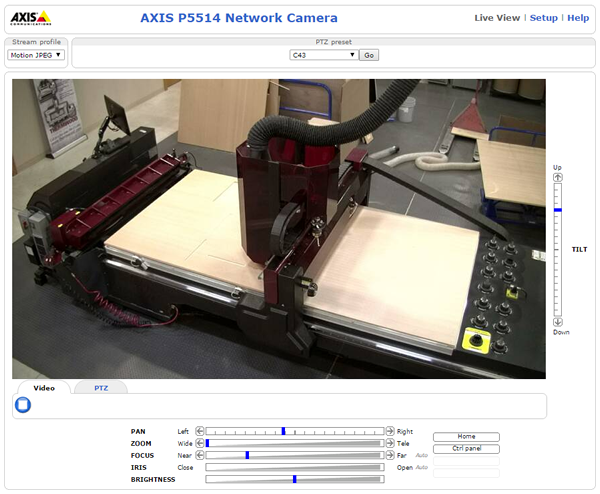

- Machine operator can safely do other jobs

- Avoid processing parts one at a time

Smart Routers are Easy to Use

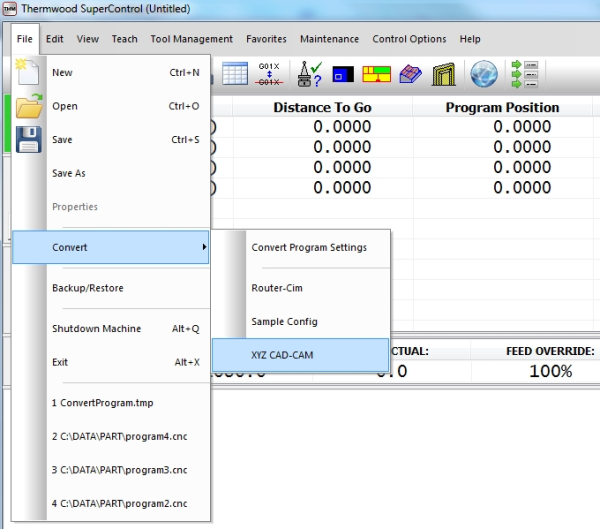

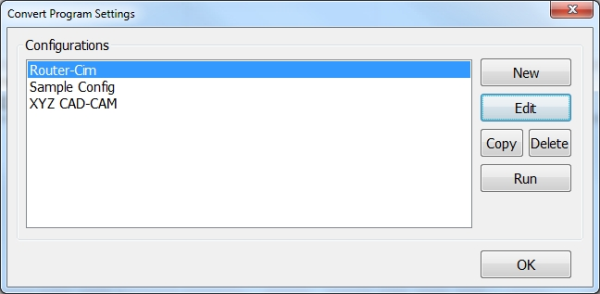

- Run from virtually any software or any program

- The same file works on any smart router regardless of size or configuration

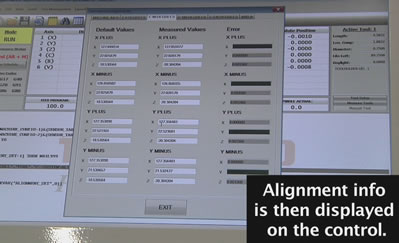

- Smart routers easily process material whose thickness varies from sheet to sheet

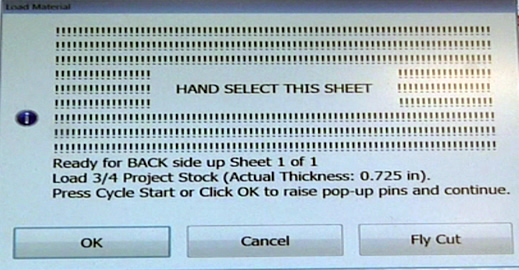

- Smart routers guide you step by step

- Uses smart labels to make parts easy to sort

- Assembly marks make parts easy to assemble

- Smart tooling avoids tooling errors

- Smart routers manage tooling for you

- Smart routers machine a profile edge without a profile tool

Smart Routers are Easy to Maintain and Service

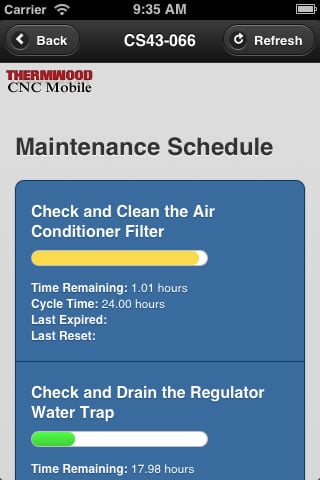

- Automatically manages routine maintenance

- Helps you recover from errors quickly and easily

- Maintenance and operating manuals are right on the screen

- Watch how-to videos for service

- 3D CAD drawings identify every part quickly and easily

- Smart routers can be serviced over the internet

- Smart routers are updated online

Other Differences

- Smart routers are not limited by memory

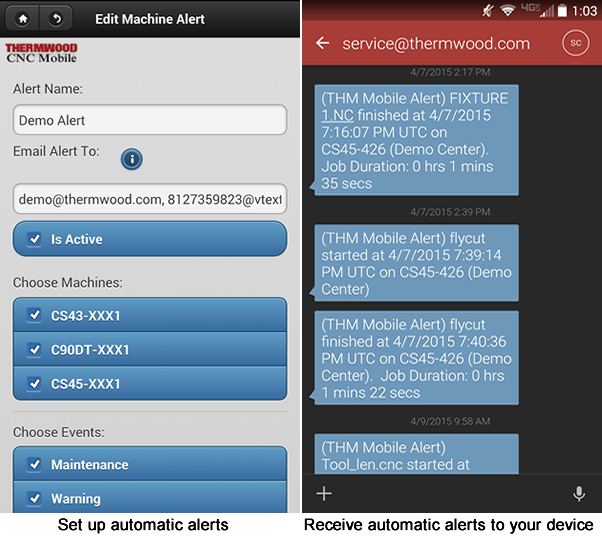

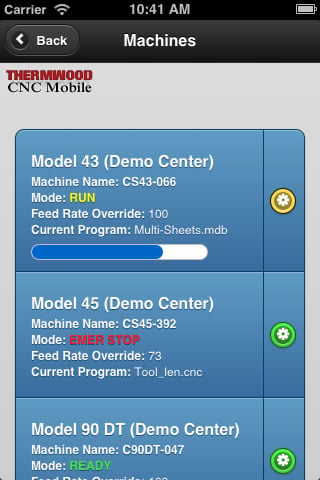

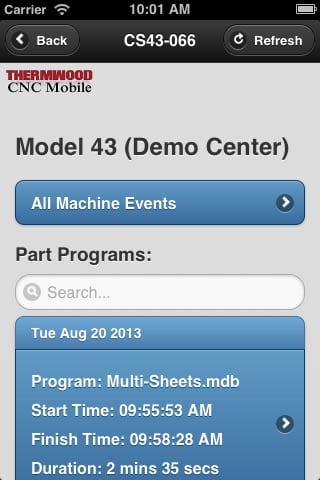

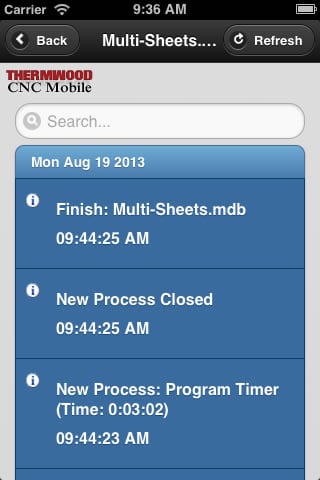

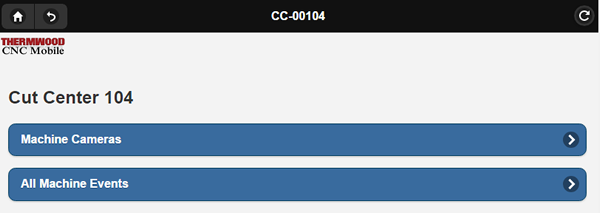

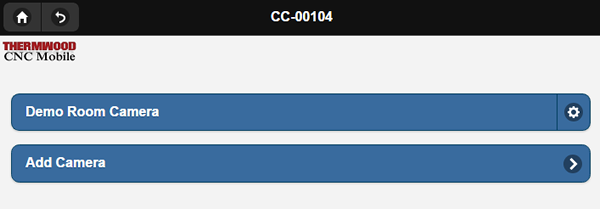

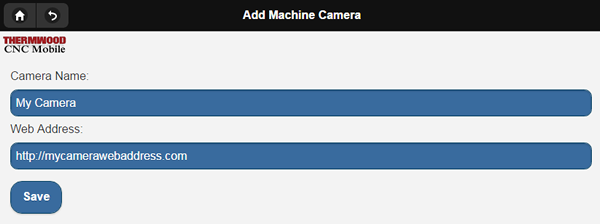

- Smart routers can be monitored and managed with your smartphone or tablet

- Smart routers use a large touch screen like other modern devices

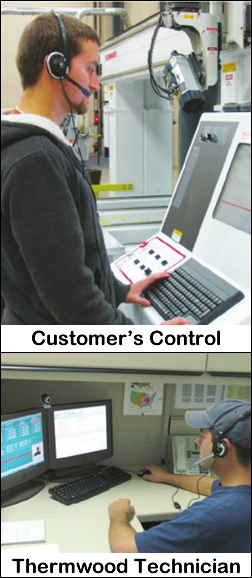

Virtual Service is a "one way service" which can only be initiated from the customer's control. The customer simply selects the "Connect to Virtual Service" button on their control, and within a short period of time, they are connected to a Thermwood service technician and can interact via voice, chat and webcam.

Virtual Service is a "one way service" which can only be initiated from the customer's control. The customer simply selects the "Connect to Virtual Service" button on their control, and within a short period of time, they are connected to a Thermwood service technician and can interact via voice, chat and webcam.

The

The

Smart-routers alert you when running critical or prominent parts. Certain parts are prominent on the final product, door and drawer fronts for example.

Smart-routers alert you when running critical or prominent parts. Certain parts are prominent on the final product, door and drawer fronts for example.

Features:

Features: