Posted by Duane Marrett on Wed, Jun 04, 2025

Tags: Additive, LSAM, Additive Manufacturing, VLP, High Temperature, ALP, HLP, LFAM, LSAM1540

Posted by Duane Marrett on Tue, Apr 25, 2023

Tags: Thermwood, Video, Thermwood LSAM, VLP, LSAM AP, Fixture

Posted by Duane Marrett on Tue, Jan 18, 2022

Tags: Thermwood, Announcements, Thermwood LSAM, Patented, VLP, ALP, HLP, Compression Wheel

Virtually all, if not all, large format, FDM additive systems, sold to industry in the last several years have been Thermwood LSAMs.

Watch the video below to learn 21 reasons why:

Posted by Duane Marrett on Tue, Nov 30, 2021

Tags: Thermwood, Announcements, Thermwood LSAM, VLP, ALP

Thermwood has added a third print orientation to its LSAM Large Scale Additive Manufacturing systems.

LSAM systems currently can print both horizontal and vertical layers if equipped with the Vertical Layer Print (VLP) option, available on most Thermwood LSAM machines. This new addition adds Angle Layer Printing (ALP) to the VLP option. Angle Layer Printing is the ability to print at a 45 degree angle.

LSAM Angle Layer Printing (ALP) shown

LSAM Regular Vertical Layer Printing (VLP) shown

LSAM Horizontal Layer Printing (HLP) shown

Each print orientation has advantages and limitations for a particular part design. Offering all three on the same machine, for the first time, means maximum print flexibility. All print orientations use the complete LSAM print head including exclusive LSAM print features such as the patented compression wheel and Thermal Sensor Layer Automation.

This helps maintain an even layer temperature throughout the print. LSAM automatically adjusts the individual layer temperature to provide for superior layer fusion (as seen below).

LSAM machines are currently operating in regular daily industrial production with many existing systems already equipped with Vertical Layer Print capability. The Vertical Layer Print (VLP) option has been replaced with a VLP/ALP option on new machines which offers both vertical and angle layer print capability, in addition to the standard horizontal layer print.

Angle Layer Print (ALP) can be easily and inexpensively added to machines operating in the field that already have the VLP option.

If a machine was purchased without VLP, the entire new VLP/ALP Print option, can be added to most machines already in operation. It can be done in the field, but is a bit more involved.

Thermwood’s LSAM large scale additive systems are the most widely used large scale composite thermoplastic additive equipment in industrial production today. Virtually all, if not all, large scale additive systems installed in the last several years have been Thermwood LSAMs. Processing a variety of reinforced composite polymers from room temperature ABS and PC to high temperature material such as PSU, PESU and PEI, they are used to produce molds and tools for the aerospace industry, patterns for the foundry industry and for a variety of other unique applications.

LSAM systems are available in sizes from 5x10 foot to 15x60 foot in a variety of configurations including print only and full print and trim, making it the broadest product offering in the large scale additive arena. Print heads are available that can print thermoplastic composite material at rates from 200 pounds per hour to over 500 pounds per hour.

They have a variety of exclusive features including a temperature controlled compression wheel and automatic thermal layer speed control, both of which help assure the best possible fusion between printed layers.

With the addition of Angle Layer Print, these systems have become even more capable and more flexible.

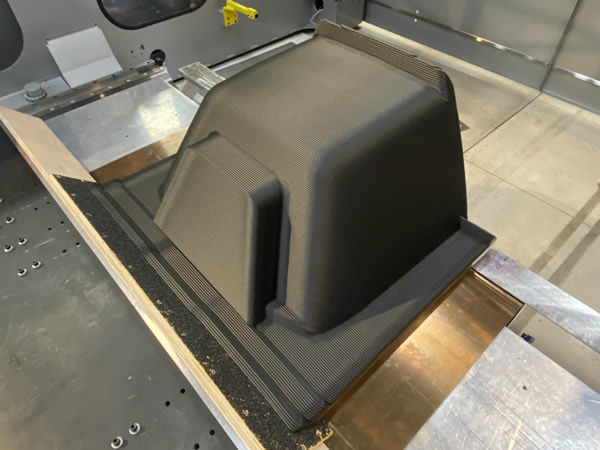

Finished LSAM Angle Layer Print (rear view)

Finished LSAM Angle Layer Print (front view)

Posted by Duane Marrett on Thu, Oct 25, 2018

Tags: Thermwood, Announcements, aerospace, 3D printing, Additive, LSAM, 3D Print, Thermwood LSAM, Additive Manufacturing, Vertical Layer Printing, VLP

Thermwood has released a Vertical Layer Printing (VLP) option for its LSAM (Large Scale Additive Manufacturing) machines. This option allows parts to be printed which are as long as the machine table itself.

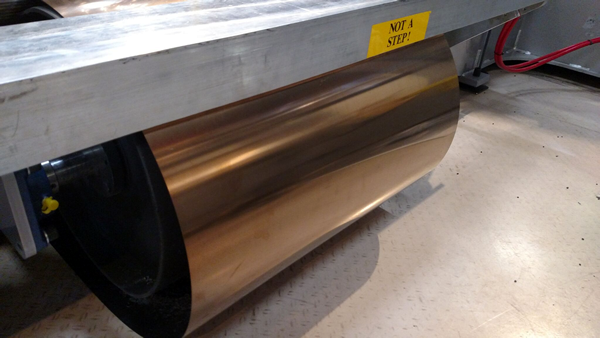

It does this by adding a second moving table, mounted perpendicular to the main fixed horizontal table. As layers are printed, this vertical table moves after each layer is printed, growing the part along the length of the machine rather than growing it upward. Thermwood’s “controlled cooling” print technology minimizes sag, which might otherwise pose a serious problem if the part were kept at an elevated temperature, as is common with traditional thermoplastic composite printing.

As previously announced, one of the initial parts printed with this system is a 12 foot long, carbon fiber reinforced ABS trim fixture for use in the production of the Boeing 777X aircraft.

During development, Thermwood has vertically printed and validated the use of a variety of polymers, including high temperature materials such as PSU, PESU and PEI with good results. It appears that parts printed using VLP are structurally and functionally identical to parts printed in the traditional horizontal layer orientation.

This means that, just as with traditional horizontally printed LSAM parts, molds and tools printed using VLP maintain vacuum in an autoclave to aerospace standards right from the machine, without the need for any type of external coating.

During VLP printing, the growing part rides on Teflon coated stainless steel belts. The belts and table drives (which can be fitted to any LSAM that is at least 20 feet long), have been designed to process parts which weigh up to fifty thousand pounds. Thermwood believes that this is more than adequate for anything customers are considering today.

The main advantage of Vertical Layer Printing is that long parts can be printed in one piece.

While it might be faster to print multiple sections of a large part simultaneously, they must then be bonded together so that they can be machined as a single piece. There are some disadvantages to this approach:

VLP has been designed so that the machine can be reconfigured from standard horizontal layer printing to vertical layer printing or back again in a matter of a few hours. It is clear that technology exists, right now today, to 3D print large autoclave capable aerospace tooling on a production basis. Thermwood has already been granted patent protection on key aspects of its Vertical Layer Print technology.

LSAM is based on exciting new technology developed from an entirely new direction.

LSAM is intended for industrial production. It is not a lab, evaluation or demonstration machine, but is instead a full-fledged industrial additive manufacturing system intended for the production of large scale components.

Thermwood has already applied for 19 separate patents on various aspects of this new technology (several have already been granted and more will be coming as development continues). LSAM is truly “state of the art” in this exciting new world of Large Scale Additive Manufacturing.

Posted by Duane Marrett on Tue, Oct 09, 2018

Tags: Thermwood, Announcements, aerospace, 3D printing, Additive, LSAM, 3D Print, Thermwood LSAM, Additive Manufacturing, Vertical Layer Printing, Boeing, VLP, 777x

Boeing and Thermwood have employed additive manufacturing technology to produce a large, single-piece tool for the 777X program. The project is demonstrating that additive manufacturing is ready to produce production quality tooling for the aerospace industry.

Thermwood used a Large Scale Additive Manufacturing (LSAM) machine and newly developed Vertical Layer Print (VLP) 3D printing technology to fabricate the tool as a one-piece print, eliminating the additional cost and schedule required for assembly of multiple 3D printed tooling components. In the joint demonstration program, Thermwood printed and trimmed the 12-foot-long R&D tool at its southern Indiana demonstration lab and delivered it to Boeing in August 2018.

Boeing Research & Technology engineer Michael Matlack believes the use of Thermwood’s additive manufacturing technology in this application provided a significant advantage, saving weeks of time and enabling delivery of the tool before traditional tooling could be fabricated.

The tool was printed as a single piece from 20% carbon fiber reinforced ABS using the Vertical Layer Print system. Boeing purchased a Thermwood LSAM machine with the VLP functionality for the Interiors Responsibility Center (IRC) facility in Everett, Washington.

The ability to quickly produce large-scale tooling at a quality level suitable for a real world production environment represents a significant step in moving additive technology from the laboratory to the factory floor.

LSAM is based on exciting new technology developed from an entirely new direction.

LSAM is intended for industrial production. It is not a lab, evaluation or demonstration machine, but is instead a full-fledged industrial additive manufacturing system intended for the production of large scale components.

Thermwood has already applied for 19 separate patents on various aspects of this new technology (several have already been granted and more will be coming as development continues). LSAM is truly “state of the art” in this exciting new world of Large Scale Additive Manufacturing.

The Secret to LSAM Print Quality...A Different Process

© Thermwood Corporation. All Rights Reserved