Sneek Peak: Printing Process on a Thermwood LSAM 1020 for Naval Surface Warfare Center

Posted by Duane Marrett on Fri, Jul 12, 2024

Tags: Demonstrations, LSAM, Naval Surface Warfare, LSAM 1020

Thermwood Collaborating with the Navy to Explore Additive Manufacturing Technology

Posted by Duane Marrett on Wed, Nov 14, 2018

Tags: Thermwood, Announcements, 3D printing, Additive, LSAM, 3D Print, Thermwood LSAM, Navy, Additive Manufacturing, Submarine, Naval Surface Warfare

Thermwood Corporation has entered into a collaborative program with the Naval Surface Warfare Center, Carderock Division to explore the use of additive manufacturing technology in developing marine models for ship and ship systems testing.

Please click below for video

The Details

Carderock Division is the U.S. Navy's state-of-the-art research, engineering, modeling and test center for ships and ship systems. It is the largest, most comprehensive establishment of its kind in the world, serving a dual role in support of both our U.S. naval forces and the maritime industry.

Navy and maritime communities have come to depend on their expertise and innovative spirit in developing advanced platforms and systems, enhancing naval performance, reducing operating costs and addressing the Navy's evolving mission.

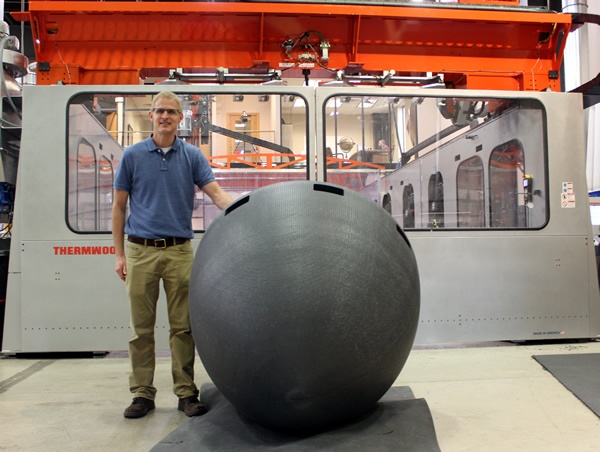

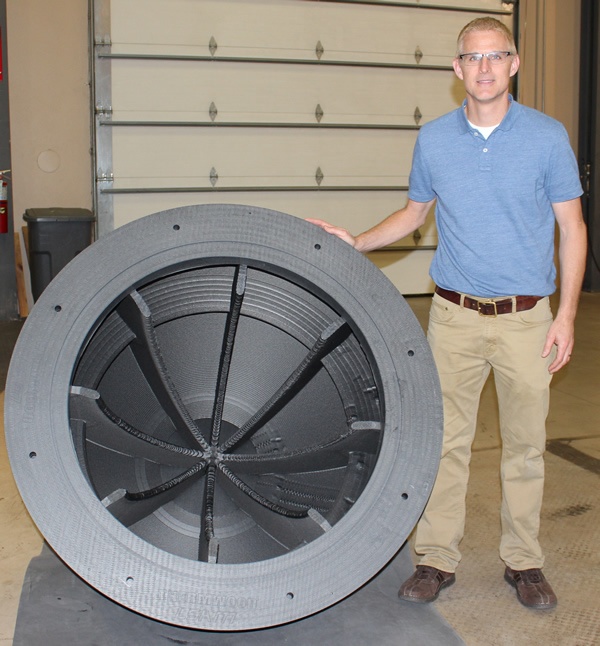

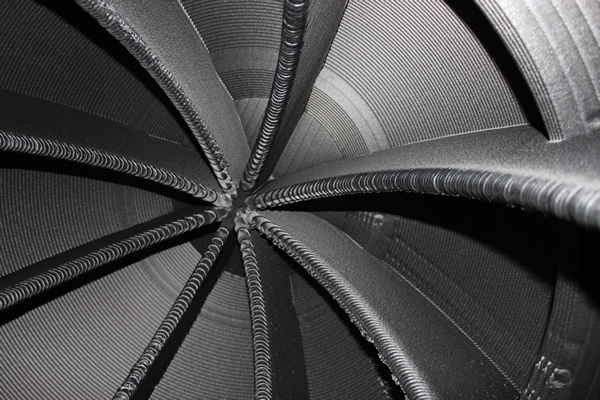

This initial validation program was centered on printing an unclassified scale nose of a submarine using Thermwood’s LSAM additive manufacturing system. The part was printed using 20% carbon fiber filled ABS in 11 hours and 45 minutes using traditional horizontal layer printing and a 40mm melt core. Final trim required 5 hours. Both printing and trimming were completed on the same machine, using Thermwood’s 10’ x 20’ LSAM at its demonstration lab in Southern Indiana.

Because of layer cooling requirements, the print rate for this part was less than half of the maximum rate the machine is capable of. It is expected that, moving forward, this program will include the printing of additional components using both horizontal and vertical layer printing.

More Information on LSAM

LSAM is based on exciting new technology developed from an entirely new direction.

LSAM is intended for industrial production. It is not a lab, evaluation or demonstration machine, but is instead a full-fledged industrial additive manufacturing system intended for the production of large scale components.

Much of the technology used in Thermwood's LSAM machines and print process is completely new. Thermwood has already received numerous patents on this revolutionary development and many more are in the works. Many exciting results that LSAM has already achieved are covered by non-disclosure agreements and must be kept secret. LSAM is truly state-of-the-art in the exciting new world of large scale additive manufacturing.

The Secret to LSAM Print Quality...A Different Process