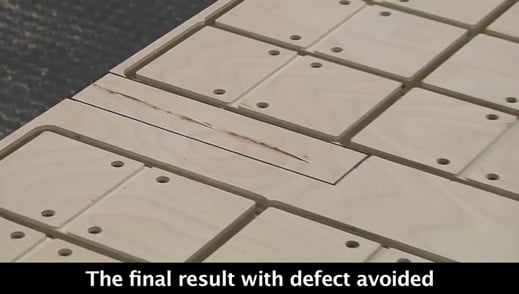

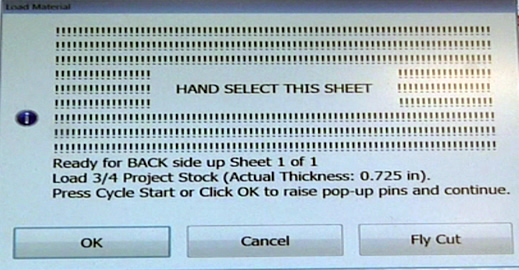

Smart-routers allow you to nest around defects to use damaged or flawed material. This feature can save you a lot of material, which in turn can save you a lot of time and money.

Smart-routers allow you to nest around defects to use damaged or flawed material. This feature can save you a lot of material, which in turn can save you a lot of time and money.

When using this feature on nested based jobs, a smart-router saves you money by reducing the amount of scrap material that is wasted. This in turn saves you a substantial amount of money, and ordinary routers just do not focus on this area. They rely on the user to take care of checking the material for flaws, and this means that the operator must be both skilled and well trained to work within the limits of these systems.

Smart-router Advantage

Smart routers address areas like this in a big way - they address the areas where you spend the most money because that’s where you can make the most money. Ordinary routers may seem less expensive at first, but may prove to be much more expensive in the long run.

|

Please click the "Request a Consultation" link above or give us a call at 1-800-533-6901 and we will sit down and show you how all this happens, in detail. |

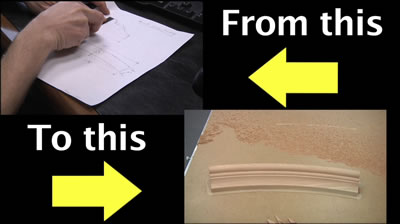

Replacing bad or scrap parts is really easy with a

Replacing bad or scrap parts is really easy with a

Smart-routers give you more

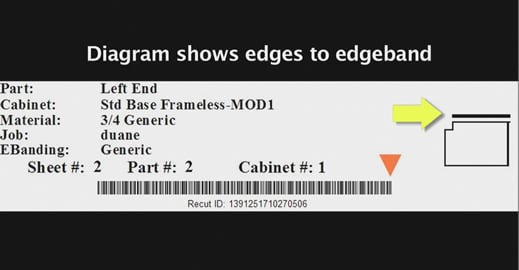

Smart-routers give you more Smart-routers alert you when running critical or prominent parts. Certain parts are prominent on the final product, door and drawer fronts for example.

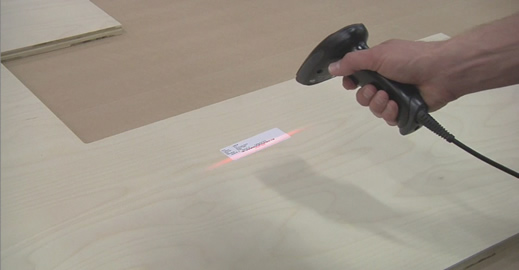

Smart-routers alert you when running critical or prominent parts. Certain parts are prominent on the final product, door and drawer fronts for example.  Smart-routers use smart labels to make parts easy to sort and edgeband.

Smart-routers use smart labels to make parts easy to sort and edgeband. AWFS 2013 (July 24th-27th) promises to be an exciting time to visit Las Vegas. This year, Thermwood is proud to demonstrate our affordable

AWFS 2013 (July 24th-27th) promises to be an exciting time to visit Las Vegas. This year, Thermwood is proud to demonstrate our affordable  Sign up below to schedule a time during the show to meet with one of our CNC Experts (Booth #8400). They will evaluate your production needs to determine how you can best reduce costs and increase efficiency. Plus, receive a FREE 2 GB Flash Drive during your meeting!

Sign up below to schedule a time during the show to meet with one of our CNC Experts (Booth #8400). They will evaluate your production needs to determine how you can best reduce costs and increase efficiency. Plus, receive a FREE 2 GB Flash Drive during your meeting!

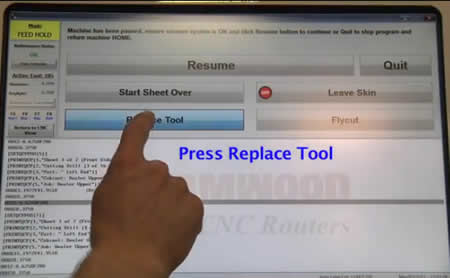

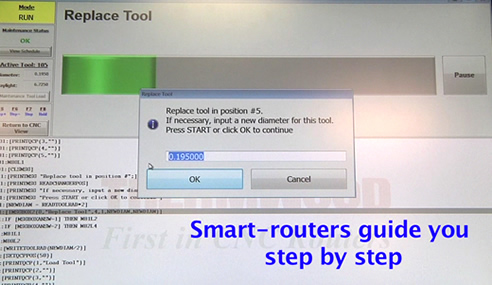

During program operation, smart-routers tell you what they are doing and offer instructions every step of the way. They tell you how many steps are in the program,what step they are on and what step is coming up next.

During program operation, smart-routers tell you what they are doing and offer instructions every step of the way. They tell you how many steps are in the program,what step they are on and what step is coming up next.