Thermwood has added thermographic imaging as a standard feature to our large scale additive manufacturing machines (which we call LSAM "L-Sam"). This addition makes it easier to adjust and control the printing process, resulting in the best possible printed structures.

Know and Control the Temperature

In order to print high quality, void free large scale 3D printed structures, the previous layer must be cool enough to support the new layer without distortioin, but must also be warm enough to fuse completely with the new layer as it is applied. To accomplish this, we must first know and be able to control the temperature of the surface throughout the printing process. There is a narrow range of temperatures for each material where 3D printing is optimal. The goal is to continuously operate within that range.

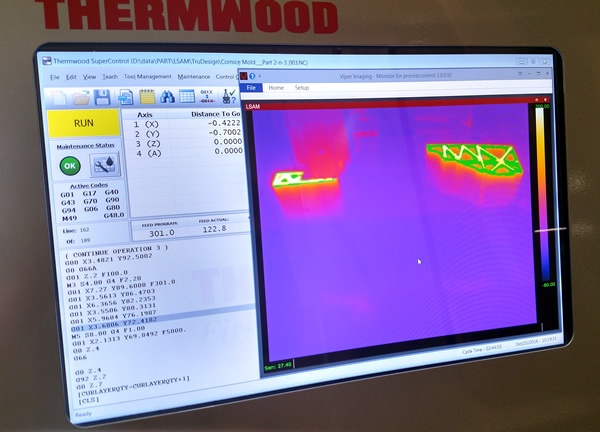

Real-time Full Color Thermal Image of the Part

Thermwood’s new thermographic imaging system shows the operator a full color thermal image of the part as it is being printed. In this image, different colors depict different surface temperatures of the part. With our system, a green color, is assigned to the ideal range of temperatures for the material being printed. The thermal image is displayed on the control screen in a movable, resizable window. The goal is to continuously print on green.

Easily Adjust Print Speed and Temperature

Once print temperatures are known and the ideal print temperature can be identified, Thermwood’s print head control makes it easy to adjust printing parameters to achieve the ideal print surface temperature. If the part becomes too hot, fan cooling can be increased or print speed can be reduced to allow more cooling time between layers. If the part temperature becomes too cool, print speed can be increased or cooling can be reduced.

LSAM High-Output Print Heads Are Important

Thermwood’s high output print heads are also important to quality printing of large parts. In the past, trying to print large parts with low output print heads presented a different thermal problem. Slow print speeds prevented the print head from returning to a point before it becomes too cool to achieve a proper layer to layer bond. With Thermwood’s high output print heads (our largest prints up to 500 lbs/hr) this is no longer a problem. Really good quality large thermoplastic composite parts can be made. Our new thermographic imaging system provides temperature guidance and helps the operator to consistently achieve the desired results.

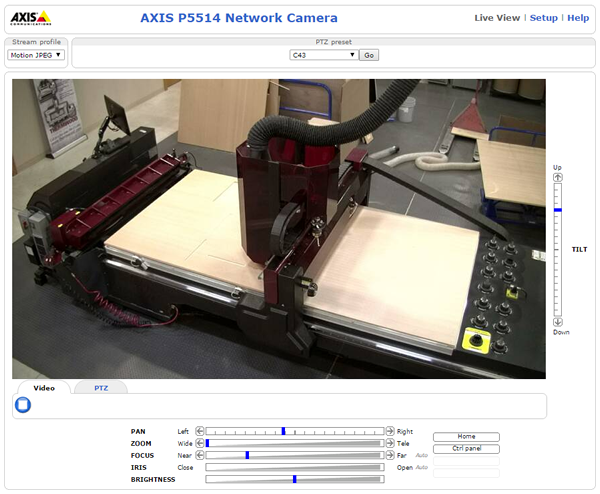

Three Different Thermographic Camera Mounting Locations

The thermographic camera can be mounted in three different locations. The first is a fixed position on a stand, inside the machine, looking at the part. The second mounting position is on the print gantry. This works well for parts that are too large to view as a single image. The camera can also be mounted to the print head itself, for special applications. Image output from the camera is integrated with Thermwood’s print gantry CNC control and the full color temperature image is displayed on a resizable window right on the control display itself. A touch screen allows the operator to touch any point on the image and read the exact temperature of that point.

The thermographic camera can be mounted in three different locations. The first is a fixed position on a stand, inside the machine, looking at the part. The second mounting position is on the print gantry. This works well for parts that are too large to view as a single image. The camera can also be mounted to the print head itself, for special applications. Image output from the camera is integrated with Thermwood’s print gantry CNC control and the full color temperature image is displayed on a resizable window right on the control display itself. A touch screen allows the operator to touch any point on the image and read the exact temperature of that point.

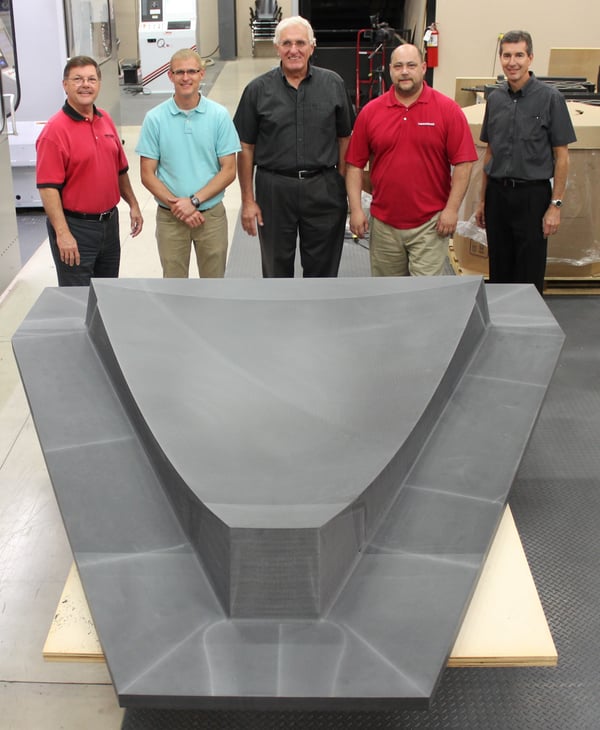

LSAM Produces Solid, Void-free Parts

Using this technology, Thermwood has been able to produce large tools that are solid and void free enough to maintain vacuum without sealing or surface coating. This simplifies production of the tool, allowing accurate machining of the surface without having to deal with distortions that might be caused by variations in the thickness of a coating.

Print and Trim on the Same Machine

Thermwood offers a line of dual gantry additive manufacturing machines which both print and trim parts on the same machine. These machines can be up to 100 feet long with print head output rates from 150 to 500 pounds per hour.

The Thermwood LSAM is used to produce large to very large sized components from reinforced thermoplastic composite materials.

Although suitable for producing a wide variety of components, Thermwood is focusing on producing industrial tooling, masters, patterns, molds and production fixtures for a variety of industries including aerospace, automotive, foundry and boating.

The

The