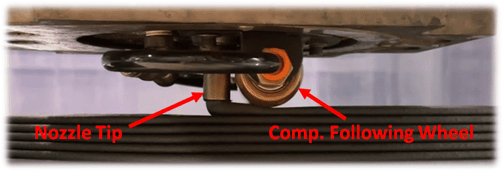

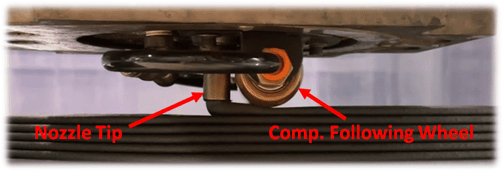

Explore Thermwood's Patented LSAM Chilled Compression Wheel

Posted by Duane Marrett on Wed, Oct 30, 2024

Tags: Additive, LSAM, Additive Manufacturing, Patented, LSAM 1020, High Temperature, Compression Wheel, LFAM, Features

Posted by Duane Marrett on Tue, Oct 29, 2024

Tags: Additive, LSAM, Additive Manufacturing, Patented, Melt Core, LSAM 1020, High Temperature, LFAM, Features

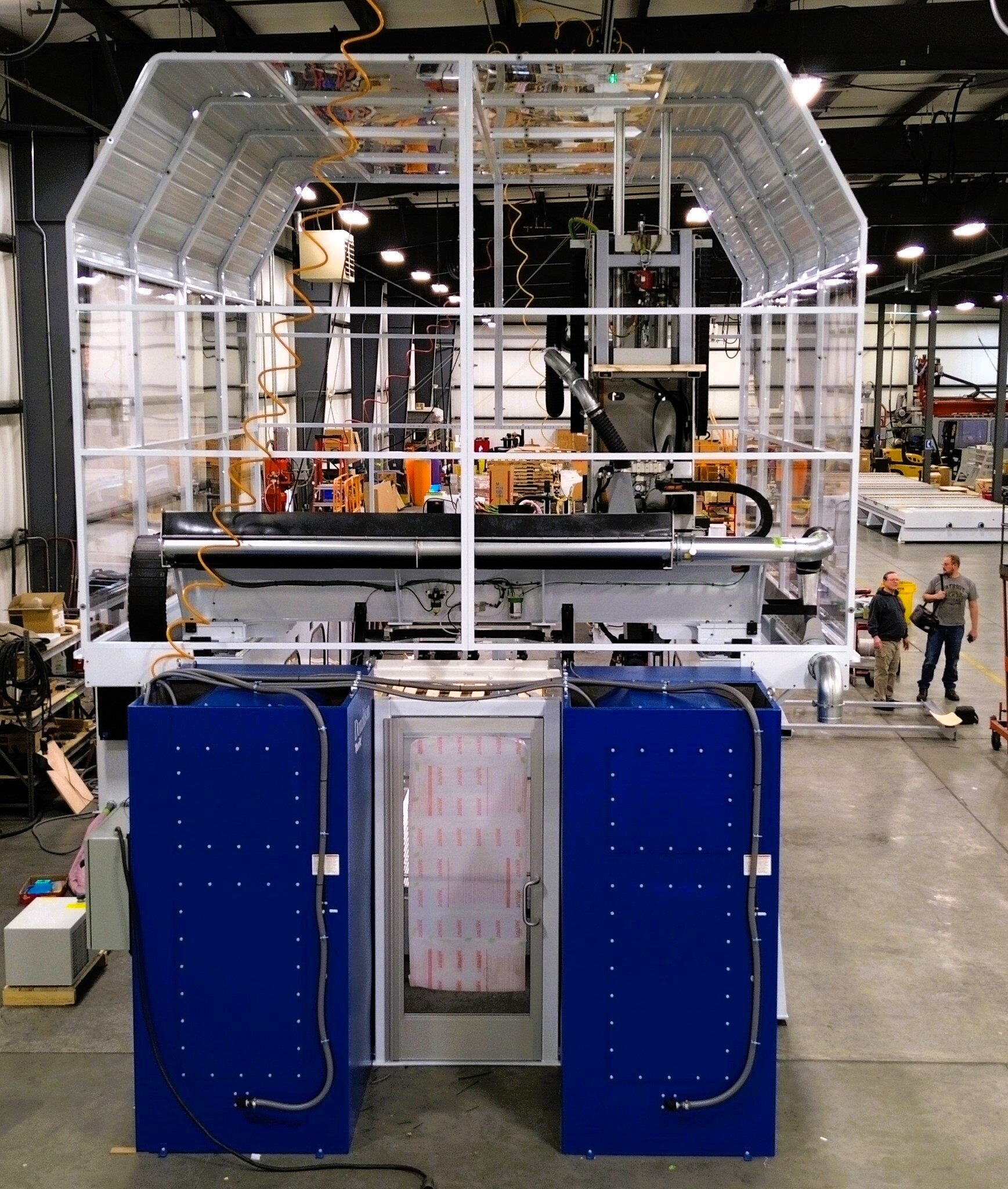

Thermwood has been pioneering Large Format Additive Manufacturing (LFAM) since 2016, leading the industry with our advanced LSAM systems. These machines offer more than just large-scale capabilities—they deliver an unmatched printing experience with superior print consistency, precise temperature control, and powerful slicing software.

In this series, we’ll take you through the exclusive benefits of LSAM technology, starting with our patented Melt Core System. Discover how this cutting-edge innovation redefines material processing to achieve faster, more reliable, and efficient large-scale 3D printing. Ready to explore the future of manufacturing? Dive in and see why Thermwood is the leader in LFAM!

Posted by Duane Marrett on Fri, Oct 25, 2024

Tags: Demonstrations, Additive, LSAM, Additive Manufacturing, LSAM 1020, High Temperature, LFAM, ST Engineering

Posted by Duane Marrett on Wed, Oct 23, 2024

Tags: Video, Additive, Additive Manufacturing, CLA, Cut Layer Additive

Ever wondered how you can produce large format, near-net-shape parts faster and more affordably? Check out this innovative use of Thermwood’s Cut Layer Additive process in action!

Watch as CLA creates a Trim and Drill Vacuum Fixture using RAKU Tool SB-0497 with remarkable precision and speed. This method slashes production costs while maintaining top-quality results. See how cutting layers, rather than printing them, is making large-scale manufacturing easier and more efficient than ever

Project Details:

Cut Layer Additive is a powerful new additive approach that produces large format, near-net-shape parts at incredibly low cost, using a lower cost additive machine. Unlike large format additive printers (like Thermwood’s LSAM), the new process makes large parts from a variety of materials that can’t be printed.

Cut Layer Additive parts are similar to large additively printed parts, in that they are essentially hollow structures made in layers. However, instead of printing the layers, they are instead cut from thick sheets.

Posted by Duane Marrett on Thu, Oct 17, 2024

Tags: Thermwood, New, cabinets, Product Information, Furniture, MDF doors, CabinetShop 43, CabinetShop 43 Nested Based Work Cell

This all-new system is an advanced, fully-integrated nested-based CNC work cell designed to meet the needs of custom cabinet, closet and furniture builders. This complete solution includes an automatic off-load conveyor and a manual assist load system, ideal for producing custom cabinet and closet boxes, drawer boxes, doors and drawer fronts.

|

|

|

What Makes It Special: Learn More

Manual Lift Assist System:

Remote Operator Station:

Heavy-Duty Spindle & Tool Changer:

Machining & Off-loading Process:

Ultra 6 SuperControl:

The CabinetShop 43-512-10 CNC Work Cell is engineered to optimize productivity, precision, and ease of use, making it an essential asset for custom cabinet and furniture manufacturing. CabinetShop 43 512-10 Nested Based Work Cell |

Posted by Duane Marrett on Wed, Sep 18, 2024

Tags: Thermwood, Trade Shows, IMTS, LSAM, LSAM Additive Printers, LSAM AP, CLA, 2024, Recap

Highlights from the recent IMTS show held in Chicago!

It was a pleasure to showcase our innovative technologies, including the LSAM (Large Scale Additive Manufacturing) Additive Printer 510, which printed live, high-temperature (350°F) autoclave-capable aerospace tooling throughout the event!

Each day, we featured a different high-temperature material from leading 3DP material providers. Two tools were printed daily, each tool weighing 215 lbs and printed in 5 hours.

Posted by Duane Marrett on Thu, Aug 08, 2024

Tags: Thermwood, Trade Shows, Model 45, Cut Ready, Cut Center, IWF, CabinetShop 43, CLA, 2024, Nested Based Work Cell, Recap

Highlights from Day 2 of IWF 2024! During the show, we are celebrating 55 incredible years in business with 𝗲𝘅𝗰𝗹𝘂𝘀𝗶𝘃𝗲 𝘀𝗵𝗼𝘄 𝘀𝗽𝗲𝗰𝗶𝗮𝗹𝘀 and live demos of four groundbreaking systems!

Posted by Duane Marrett on Wed, Aug 07, 2024

Tags: Thermwood, Trade Shows, Model 45, Cut Ready, Cut Center, IWF, CabinetShop 43, CLA, 2024, Nested Based Work Cell, Recap

The energy was electric in Thermwood booth B6410 during Day 1 of IWF 2024! During the show, we are celebrating 55 incredible years in business with 𝗲𝘅𝗰𝗹𝘂𝘀𝗶𝘃𝗲 𝘀𝗵𝗼𝘄 𝘀𝗽𝗲𝗰𝗶𝗮𝗹𝘀 and live demos of four groundbreaking systems!

Posted by Duane Marrett on Fri, Jul 12, 2024

Tags: Demonstrations, LSAM, Naval Surface Warfare, LSAM 1020

Posted by Duane Marrett on Wed, Jul 10, 2024

Tags: 5 Axis, Announcements, Model 77, Shipping Machines

© Thermwood Corporation. All Rights Reserved