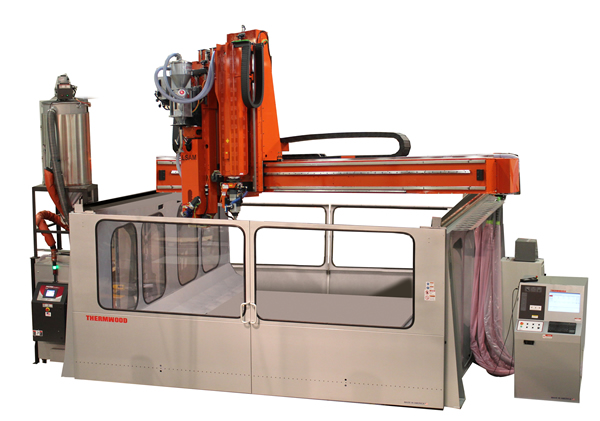

Thermwood has completed the first of a new type of additive print and trim system, the LSAM 1010. This is a fixed table, high wall system with both print and trim head mounted on a single gantry. Although with a ten foot by ten foot table, it is a bit smaller than the larger dual gantry flagship LSAM systems, it does require a significantly larger gantry.

The LSAM 1010 can both print and trim, but not at the same time. It uses the same 40mm print head that is standard on the larger LSAM systems and the same five axis trim head. It has the same 5 foot high print and trim capability of the larger machines. The addition of both of these on a single gantry adds two major new requirements.

Two Major New Requirements

First, the gantry must be significantly longer to accommodate the width of both heads, while also allowing both heads to cover the entire table.

Also, the gantry must be significantly stronger to rigidly support both the print and trim head, which together weigh well over 7,000 pounds, resulting in a live load (the parts of the machine that actually move) of over 18,000 pounds. Despite the weight, the machine can move at speeds up to almost three feet per second. This is not a small machine.

New M400 Helps Build Large Machines

The production of this new gantry has been made possible by the commissioning of Thermwood’s new M400 five axis metal working system which can machine parts up to 35 feet long. The gantry design uses Thermwood’s slot and tab construction method which produces engineered steel structures that are extremely strong and stiff.

More Details About the LSAM 1010

Since the LSAM 1010 has a fixed table, there is no practical part weight limitation.

The LSAM 1010 has the same 200 lb maximum print rate capability of the larger flagship LSAM systems but is still priced well under the LSAM 1020, which is the smallest dual gantry LSAM available.

The LSAM 1010 is also available as a “print only” machine for companies who already have the necessary machining capacity, bringing the price down even more.

The LSAM 1010 is ideal for companies whose size requirements fit the available envelope and where a sequential process production rate (print and then trim) is adequate. It is also ideal for companies who need relatively large, heavy parts but don’t need trim capability. The lower price point also makes the LSAM 1010 easier to cost justify for a wider variety of end applications.

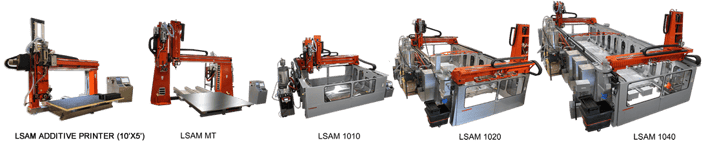

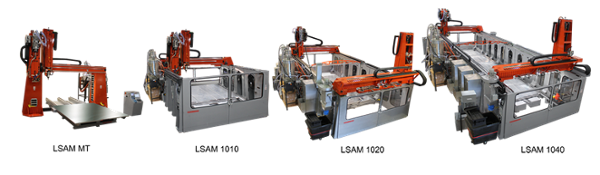

Largest Selection of Large Scale Additive Manufacturing Systems

The LSAM 1010 is part of the LSAM product line which offers the largest selection of large scale additive manufacturing systems available anywhere. There is a system available for about any large scale additive requirement from a 5x5 Additive (Print Only) Printer to giant, dual gantry, print and trim machines up to 40 foot long. Longer machines are available however, 40 foot are the longest machines produced to date.

Large Scale Additive Manufacturing Systems from the industry leader, LSAM by Thermwood.

Thermwood LSAM 2020 - Year in Review

Thermwood LSAM 2020 - Year in Review