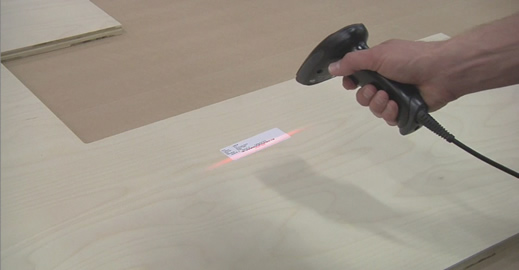

Replacing bad or scrap parts is really easy with a smart-router. At the end of a job, simply scan the labels of any parts you want to recut and the machine nests them on any material still on the table so you can recut them. This saves a lot over having to create new CNC programs to make replacement parts.

Replacing bad or scrap parts is really easy with a smart-router. At the end of a job, simply scan the labels of any parts you want to recut and the machine nests them on any material still on the table so you can recut them. This saves a lot over having to create new CNC programs to make replacement parts.

With a smart-router you can even add parts from previous jobs to a new job, provided you are running the same material (it monitors that for you). When replacement parts from another job are cut, a red bar on the label lets you know this part is for a different job.

Thermwood at AWFS 2013

Thermwood will be demonstrating many of the features of smart-router technology and nested based manufacturing at the 2013 AWFS show on July 24th-27th (Booth #8400). Plan to stop by and check it out, or click the button below to request a personal consultation on how we can help improve your production process.

|

Please click the "Request a Consultation" link above or give us a call at 1-800-533-6901 and we will sit down and show you how all this happens, in detail. |