Byrne Custom Woodworking works to focus on the details customers want.

“I find that customers these days are so much more educated in the level of craftsmanship and attention to detail,” said company president Ian Byrne. “Any personal details such as carvings or other architectural elements that we can include in our projects are always so appreciated.”

The Lenexa, Kansas, company makes custom cabinets and architectural millwork, both for residential and commercial customers.

“We do quite a lot of church projects,” Byrne said. “I am really happy that the design trends have gone back to Gothic and traditional styles. It has been quite adventurous designing and producing some of these elements with our CNC.”

Byrne has been using a Thermwood Cut Ready CNC machining center to handle the special requests from customers.

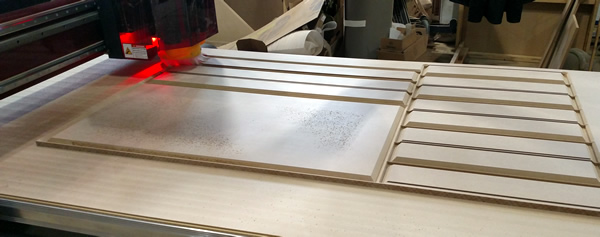

Thermwood Cut Ready CNC router has helped Byrne achieve maximum panel yield.

Thermwood Cut Ready CNC router has helped Byrne achieve maximum panel yield.Ian Byrne started the business in nearby Kansas City in 1989. Fifteen years ago, he moved the company underground – to a former limestone mine with vast galleries and underground space. This underground world is home to dozens of businesses and is known officially as the Meritex Lenexa Executive Park.

The move underground came about when Byrne purchased a large panel saw that was operated by a company making laminate casegoods that planned to close. That company had a large SCMI panel saw and edgebander. The panel saw, it turned out, was too large to move out of the cave.

So Byrne moved in, and they’ve been happy in their underground space since.

The caves resemble a movie set, where it never gets too hot or too cold. When it is bitterly cold outside, it is still warm deep in the caves. And the lack of large temperature and humidity extremes minimizes wood changes.

“The upside is a controlled environment with regard to humidity and temperature. It is very comfortable all year round and the wood loves it,” Byrne said. “The downside is we have to transport our product for finishing to another facility.”

The finish shop is located above ground, in West Bottoms near downtown Kansas City.

Customers and markets

Most work is residential, and general manager Donovan Mumma said that some larger residential jobs are handled as a commercial job would be.

One recent job was for a large 30,000 square foot house, including large walnut closet cabinets, gun cabinets, and pecky cypress.

Mumma said that alder was very popular, and has replaced cherry in many applications.

Also, reclaimed wood continues to be popular for furniture and faux beams. Byrne gets this wood from a number of sources, including old barns.

Byrne also makes plantation shutters, using paint grade basswood and poplar.

“We built a library for a client using walnut,” Byrne said. “They insisted that the shutters in the doors and windows also be fabricated using walnut. So we made the necessary jigs and tooling and the shutter department was born.”

Other projects have included a large curved desk with flex plywood, and many altars, candle stands and other pieces for churches.

They also make their own doors and drawers in house.

“Because we do so many varied projects and styles, it is nice to have the capability to fabricate two or four custom doors for a furniture piece when needed,” Byrne said. “It is also a good way to keep your employees busy during slower times. When really busy, we will buy out the doors and drawers.”

Byrne doesn’t use melamine or particleboard as a rule, unless is it requested. The company’s primary panel product is a UV-cured plywood sheet stock with birch or maple UV coated on both sides.

“We stay in the mid- to high-end market,” Byrne said. “I saw this material as a top of the line cabinet liner. The coating is extremely durable and looks classy. It also makes the finishing process a lot easier. Columbia Forest Products is one of the manufacturers.”

Altars made by Byrne for St. Francis. Byrne said he is happy that the design trends have gone back to Gothic and traditional styles.

Altars made by Byrne for St. Francis. Byrne said he is happy that the design trends have gone back to Gothic and traditional styles.Maximum panel yield

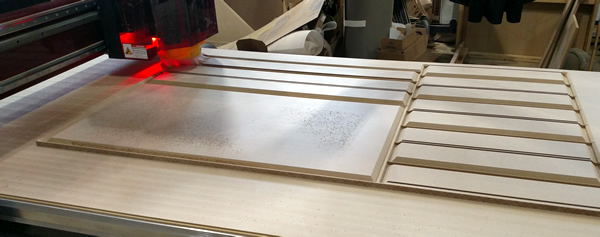

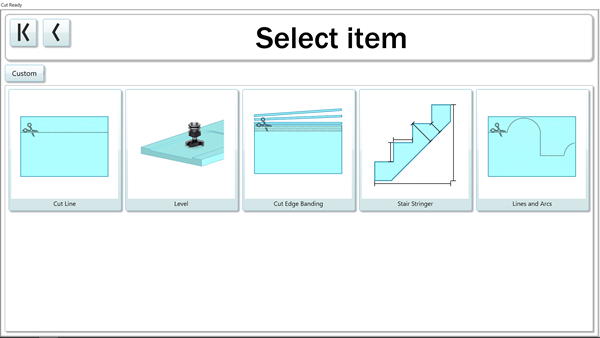

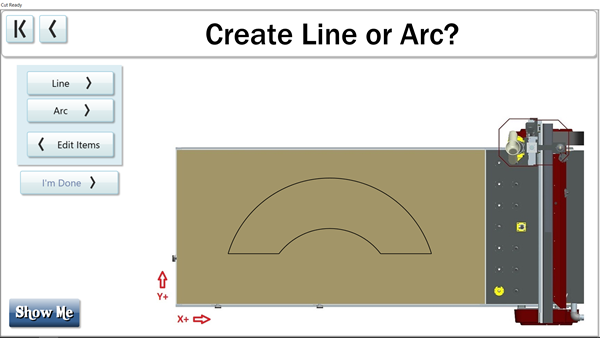

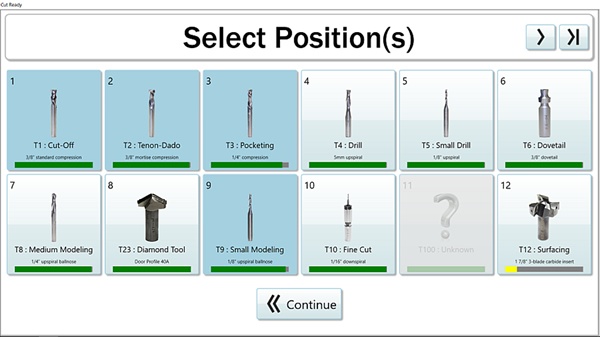

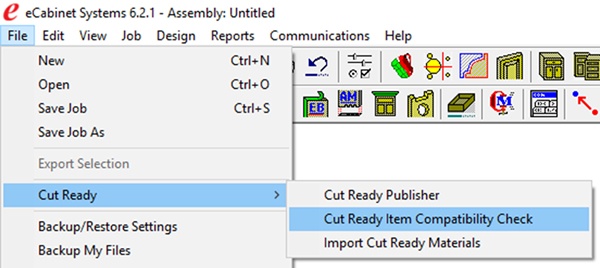

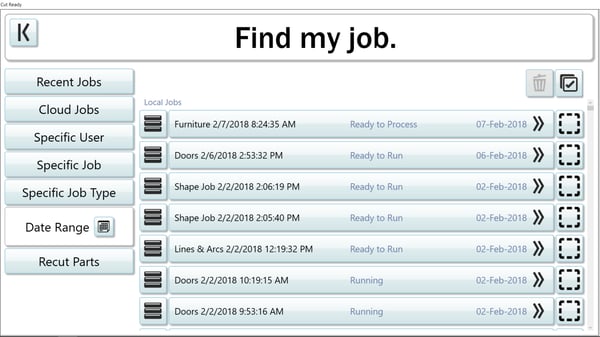

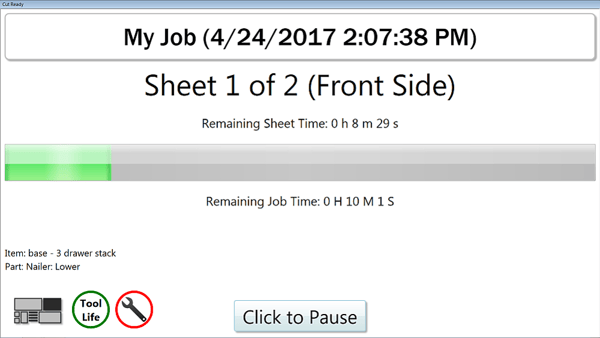

The Thermwood Cut Ready CNC router has helped Byrne achieve maximum panel yield, and cuts the offal pieces in a way so they can be used again. The operator follows instructions on the Cut Ready’s screen.

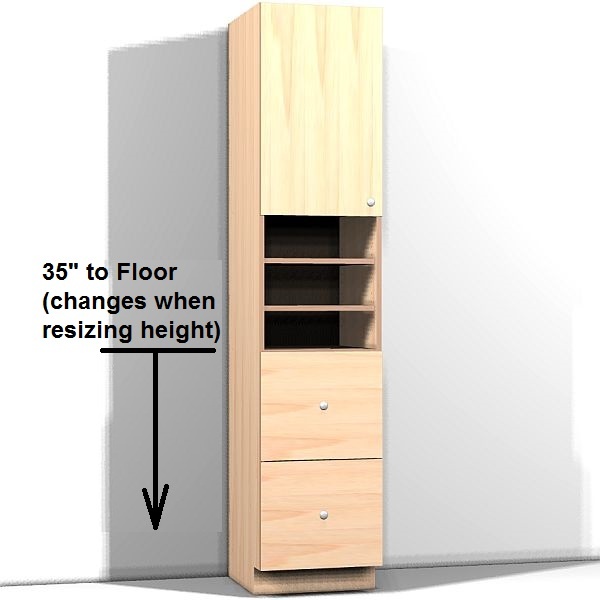

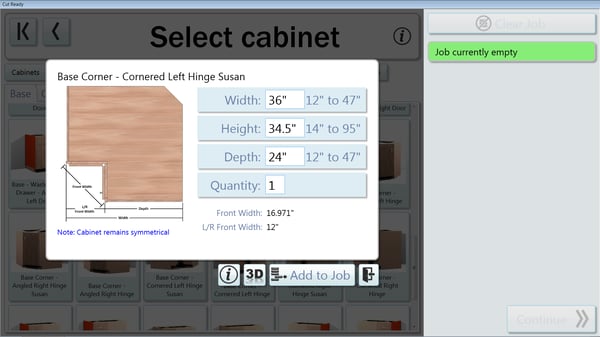

Mumma said that the Cut Ready comes with a library of face frame and frameless cabinet designs already installed. Byrne could use or modify those existing designs. Mumma also uses the Aspire program for 3-D modeling.

Cut parts are labeled with a barcode that includes job and part number, and a figure showing any edgebanding required.

Then the cut pieces go directly to the edgebander or to assembly. Mumma believes that the investment in the Cut Ready may have already paid off for the company.

There was a learning curve, and Byrne did hire a CNC programmer. Mumma said the company was not completely new to CNC. They did have a point-to-point machine, and had earlier outsourced some work to an outside CNC shop.

Mumma said the quality of the cut materials is better. Blind dadoes allow a box to be put together and stay together before glue and fasteners are installed. This also saves time in assembly.

Cut Ready also allows them to make certain pieces in house that they used to outsource. “The Cut Center is dummy-proof,” Mumma said.

They were able to use the existing Cut Center library on other jobs. Mumma said that Cut Center also keeps track of tool wear on different tooling spindles after a baseline time is entered.

“Versatility comes to mind at first thought,” Byrne said of the Thermwood. “I truthfully believe we can take on any project and with the combination of our expertise and the versatility of this machine, we will be successful.”

Thermwood Cut Ready allows them to make certain pieces in house that they used to outsource.

Thermwood Cut Ready allows them to make certain pieces in house that they used to outsource.Doors and drawers

Byrne has 20 employees, including two installers and two in the finishing shop.

Mumma said they use Cabinet Vision, and he also uses Google SketchupPro 3D modeling to visualize projects.

The door and drawer department, and another cut-out area can cut pieces on smaller machines.

The panel saw that couldn’t be moved is still in use and performs well. This is an SCMI Alfa 320 panel saw that is from about 1994. An SCMI edgebander from the same time period is also still in service. A Ritter edge sander is also used.

Dust collection is done the usual way, with metal pipes and a dust collector on the outside of the main shop area, also underground. Local schools take the sawdust to use on their own projects.

The door and drawer department, and another cut-out area can cut pieces on smaller machines. Cabinet Vision is used in the shop.

The door and drawer department, and another cut-out area can cut pieces on smaller machines. Cabinet Vision is used in the shop.Software and spirit

Byrne said his outlook for 2018 is good. “We have a great team of enthusiastic designers and craftsman and craftswomen. (We have) lots of work on the board and plenty of prospects in the wind.

“We have recently invested in software to integrate our technologies as one. I want to expand our procurement of sacred spaces projects. For centuries around the world, some of the most incredible craftsmanship can be found in the churches and cathedrals.

“I would like our company to be a part of that legacy!”

Ian Byrne’s creativity isn’t limited to wood. He is lead singer for The Elders, a Kansas City-based band that is planning a final year of concerts in 2018. “It’s all in the hands and the heart! I have also surrounded myself with great craftsmen and talented musicians. This has led to enjoying success in both fields.”

Most work is residential, and some larger residential jobs are handled as a commercial job would be.

At a glance

Byrne Custom Woodworking

Lenexa, Kansas

Custom cabinets and architectural millwork

Employees: 20

http://www.byrnecustomwood.com

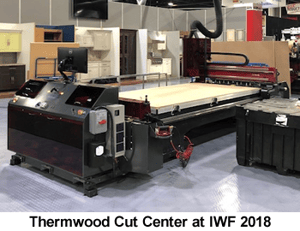

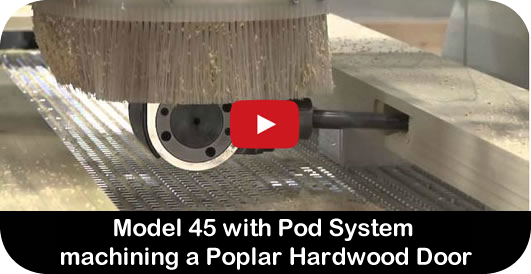

We will also be demonstrating solid wood, aluminum and plastic sheet parts on the Thermwood MODEL 45, utilizing a pod system and aggregate tooling.

We will also be demonstrating solid wood, aluminum and plastic sheet parts on the Thermwood MODEL 45, utilizing a pod system and aggregate tooling. The CUT READY 43, the CUT CENTER and the MODEL 45 will all be on display and cutting live at IWF 2018 (Thermwood booth #6735). We will also have several displays created on the CUT CENTER, as well as some created by our customers, like this outdoor kitchen, designed and machined by Timberwood Properties in Leesburg, FL .

The CUT READY 43, the CUT CENTER and the MODEL 45 will all be on display and cutting live at IWF 2018 (Thermwood booth #6735). We will also have several displays created on the CUT CENTER, as well as some created by our customers, like this outdoor kitchen, designed and machined by Timberwood Properties in Leesburg, FL .

Every CNC router, regardless of price, has one thing in common..it must be programmed. You will need a CNC programmer. You will also need an operator with knowledge of tooling, feed speeds and holddown.

Every CNC router, regardless of price, has one thing in common..it must be programmed. You will need a CNC programmer. You will also need an operator with knowledge of tooling, feed speeds and holddown.