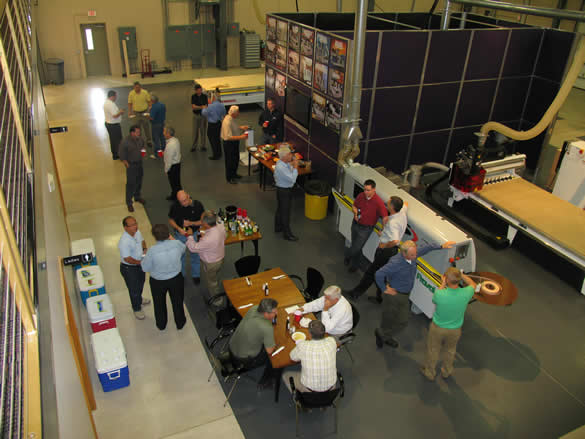

We recently held our 2012 Dealer Conference at our headquarters in Dale, IN. The purpose of this annual event is to get all of our domestic and international dealers together in round-table informative sessions to discuss sales strategies and also to present the exciting changes and new products we plan to release in the next year.

Of course, the conference isn't all work and no play! It also gives everyone a chance to socialize and catch up on news, as well as the opportunity to award our top sellers special prizes at an awards dinner.

This year, our top dealership was Tech Con. Second and third places went to SKF Enterprises and CNC Automation out of Canada. The award for the dealership with the Most Improved Sales for 2011 went to Process and Production Equipment. The award for top International Sales went to Tervelli out of Turkey. Congratulations, guys!

Pictured above are: (front row l-r) Kevin Varwig (Process and Production Equipment), Glenn Suss (Tech Con), Bob Law (CNC Automation), Dave White (SKF Enterprises) Dennis Palmer (VP Sales for Thermwood); (second row l-r) Jason Susnjara (VP Marketing for Thermwood) and Robert Vollmer (Tech Con).

Pictured above are: (l-r) Jan Olinger (International Sales Account Manager) and Mengu Arslanoglu (Tervelli).

Thermwood personnel, domestic and international dealers socialize after hours during the 2012 Dealer Conference.