CNC Doesn't Have to Be Complicated

If you’ve ever felt overwhelmed by CNC technology, you're not alone. For many, the idea of programming, machine calibration, and navigating complex software feels like a steep learning curve. But what if you could walk into the AWFS Fair with zero CNC experience—and walk out ready to run your own shop?

That’s not a dream. It’s the Thermwood Cut Center experience.

Welcome to the next generation of AI-driven CNC technology.

See It. Run It. Rethink What’s Possible.

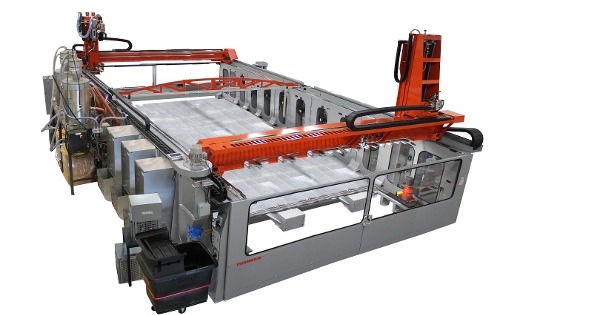

At the heart of our innovation is the Thermwood Cut Center, a cutting-edge CNC system powered by artificial intelligence. It’s designed to simplify cabinet, door, drawer, and furniture production with:

- No programming required

- No guesswork

- Step-by-step, real-time guidance

Just tell the machine what you want to make, and it does the rest. Optimizing your design and executing precision cuts with ease.

Experience It Live at AWFS Fair 2025

This isn’t your typical demo.

At Booth #2523, you’ll get to:

- See the Cut Center in action

- Try it yourself: hands-on

- Discover how fast and easy CNC machining can be

Whether you’re a seasoned professional or completely new to CNC, the Thermwood Cut Center empowers you to deliver high-quality results with confidence from day one.

AWFS Special Show Offer: Over $6,500 in FREE Tooling

To celebrate AWFS 2025, we’re offering an exclusive deal you won’t want to miss:

🎁 FREE MDF Door Profile Diamond Tooling Kit

(A $6,587 value)

When you purchase a new Thermwood Cut Center by August 31, 2025

This professional-grade tooling kit is essential for precise door profiling and adds even more value to your investment: https://bit.ly/4eEmhOG

Claim Your Free AWFS Show Pass — Courtesy of Thermwood

Want to see the Cut Center in person? We’ve got you covered.

Click below to claim your FREE show pass and join us at Booth #2523:

Final Thoughts

The Thermwood Cut Center is more than a machine—it’s a game changer for woodworkers, cabinetmakers, and shop owners. By removing complexity and infusing intelligence into every step, it redefines what's possible in CNC production.

Join us at AWFS Fair and experience it for yourself.

You’ll leave inspired, informed, and ready to take your business to the next level.

Cruz Meece – Son of Natalie and Jeff Meece of Huntingburg, IN, and a graduate of Southridge High School.

Cruz Meece – Son of Natalie and Jeff Meece of Huntingburg, IN, and a graduate of Southridge High School.

Olivia Vote – Daughter of Amanda and Nicolas Vote of Newburgh, IN, and a Collegebound AP Scholar graduate of Castle High School.

Olivia Vote – Daughter of Amanda and Nicolas Vote of Newburgh, IN, and a Collegebound AP Scholar graduate of Castle High School.