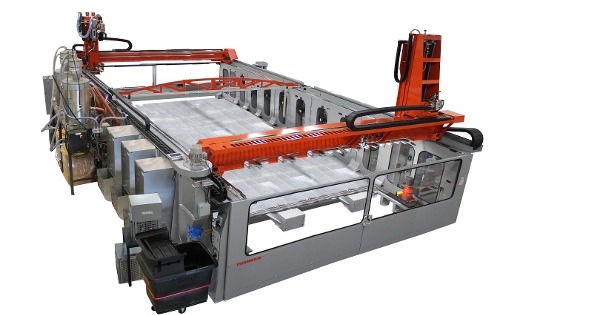

Another LSAM 1540 is in the works — what could YOU build with this additive titan?

Thermwood is building another powerhouse in our LSAM (Large Scale Additive Manufacturing) line — a high-performance 1540 model designed to produce massive, high-precision components.

This system is packed with advanced capabilities:

Print Gantry:

Patented 60mm melt core

Prints up to 500 lbs per hour

Handles both low- and high-temp thermoplastics

Operates at temperatures up to 450°C

60" vertical stroke for tall part production

Self-contained fume and smoke collection system

5-Axis Trim Gantry:

72" vertical stroke

362° horizontal and 270° vertical rotation

Multi-axis feed speeds up to 2,100 inches per minute

High-performance 24HP, 24,000 RPM variable-speed router

12-position automatic tool changer located under the gantry

Automatic lubrication system for reduced maintenance

High-tolerance automatic tool length sensor

Superior chip collection system

Can print and trim at the same time — no part relocation needed

Three Print Orientations:

Vertical Layer Printing (VLP): Print full-length parts in a single section

Standard Horizontal Printing

Angle Layer Printing (ALP): Print at a 45° angle for complex geometry

This LSAM 1540 is built for speed, scale, and flexibility — and it's almost ready. Stay tuned for updates as it nears completion!

Learn More About LSAM

LSAM 1540 Shown