Thermwood to Demonstrate New Auto-Labeling and Unload System on Model 43 and Solid Wood Machining on Model 45

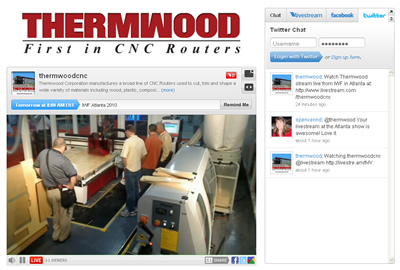

The 2013 AWFS Show (July 24th-27th) promises to be an exciting opportunity to visit Las Vegas and see the very latest in CNC Router technology from Thermwood!

For AWFS 2013, Thermwood is proud to demonstrate our affordable CabinetShop 43 CNC Router equipped with the new optional Auto Labeling and Unload Rake System for nested based production. This new system will be in action at AWFS 2013 in Booth #8400.

Featuring the CabinetShop 43 with New Automatic Labeling and Unload System:

Speed up Production Time

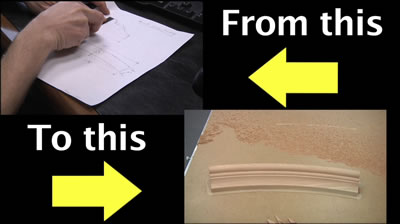

This new option helps save time by automating the process of placing labels and off-loading finished material. The automated system quickly places the labels and then machines the parts. It next unloads the finished material to a sorting table. This automatic and economical addition can greatly speed up production time, and is available both on new machines and as a retrofit.

Also at AWFS we will be demonstrating a Fravol edgebander. Fravol, known for high quality edgebanders, is exclusively represented and serviced in the US by Thermwood.

Also Demonstrating Solid Wood Machining on the Thermwood Model 45

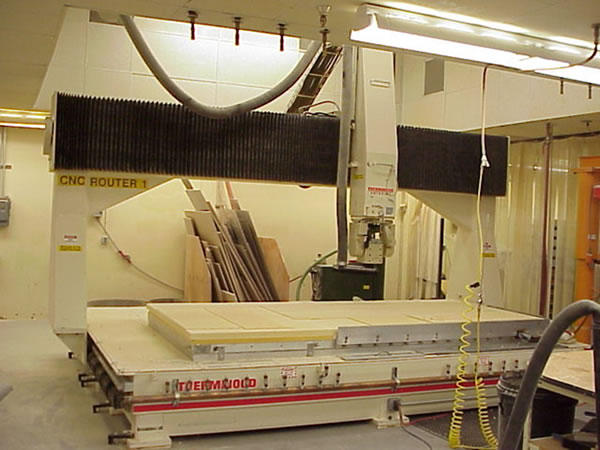

We will also be demonstrating solid wood machining utilizing the Nemi Pod Hi-Flow System on our Thermwood Model 45.

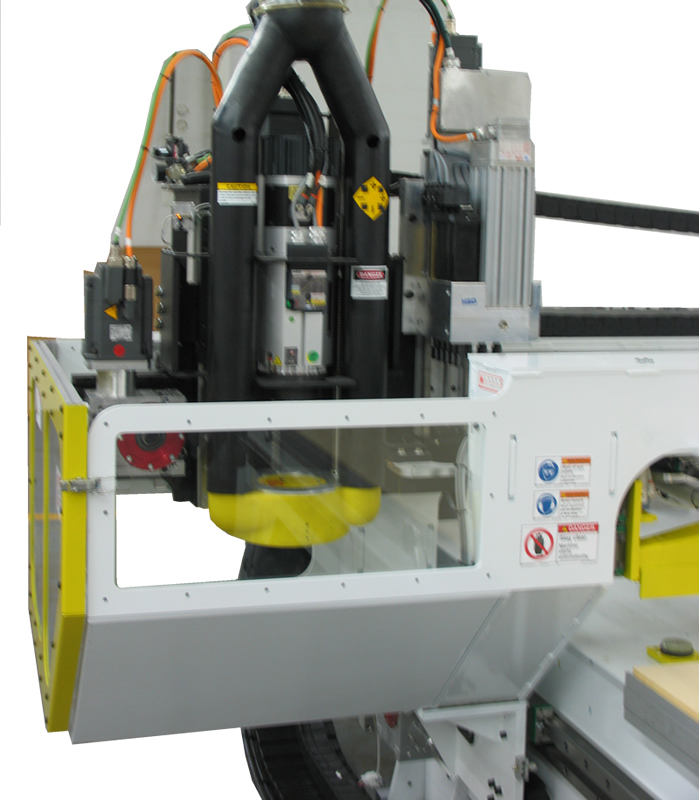

The heavy-duty Model 45 is designed for a variety of functions including the machining of rotary operations when equipped with our optional C-Axis. This expands the capability of this already useful machine to include volutes, carvings, chair parts, stair components and much more.

See at AWFS:

This new system will be in action at AWFS 2013 (July 24th-27th) in Booth #8400.

Features:

Features:

Training at Thermwood is conducted in a modern, comfortable and well equipped center devoted specifically to educating our customers. This is, by far, the fastest and most efficient way to learn. Over the years, Thermwood has experienced the ups and downs of training at the customer's facility, the interruptions and distractions, not to mention the lack of classroom facilities and equipment. It just doesn’t work very well. At Thermwood, the atmosphere contributes to the learning experience. Each classroom is setup specifically for the course being taught.

Training at Thermwood is conducted in a modern, comfortable and well equipped center devoted specifically to educating our customers. This is, by far, the fastest and most efficient way to learn. Over the years, Thermwood has experienced the ups and downs of training at the customer's facility, the interruptions and distractions, not to mention the lack of classroom facilities and equipment. It just doesn’t work very well. At Thermwood, the atmosphere contributes to the learning experience. Each classroom is setup specifically for the course being taught. Our machine operator/programmer courses are located adjacent to the machine training lab, where students complete the prescribed projects on a specific training machine utilized only for training purposes. Our application software classes are conducted in a classroom with state-of-art computer equipment. Then when it comes time for practical applications on a full sized machine, Thermwood's training lab is equipped with a

Our machine operator/programmer courses are located adjacent to the machine training lab, where students complete the prescribed projects on a specific training machine utilized only for training purposes. Our application software classes are conducted in a classroom with state-of-art computer equipment. Then when it comes time for practical applications on a full sized machine, Thermwood's training lab is equipped with a  Thermwood also has a customer lounge and workstation available for use during your training at our facility. This comfortable area features free:

Thermwood also has a customer lounge and workstation available for use during your training at our facility. This comfortable area features free: Our five-day machine programming/operations training here at Thermwood is the first step to helping you hit the ground running. The goal is to help you understand how to utilize the power of your Thermwood CNC Router and

Our five-day machine programming/operations training here at Thermwood is the first step to helping you hit the ground running. The goal is to help you understand how to utilize the power of your Thermwood CNC Router and