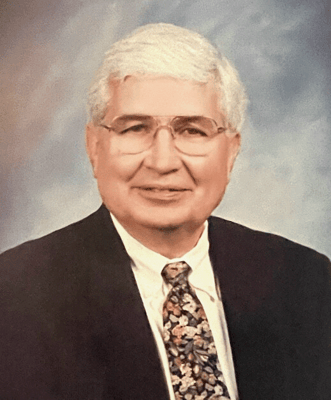

Thermwood Representative, Donald “Don” Jones, 80, of Denton, North Carolina passed away on Monday, August 21, 2023 surrounded by family and friends.

Thermwood Representative, Donald “Don” Jones, 80, of Denton, North Carolina passed away on Monday, August 21, 2023 surrounded by family and friends.

For approximately 40 years, Don represented Thermwood CNC equipment, initially through J & G Machinery, then as the visionary founder and President of Cutting Edge Machinery. His dedication and passion for the industry were evident to all who had the privilege of working alongside him.

Don was born to Lewis and Alice (Proctor) Jones, September 15, 1942 in Guilford County, NC. He graduated from Ledford High School in 1960 and was voted most likely to succeed. Don was married to the love of his life, Gale (Knight) Jones, for 45 years.

Don was known not only for his professional achievements but also for his warmth, wisdom, and delightful sense of humor. His easy-going manner and quick wit endeared him to all who had the privilege of crossing his path.

While we mourn his passing, we find solace in knowing that Don's legacy will continue. His son, Vann, will proudly carry forward the mantle of Cutting Edge Machinery as Advanced Cutting Edge, LLC and Thermwood representation, ensuring that Don's vision and dedication live on.

Don leaves behind a lasting impact on our hearts and in the industry he so passionately served. His memory will be cherished by family, friends, and colleagues.

Thermwood Corporation is grateful for Don’s many years of association and is honored by his longstanding dedication in representing the company.

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible

Brenton Rumple is the son of Joseph and Megan Rumple of Ferdinand, IN. He is a graduate of Forest Park High School.

Brenton Rumple is the son of Joseph and Megan Rumple of Ferdinand, IN. He is a graduate of Forest Park High School.  Brayton Rumple is also the son of Joseph and Megan Rumple of Ferdinand, IN. He is a graduate of Forest Park High School.

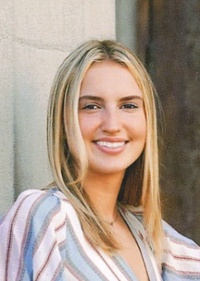

Brayton Rumple is also the son of Joseph and Megan Rumple of Ferdinand, IN. He is a graduate of Forest Park High School.  Olivia Susnjara is the daughter of April and Jason Susnjara of Santa Claus, IN. She is a graduate of Heritage Hills High School.

Olivia Susnjara is the daughter of April and Jason Susnjara of Santa Claus, IN. She is a graduate of Heritage Hills High School.  Sylvia Wright

Sylvia Wright  Logan Lehmkuhler,

Logan Lehmkuhler,  Dayton Campell,

Dayton Campell,