Live Printing

For CAMX 2022 in Anaheim, CA on October 18th-20th, Thermwood will be printing LIVE on an LSAM Additive Printer 510 – two sections of a multi-piece layup tool each day using Airtech Advanced Materials Group Dahltram™ C-250 CF carbon fiber reinforced PC material. LSAM Research Laboratory at Purdue ADDITIVE3D Software will be on display as well, with Purdue representatives on site for demonstrations. We will also have several large customer-created large scale tools on display from Airtech, Ascent Aerospace, General Atomics and more.

This promises to be an exciting demonstration of the LSAM Additive Printer Large Scale Additive System in Booth #W2.

LSAM Research Laboratory at Purdue ADDITIVE3D Software on Display

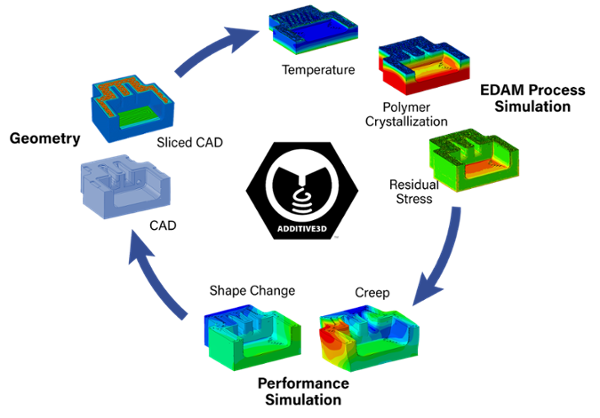

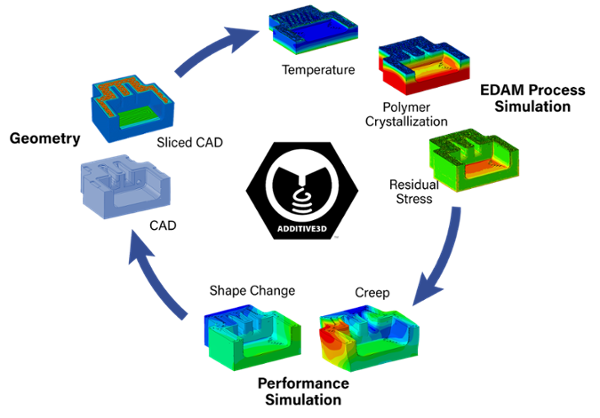

Representatives from the Thermwood Research Laboratory at Purdue University (located in Purdue University's Composites Manufacturing Simulation Center - CSMC) will also be on hand to demonstrate their ADDITVE3D simulation software.

We will be printing two sections of a multi-piece layup tool each day using Airtech Advanced Materials Group Dahltram™ C-250 CF carbon fiber reinforced PC material

About the LSAM Additive Printer

The LSAM Additive Printer systems are single gantry, moving table configurations and are available in two table sizes, 5’x5’ and 5’x10’. The 5’x10’ table is available in two configurations, 5’ wide with 10’ of front to back motion and 10’ wide with 5’ of front to back motion. Choice of configuration depends on several factors, fitting it existing factory floor space is one factor.

The specially designed, highly rigid tab and slot, structural steel gantry also incorporates a fume extraction system that pulls print fumes through specially designed activated charcoal filters to remove them and “sweeten” the air.

LSAM additive Printers use the exact same print head mechanism as all the other, including the largest LSAM Systems which means that they produce the same amazing print quality that has made LSAM the leader in large scale additive printing. They also use the same highly advanced Ultra 6 control with all its exclusive, patented print features and capability.

The systems come standard with a single hopper polymer dryer for applications that don’t change print material very often. For installations that print a wider variety of materials, a dual hopper dryer is available as an option.

An enclosure that surrounds the machine is also available. The machine with the full enclosure can also be built to meet European CE standards.