20-20 Technologies and Thermwood Corporation have joined together to offer a smoothly integrated, highly productive manufacturing system for cabinet manufacturers.

"We are very excited about this new partnership," said Ken Susnjara, CEO of Thermwood. "This represents a truly comprehensive approach from design and retail all the way through manufacturing, all working together smoothly and seamlessly. It combines the best technology of both Companies to create an industry-leading offering."

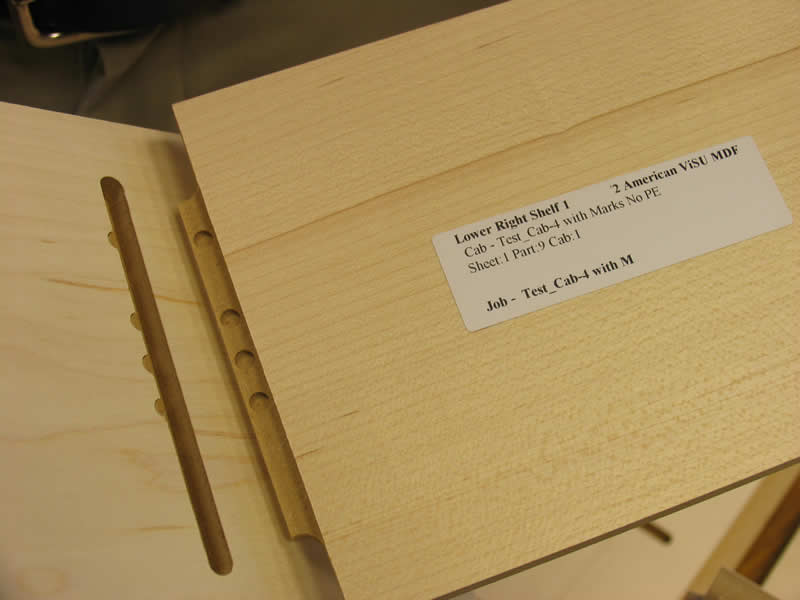

The data process starts with the design. Over 50,000 dealers use 20-20 Design or ShopWare CAD to layout and sell projects. To machine a job, an output file from 20-20 software is sent directly to a Thermwood CNC router and the advanced CNC control on the Thermwood system automatically performs all required CAD functions, nests the parts, prints nest diagrams and labels and runs the job directly from full sheets of material. For even higher production volume, rectangular panels without additional machining are sent to an optimized panel saw, and only parts that require CNC machining are sent to the router. This not only increases overall production capacity, but represents an increase in productivity as well.

"The advantages to using nested based techniques for machining instead of cutting all panels on a saw and then processing machined parts one at a time on a machining center are significant," said Craig Yamauchi, Executive Vice-President of Manufacturing & Residential Solutions of 20-20 Technologies. "Labor requirements are less and productivity is higher, sometimes substantially higher."

20-20 welcomes the opportunity to demonstrate the ease of use and high functionality delivered by this partnership for shops seeking best practices and robust integration at this year's AWFS show in July. 20-20 representatives will be on site to show how you can go from the showroom to the shipping dock with greater sales tools, lower costs, fewer errors and increased ROI.

![]()

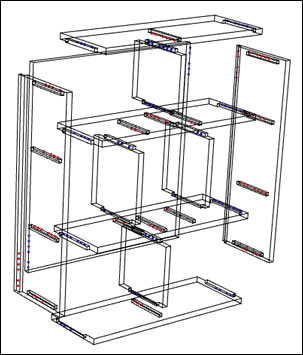

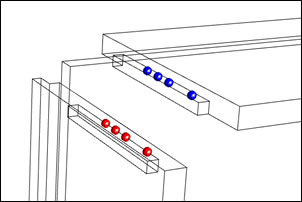

Another even more significant productivity improvement involves actually putting the cabinets together. Simple cabinets are not all that difficult to assemble so major productivity improvement is not likely but as the cabinet design becomes more complex, major productivity improvements are possible. Once fixed partitions, shelves or other features are added to a cabinet, determining exactly how to assemble the parts can become difficult. Generally you must create and print assembly drawings and even with these drawings, the process of sorting out the structure can take significant time.

Another even more significant productivity improvement involves actually putting the cabinets together. Simple cabinets are not all that difficult to assemble so major productivity improvement is not likely but as the cabinet design becomes more complex, major productivity improvements are possible. Once fixed partitions, shelves or other features are added to a cabinet, determining exactly how to assemble the parts can become difficult. Generally you must create and print assembly drawings and even with these drawings, the process of sorting out the structure can take significant time.  So when looking for productivity improvements from CNC routers look to the supporting or peripheral processes and the impact you could have on downstream processes. Right now, today, that’s where the greatest return can be found.

So when looking for productivity improvements from CNC routers look to the supporting or peripheral processes and the impact you could have on downstream processes. Right now, today, that’s where the greatest return can be found.