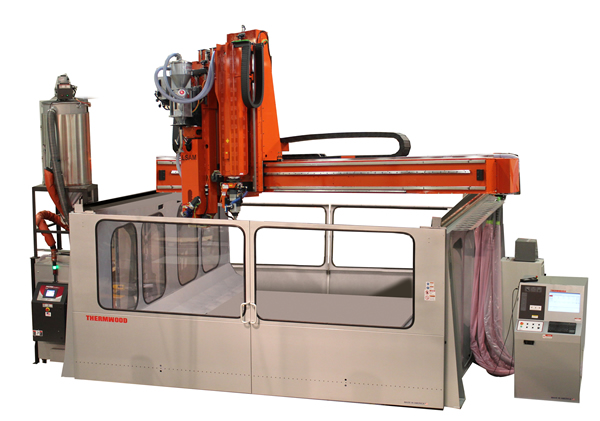

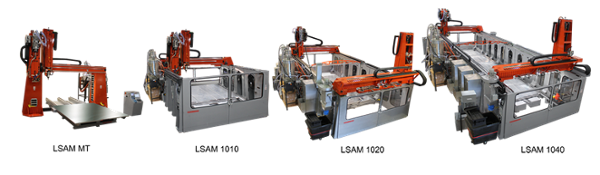

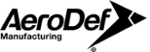

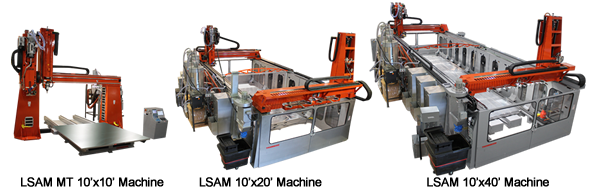

Thermwood recently announced the LSAM MT, a lower cost moving table version of its industry-leading LSAM (large scale additive system). Although Thermwood has hundreds of open moving table CNC routers in operation, similar in configuration to the MT, and believes this configuration will also work for many LSAM customers, several larger customers requested an enclosed machine configuration that is the same size as the MT, but configured like the larger LSAM high wall systems.

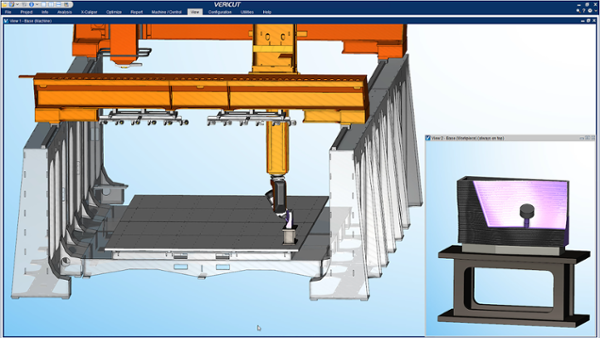

To address this request for a lower cost enclosed machine, Thermwood has announced the LSAM 1010. This system uses the walls from the larger LSAM systems with the gantry, control and sub-systems from the MT.

The new LSAM 1010 has both the print and trim heads on same the gantry just like the LSAM MT.

The Details

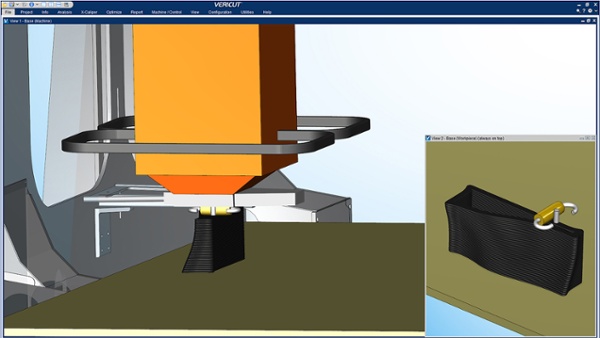

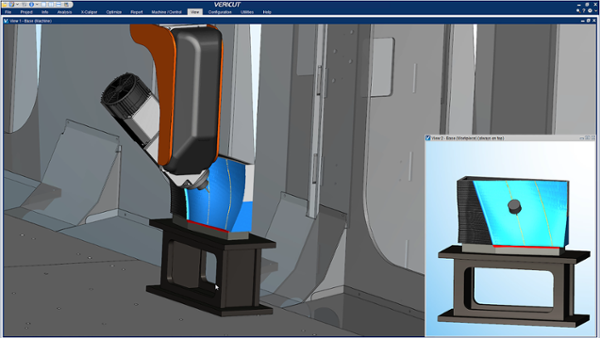

A single moving gantry on the LSAM 1010 carries both the print and trim heads just like on the MT.

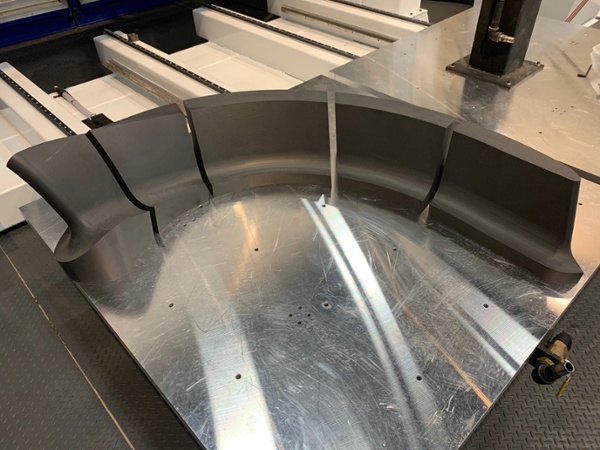

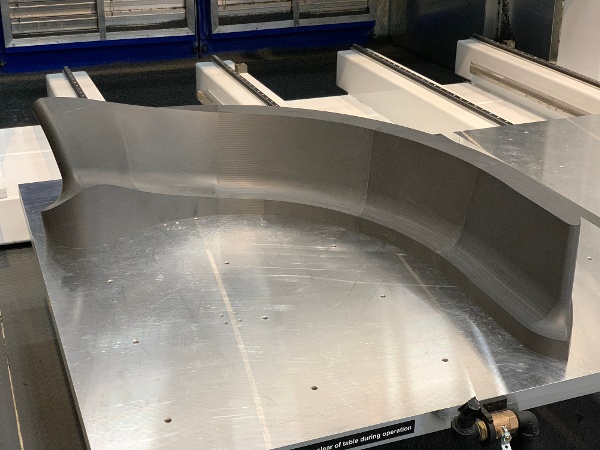

The LSAM 1010 features a fixed 10 foot by 10 foot table. A single moving gantry carries both the print and trim heads as on the MT and, like the MT, it can both print and trim (but not at the same time). The print and trim heads on all Thermwood LSAMs are the same, so all machines can process virtually any reinforced composite thermoplastic materials available today.

The print and trim heads on all Thermwood LSAMs are the same, so all machines can process virtually any reinforced composite thermoplastic materials available today.

Although the LSAM 1010 is slightly higher in price than the MT, it is noticeably less than the larger LSAMs and generally less than the cost and complexity of trying to add an external enclosure to the MT.

In addition, even though the LSAM 1010 is slightly wider than the larger LSAMs (to accommodate mounting both the print and trim heads on the same gantry), the overall footprint of the 1010 is actually slightly smaller than required for the MT. And, like the MT, the 1010 can be purchased as a print only machine.

Thermwood believes that, since it is enclosed like the larger LSAMs, the LSAM 1010 can be built to meet European CE requirements, just like the larger machines.

With the introduction of the LSAM 1010, it is clear that Thermwood is committed to responding to customer requests and providing its industry-leading LSAM additive manufacturing technology in a variety of configurations to better fit varying customer requirements.

About Thermwood Corporation

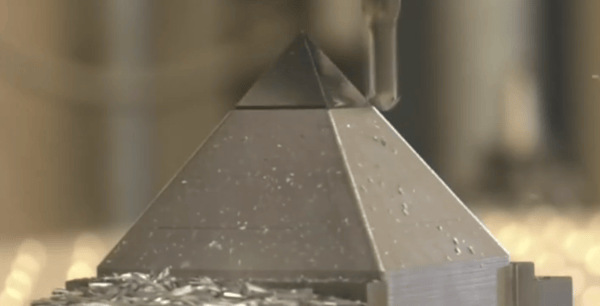

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood has also become the technology and market leader in large scale additive manufacturing systems for thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) machines that both 3D print and trim on the same machine. These are some of the largest and most capable additive manufacturing systems ever produced and are marketed to major companies in the aerospace, marine, automotive and foundry industries as well as military, government and defense contractors.

Aerodef 2020 (March 17th and 18th) in Fort Worth, TX, starts next week, and Thermwood will be there (Booth #615) to talk LSAM (Large Scale Additive Manufacturing).

Aerodef 2020 (March 17th and 18th) in Fort Worth, TX, starts next week, and Thermwood will be there (Booth #615) to talk LSAM (Large Scale Additive Manufacturing).

Thermwood Corporation is pleased to announce the appointment and promotion of Jennifer Watt as its Chief Legal Officer, Secretary and Vice President. In this role, Ms. Watt has oversight of all legal aspects of the company and its corporate governance. Jennifer previously served as Vice President and General Counsel for the company. Prior to joining Thermwood, Jennifer was an Associate with the Indianapolis based law firm of Kroger, Gardis & Regas and the Chicago based law firm of Leo & Weber.

Thermwood Corporation is pleased to announce the appointment and promotion of Jennifer Watt as its Chief Legal Officer, Secretary and Vice President. In this role, Ms. Watt has oversight of all legal aspects of the company and its corporate governance. Jennifer previously served as Vice President and General Counsel for the company. Prior to joining Thermwood, Jennifer was an Associate with the Indianapolis based law firm of Kroger, Gardis & Regas and the Chicago based law firm of Leo & Weber.