What Do You Get With Thermwood?

When you join the Thermwood Family, we don't consider you a customer, but as a partner, friend and family member. We believe in helping each other through a genuine relationship of mutual trust to make us both successful.

What Do You Get With a Thermwood CNC?

When you purchase a CNC router from Thermwood, you get a dependable machine, a superior control, reliable performance and the best service and support in the business.

Our CNC Experts work with you during every step of the process to insure that you receive the optimum machine configuration for your specific application, and that you gain the knowledge and assistance you need to get into production as quickly as possible.

You Are Never On Your Own

You are never on your own with a Thermwood machine. Knowing that you have made the smart choice in partnering with a company that you can trust to stand behind you and do everything we can to make your business successful.

Our Machines Just Work!

From Day One, Thermwood machines just work! Day after day and year after year, our CNC machines will get the job done. Made in the USA by hard-working Americans building custom machines just for you and not for stock. And, because we build both the machines and controller, we support everything that comes from Thermwood...one company and one phone number to contact.

Thermwood Model 90 5 Axis 5'x12' Dual Table CNC router

Customize Your Solution

Thermwood's Total Solution means that we can customize your machine operation to suit your specific needs. Our experienced program techs can create new programs or modify your existing programs, work with you on fixturing and tooling, and much more.

Thermwood's Total Solution means that we can customize your machine operation to suit your specific needs. Our experienced program techs can create new programs or modify your existing programs, work with you on fixturing and tooling, and much more.

Our ultimate goal is to provide the best solution possible with the lowest learning curve for you. We'll stay by your side during each step of the way. We also provide phone, email and forum support, always free of charge.

Thermwood Customers IDL Worldwide with their new Model 45 CNC router

Superior Support When You Need It

Our Total Solution also means that support doesn't stop with the sale. We are by your side during your five-day training course at Thermwood's state-of-the-art factory as well as during installation at your facility. And, if you ever need service or support, we have Virtual Service, free phone and email support, extensive parts inventory and the best support in the business!

Thermwood Customers learning programming skills during our five-day training class

The Thermwood Total Solution:

Training and Production Support

- In-Depth Machine Training at our state-of-the-art facilty

- Production Start-Up Assistance at your facility with a dedicated CNC Expert

- Help from our CNC Experts when you need it via phone/email/forum

Customizing Your Solution

- Customizable Machine Operation (modify/create new programs and/or machine hardware)

Better Machines

- High-Performance, Highly-Reliable, American-Built Machines

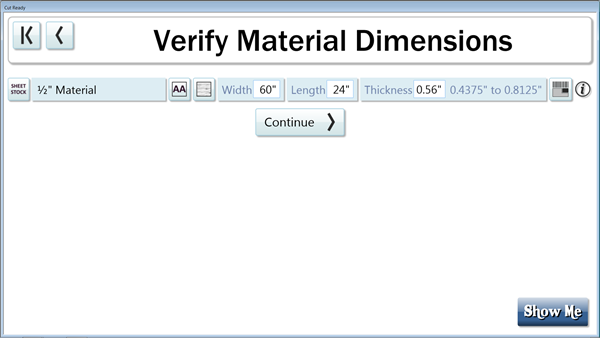

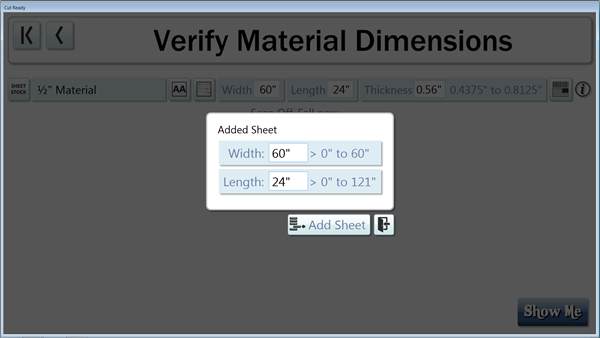

- Full Function, High Performance CNC Control (future-proofed with an upgrade path)

Superior Service and Support

- Free Phone/Forum/Email Support

- Virtual Service (instantly address virtually anything a service visit can - fast)

- Free Ongoing Control Updates (not available from others - you're stuck with what you have)

- Quick Support Visits Directly from the Factory When Needed (single source responsibility)

- Extensive Spare Parts Inventory with Overnight Shipping

Thermwood Customer Byrne Custom Woodworking with their new Thermwood Cut Center

The Bottom Line:

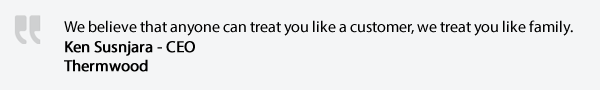

Our systems install fast, start up quick, are easier to use and maintain, produce more and last longer, and just plain work!

The Thermwood Total Solution means that we work with you before you buy, after you buy and into the future to make sure you get the best performance and financial benefit from your Thermwood machine.

Most people looking at a router for the first time do not realize that the vast majority of their cost will not be in running the router, but actually in EVERYTHING ELSE required to run the router (preparation, programming, hold down, operating procedures and error handling are the main cost areas).

Most people looking at a router for the first time do not realize that the vast majority of their cost will not be in running the router, but actually in EVERYTHING ELSE required to run the router (preparation, programming, hold down, operating procedures and error handling are the main cost areas).

The

The

The Thermwood

The Thermwood