We love seeing our team members build long term careers here at Thermwood. Today we are proud to share two exciting promotions that go hand in hand.

Thermwood Promotes Jacob Zellers to Account Manager

Jacob Zellers has been promoted to Account Manager within our Machining Products Division. For the last three years, Jacob did a fantastic job serving as our Trade Show Coordinator.

In his new role, he will oversee sales and dealer relationships across half the United States. Jacob brings a practical understanding of our products to this position, having started his career with us in the Electrical Department.

Outside of work, Jacob resides in Tell City with his wife Brooke and their two daughters.

Thermwood Promotes Chase Frye to Trade Show Coordinator

With Jacob moving into sales, Chase Frye is stepping up to fill his shoes as our new Trade Show Coordinator in the Marketing Department. Chase will take over the execution and logistics for all of our trade show events and exhibitions.

Like Jacob, Chase brings a valuable hands-on perspective to his new role, having started his Thermwood career in the Paint Department. We also want to recognize Chase for his dedication to the community, where he serves as a volunteer firefighter for Anderson Township and a reserve police officer in Cannelton.

It is always a proud moment for us to promote from within, especially when it involves two individuals who work so hard for our company and our customers. Please join us in congratulating Jacob and Chase on their new roles!

About Thermwood Corporation

Founded in the late 1960s, Thermwood Corporation was the first U.S. company to design and build CNC routers and remains a global leader in CNC machining and advanced manufacturing.

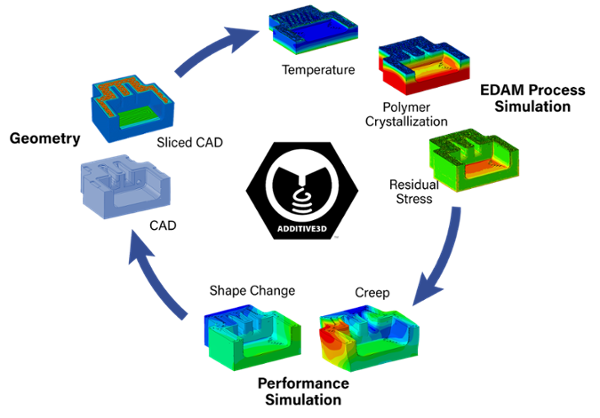

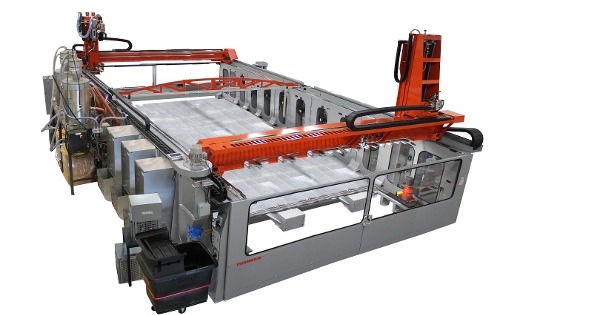

In addition to its broad line of CNC systems, Thermwood is the recognized technology leader in Large Scale Additive Manufacturing (LSAM), offering some of the world’s largest hybrid 3D printing systems. Operating from its 175,000-square-foot facility in Dale, Indiana, Thermwood unites innovation, engineering, and U.S.-based manufacturing to deliver high-performance solutions across industries including woodworking, aerospace, automotive, and defense.

Thermwood — The Leader in CNC Routers and Large Scale Additive Manufacturing Systems

Cruz Meece – Son of Natalie and Jeff Meece of Huntingburg, IN, and a graduate of Southridge High School.

Cruz Meece – Son of Natalie and Jeff Meece of Huntingburg, IN, and a graduate of Southridge High School.

Olivia Vote – Daughter of Amanda and Nicolas Vote of Newburgh, IN, and a Collegebound AP Scholar graduate of Castle High School.

Olivia Vote – Daughter of Amanda and Nicolas Vote of Newburgh, IN, and a Collegebound AP Scholar graduate of Castle High School.