This is part four in our blog series demonstrating some of the ways that modern smart-routers can make your job easier as well as help save you money.

Here, we focus on a couple of ways a smart-router can improve your nested-based production process:

-

Allowing you to automatically flycut the spoilboard in the middle of a job

-

Smart-routers can be monitored and managed from your smartphone or tablet

Smart-routers easily flycut the spoilboard in the middle of a job

Maintaining a good working spoilboard surface with ordinary routers is involved and prone to problems. With a smart-router, this process is automated and easy. If you need to flycut the spoilboard in the middle of a job, just press the "Flycut" buttom on the control and the smart-router will automatically walk you through the steps. This can save a lot of hassle by allowing you to quickly level the surface of your spoilboard at any point in the job.

Smart-routers can be monitored from your mobile device

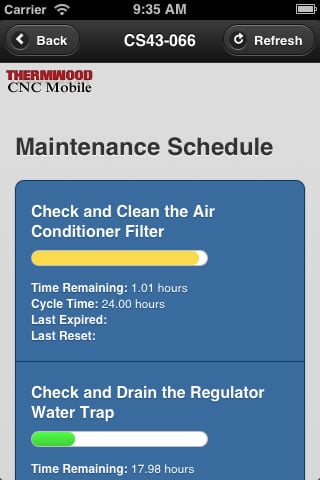

Smart-routers live on the web. They access updates on the web, are serviced through the web and let you monitor and manage your smart-router using your smart phone or tablet.

Smart-routers do this through the use of apps that allow users to monitor their CNC router(s) and the programs that run on them from anywhere. These apps permit users to obtain the following information and more:

-

A listing of every machine (includes an optional user customizable nickname)

-

The current state (ready, running or in e-stop)

-

The current Feed Override setting

-

The current program loaded and or running

-

A listing of all current and past part programs loaded/ran in chronological order with extensions

-

A listing of machine events during each part program in chronological order

-

A listing of the cycle time of every part program ran in chronological order

A listing of the cycle time of every part program ran in chronological order -

A listing of completion or interrupt times in each part program ran in chronological order

-

All machine events in chronological order with filtering

-

Monitor scheduled maintenance with a cycle time countdown as well as a graphical countdown progress bar

-

A time stamp listing of all previous maintenance performed

-

The ability to request a service phone call from a support technician right from your device.