Happy Holidays from Thermwood

Posted by Jason Susnjara on Fri, Dec 21, 2012

Tags: Thermwood, CNC Routers, CNC Router, Happy Holiday, Prosperous New Year

Before Purchasing Used, Consider a Thermwood Refurbished CNC Router

Posted by Duane Marrett on Fri, Dec 07, 2012

Tags: 3 Axis, 5 Axis, CNC Router, Refurbished, Used, Pre-Owned

Thermwood's CNC Router Refurbishment Program:

Thermwood Corporation’s Technical Service division has an ongoing machine refurbishment program that offers high-quality refurbished Thermwood CNC Routers at affordable prices. These machines are purchased by Thermwood and brought back to our facility for a complete refurbishment process.

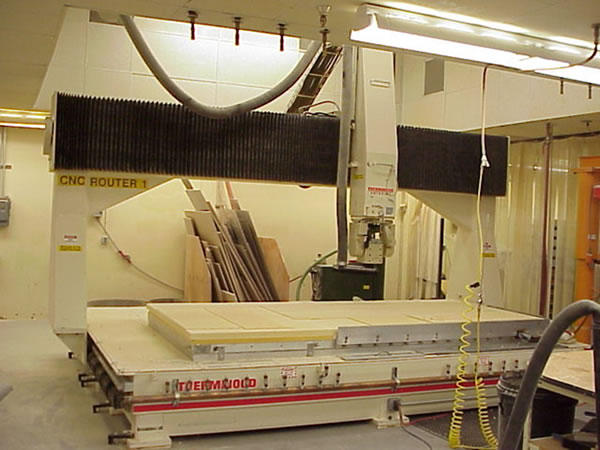

3 Axis CNC Router BEFORE Thermwood Refurbishment

3 Axis CNC Router AFTER Thermwood Refurbishment

5 Axis CNC Router BEFORE Thermwood Refurbishment

5 Axis CNC Router AFTER Thermwood Refurbishment

Bring Your Used Machine up to Modern Standards:

This procedure not only applies to Thermwood owned machines, but also to customer-owned machines to bring them up to today’s standards.

Thermwood Refurbished Machine - What Do You Get?

Every one of these machines has been completely refurbished by Thermwood Corporation. They have been completely disassembled, sand blasted, painted and re-assembled back to new machine specifications. All components have been inspected and either refurbished or replaced with new components. Once the machine refurbishment process was completed, the machines went through the same quality control testing as a new machine. The machine has a 1-year parts and labor warranty.

Here are just a few of things that are typically replaced during the refurbishment process (these are valuable upgrades that you will not receive when purchasing a used machine from an after-market dealer):

-

Machine Worktable

-

Spindle

-

Wiring

-

Power Track

-

Servo Drives

-

Control System.

All Refurbished Thermwood CNC Routers undergo an extensive process:

Step 1: Machine stripped down to base metal

Step 2: Machine gantry primed for paint

Step 3: Machine base primed for paint

Step 4: Machine gantry painted

Step 5: Machine base painted

Step 6: Repainted machine re-assembled and wired

Step 7: New Thermwood SuperControl added

Step 8: New spindle installed

Step 9: Optional equipment installed

Step 9: Vacuum plumbing added

Step 10: New table tops added

Step 11: Finishing touches added

Step 12: Completed machine!

Why buy a Thermwood Factory Refurbished Machine instead of a used CNC Router:

-

You’re buying a machine that has been factory-dissembled, re-assembled and inspected.

-

Any components that do not meet factory specifications are replaced, if there is any question of a component’s integrity, it is replaced.

-

All Refurbished machines come with a full factory warranty - This warranty is one-year parts and labor.

-

You are getting a machine that has been enhanced with the new Thermwood SuperControl with the latest version of Windows technology. This is the same control that ships with new machines, and is designed from its very core to operate a CNC Router with efficiency and higher productivity. It is a fully multitasking control utilizing an Intel® Core™ 5th Generation Six Core Processor. It features a high level of hardware integration, extensive use of reliable surface mount technology and a built in upgrade path for future technology.

-

You are buying a machine that includes a full 5-day operators training course located at Thermwood Corporation in Dale, Indiana.

-

You are not buying someone else’s problems caused by neglect, as can be the case with buying a used machine from another source. These machines are fully disassembled, painted and reassembled back to new machine factory standards.

-

These machines go through a complete quality control inspection to insure each machine meets factory specifications before they leave the factory.

-

A full technical service division for service and parts supports all Thermwood Refurbished machines. This includes Free Lifetime Phone and Forum Support, the ability to upgrade in the future, and support with program questions for your specific machine. One year of Advanced Support (including Virtual Service) is standard with all refurbished machines.

-

You may also choose to list your company with our Free Production Sharing Service.

Thermwood to show Model 77 at JEC Americas Trade Show

Posted by Duane Marrett on Tue, Nov 06, 2012

Tags: Thermwood, Composites, 5 Axis, Announcements, Trade Shows, CNC Router, aerospace, Model 77, JEC Americas

![]()

Thermwood would like to invite you to visit us at the JEC Americas Trade Show in Boston, MA.

When: Wednesday November 7th to Friday November 9th

Where: Boston Convention and Exhibition Center -Booth #E14 We are exhibiting the latest Thermwood equipment:- Featuring our newest 5 Axis CNC Router - the Thermwood Model 77.

We are exhibiting the latest Thermwood equipment:- Featuring our newest 5 Axis CNC Router - the Thermwood Model 77.

For a limited time, you can receive a FREE Visitor's Badge to attend the show free of charge - act now to take advantage of this offer!

About the Model 77 CNC Machining Center:

About the Model 77 CNC Machining Center:

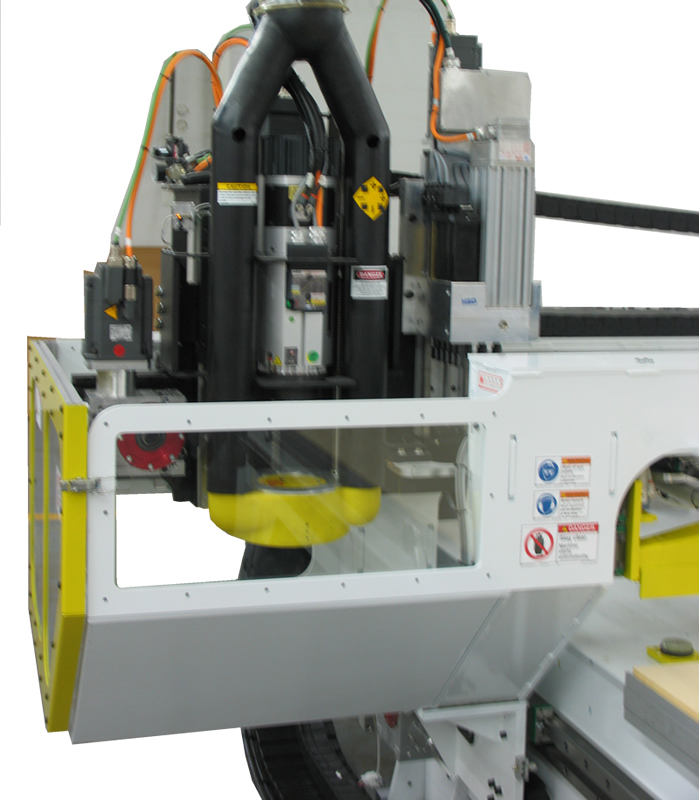

The Thermwood Model 77 5x10 (larger sizes are available) is a heavy duty five-axis CNC router specifically developed for three dimensional machining. This stationary table high wall machine was designed using advanced 3D software utilizing Finite Element Analysis. All major welds including the base and gantry are stress relieved to provide long term stability. This machine is inspected and calibrated utilizing a precision volumetric laser system.

Features:

• 12 HP (3,000-24,000 RPM) Spindle

• Impact Resistant 5 Axis Head

• 10 Position Rotary Tool Change System

• Rapid Speed: 3500 inches per minute

• Moving Gantry

• QCore SuperControl

• Siemens Intelligent Servo Drives Throughout

• Volumetric 3D Laser Compensated Axis Alignment

• Automatic Tool Length Sensor

• Machine Training and Installation

• Free Lifetime Phone/Forum Support

More information can be found here

Thermwood Model 77 5 Axis CNC Machining Center

Posted by Duane Marrett on Fri, Oct 26, 2012

Tags: Thermwood, Composites, 5 Axis, Announcements, CNC Router, aerospace, Model 77, Product Information, 3-D volumetric compensation, Continuous C-Axis Rotation

The Thermwood Model 77 5x10 (larger sizes are available) is a heavy duty five-axis CNC router specifically developed for three dimensional machining. This stationary table high wall machine was designed using advanced 3D software utilizing Finite Element Analysis. All major welds including the base and gantry are stress relieved to provide long term stability. This machine is inspected and calibrated utilizing a precision volumetric laser system.

Features:

• 12 HP (3,000-24,000 RPM) Spindle

• Impact Resistant 5 Axis Head

• 10 Position Rotary Tool Change System

• Rapid Speed: 3500 inches per minute

• Moving Gantry

• QCore SuperControl

• Siemens Intelligent Servo Drives Throughout

• Volumetric 3D Laser Compensated Axis Alignment

• Automatic Tool Length Sensor

• Machine Training and Installation

• Free Lifetime Phone/Forum Support

More information can be found here

Thermwood adds “Personal Pause Button” to YouBuild

Posted by Duane Marrett on Fri, Oct 05, 2012

Tags: Thermwood, Announcements, CNC Router, YouBuild, Personal Pause Button, Remote Control

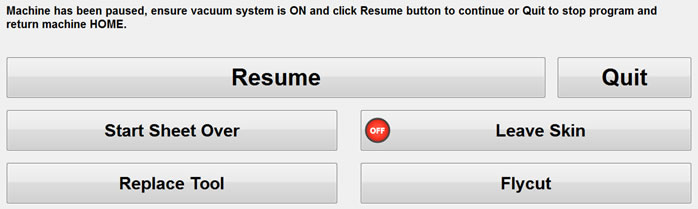

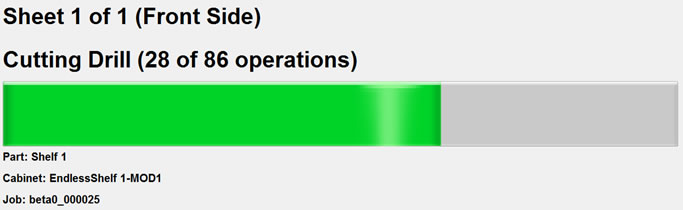

Thermwood has added a “Personal Pause Button” to its CNC routers that process YouBuild programs, which dramatically improves productivity.

Even though modern CNC machines rarely encounter production problems, they do happen. This means the machine operator must remain near the control to stop the machine should something unexpected occur. This limits what he or she can do, other than watch the machine.

To address this, Thermwood has developed a remote wireless “Pause Button” which can be clipped to a belt or pocket. Pressing this button stops the machine, much like an emergency stop, but this is different. The Pause Button, which works at distances of 100 feet or more, not only stops the machine in place but also offers several options for recovery:

-

Back at the control screen, the system wants to know what happened and offers several options. You can just resume cutting by pressing “Resume”. Press the “Replace Tool” button and the machine drops off the tool holder with the broken tool and moves out of the way. Change the bit and replace the tool holder and tell the system to resume. It picks up the new tool, measures it and begins re-cutting the path for the broken tool.

-

Perhaps parts are moving because you didn’t fly cut the table soon enough. By selecting “Leave Skin”, you can continue machining this sheet while leaving a skin on all remaining parts so they won’t move. You do have to remove the skin from these parts later but that is a lot easier and less expensive than remaking parts. When the sheet is done you can fly cut the table right in the middle of the program and then continue with the next sheet.

-

Another possibility is that you encounter bad material or something else happened that makes this sheet unusable. Simply select “Start Sheet Over” and the system will return to Home and instruct you to replace the sheet. It will then re-cut that sheet and continue on. There is a process for pretty much anything that might happen and it all starts with the Pause Button.

Because the Pause button is remote, the operator can move away from the control to sort, label or edge band parts and still be able to stop the machine if something happens. The control even displays a large progress bar along the top of the screen which can be seen from some distance away. It is like the ones you see on your computer and tells you how much time is left before the operator needs to flip a sheet or remove finished parts. By the way, in YouBuild, all back side machining is done on the full sheet rather than one part at a time. It’s a lot faster.

If there is more than one person working in the cell, each can have their own Personal Pause Button.

Personal Pause Button, a simple elegant addition makes processing YouBuild jobs so much easier and more productive.

You can find more information in the YouBuild section of the eCabinet Systems web site and at youbuild.com.

Thermwood AutoProcessor 5×10

Posted by Duane Marrett on Tue, Aug 21, 2012

Tags: Thermwood, CNC, Woodworking, Nested Base, 3 Axis, Announcements, Trade Shows, Point of Purchase, CNC Router, High Performance, cabinets, QCore, closets, Furniture, IWF, AutoProcessor, architectural, millwork

Thermwood's latest machine, the AutoProcessor 5x10 - Shown at the 2012 IWF show in Atlanta, GA Booth #5753.

The AutoProcessor 5×10 is a complete solution for Nested Based Panel Processing, Cabinet/Closets, Marine/Boat Building, Furniture Manufacturing, Exhibits/ Store Fixtures, Machining Plastic Sheets and High Volume Cabinet Production.

With each cycle, the machine first labels the sheet, positions the sheet on the table, machines the material, off-loads the finished parts and then repeats the process. Dust collection during this process keeps scrap and debris to a minimum. Labels help the operator to quickly sort the parts, and Assembly Marks help final assembly happen quickly and easily.

Features:

Features:

• Thermwood QCore SuperControl

•5’ x 10’ Working Table / Moving Gantry

• Rapid Speed 4,200 IPM

• 4000 lb. Lift Table for Loading

• 12 HP HSK Electro-Spindle

• 8 Position Tool Changer

• Automatic Pop-Up Pins

• Automatic Tool Sensor

• Automatic CNC Labeler

• 9 Spindle Drill Bank

• Unload Table

More information can be found here

Thermwood Announces “YouBuild” Program to Cabinetmakers

Posted by Jason Susnjara on Mon, Jul 16, 2012

Tags: Thermwood, Woodworking, Announcements, CNC Router, cabinets, nested based, closets, manufacturing, Furniture, YouBuild, US made

Thermwood Announces “YouBuild”

Bringing Furniture Business to Cabinetmakers

Thermwood Corporation has announced a new program called “YouBuild”, a new and unique business model, providing an easy path for cabinetmakers with Thermwood CNC routers to easily address the huge home and office furniture market.

It starts with a web site, YouBuild.com, which offers over a thousand unique designs for home and office furniture and closets, some by renowned furniture designers. What makes this even more unique is that these designs can be customized and are available in four real wood species, walnut, maple, oak and cherry, either finished or unfinished. Sizes of most items can be adjusted. The wood, specially made for YouBuild by Columbia Forest Products, the largest manufacturer of hardwood plywood in North America, is high-quality, formaldehyde-free and available in any quantity through local Home Depot stores under a special order program.

Manufacturing is done locally by cabinet shops who participate in YouBuild, called “YouBuild Cut Centers”. Orders are placed online. Each Cut Center has its own online area within the YouBuild site. Products are specified, customized and quoted online. YouBuild Cut Centers access CNC programs online, using their CNC machined control, and then cut and edgeband parts that were ordered. Customers can assemble themselves, using unique joinery, or they can have the Cut Center assemble for them.

Cut Centers are not required to do any design or programming, they just sell and make what is ordered using the online programs. To help sell, they can establish Retail Dealers and Retail Design Centers. These are independent individuals and businesses that promote and sell YouBuild products for them and receive a commission on any orders they generate.

YouBuild offers an entirely new approach to furniture and, because the program is so simple and efficient, top-quality, formaldehyde-free, real hardwood materials can be used, while keeping prices highly competitive. There is no cost to become a YouBuild Cut Center as long as shops have the equipment necessary to use the technology. You can find more information in the YouBuild section of the eCabinet Systems web site and at YouBuild.com.

CNC Router Training at Thermwood

Posted by Duane Marrett on Fri, Jun 08, 2012

Tags: CNC, CNC Routers, 3 Axis, 5 Axis, CNC Router, Training, education, Customer Lounge

When you purchase a CNC Router from Thermwood, a five-day comprehensive programming/operation training course for two students is included. This course is conducted at Thermwood's state of the art Dale, IN facility.

Superior Factory Training:

Training at Thermwood is conducted in a modern, comfortable and well equipped center devoted specifically to educating our customers. This is, by far, the fastest and most efficient way to learn. Over the years, Thermwood has experienced the ups and downs of training at the customer's facility, the interruptions and distractions, not to mention the lack of classroom facilities and equipment. It just doesn’t work very well. At Thermwood, the atmosphere contributes to the learning experience. Each classroom is setup specifically for the course being taught.

Training at Thermwood is conducted in a modern, comfortable and well equipped center devoted specifically to educating our customers. This is, by far, the fastest and most efficient way to learn. Over the years, Thermwood has experienced the ups and downs of training at the customer's facility, the interruptions and distractions, not to mention the lack of classroom facilities and equipment. It just doesn’t work very well. At Thermwood, the atmosphere contributes to the learning experience. Each classroom is setup specifically for the course being taught.

Training Facilities: Our machine operator/programmer courses are located adjacent to the machine training lab, where students complete the prescribed projects on a specific training machine utilized only for training purposes. Our application software classes are conducted in a classroom with state-of-art computer equipment. Then when it comes time for practical applications on a full sized machine, Thermwood's training lab is equipped with a CabinetShop 45 outfitted with all major options and features. Real production type parts are cut. What a confidence builder!

Our machine operator/programmer courses are located adjacent to the machine training lab, where students complete the prescribed projects on a specific training machine utilized only for training purposes. Our application software classes are conducted in a classroom with state-of-art computer equipment. Then when it comes time for practical applications on a full sized machine, Thermwood's training lab is equipped with a CabinetShop 45 outfitted with all major options and features. Real production type parts are cut. What a confidence builder!

Customer Training Lounge:

Thermwood also has a customer lounge and workstation available for use during your training at our facility. This comfortable area features free:

Thermwood also has a customer lounge and workstation available for use during your training at our facility. This comfortable area features free:

- Wi-Fi

- Phones

- Daily Lunch

- Snacks

- Drinks

- Lounge area with plenty of seating and satellite-equipped large flat-screen tv for your use.

Continuing Help and Support

Our five-day machine programming/operations training here at Thermwood is the first step to helping you hit the ground running. The goal is to help you understand how to utilize the power of your Thermwood CNC Router and QCore SuperControl to make your operation as efficient and productive as possible. Our commitment to this doesn't end when you complete the training course. We also offer:

Our five-day machine programming/operations training here at Thermwood is the first step to helping you hit the ground running. The goal is to help you understand how to utilize the power of your Thermwood CNC Router and QCore SuperControl to make your operation as efficient and productive as possible. Our commitment to this doesn't end when you complete the training course. We also offer:

- Free Lifetime Phone Support

- Virtual Service Support (1st year free)

- Free Forum Support

For more information on our machine training or about any of our products, please email us at sales@thermwood.com or give us a call at 1-800-533-6901.

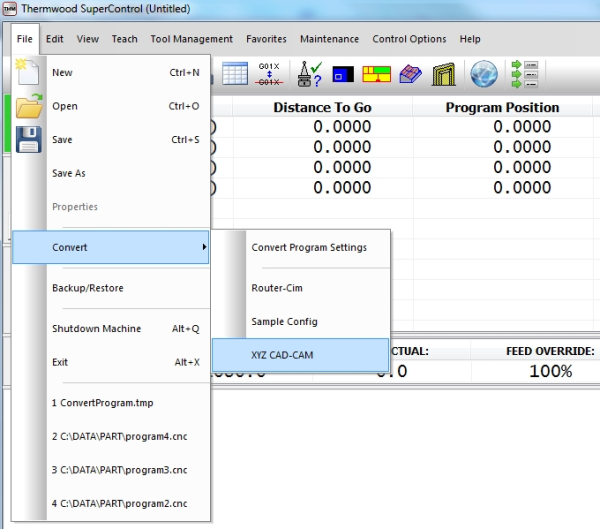

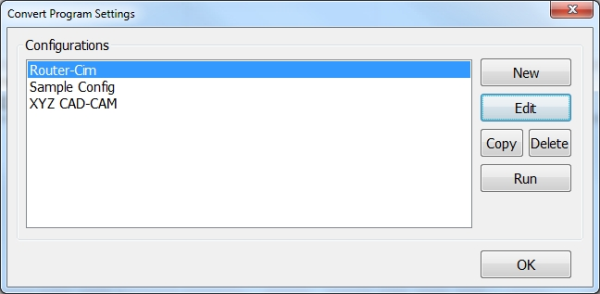

Convert Router-CIM® to M and G code for Thermwood CNC Routers

Posted by Duane Marrett on Thu, Apr 26, 2012

Tags: Thermwood, CNC, CNC Routers, Productivity, 3 Axis, CNC Router, Free, QCore, SuperControl, super controller, Router-CIM, Convert

Thermwood Corporation announces new software developed to convert Router-CIM® programs to standard M and G code language for use on a Thermwood CNC router.

This conversion tool takes place on Thermwood's QCore Super Controller and is very simple to use. You just load the Router-CIM® G code file directly into the QCore controller using the convert option and the M and G code is automatically converted to conform to your Thermwood machine's specs, and is ready to run.

This EIA conversion works not only with Router-CIM® programs but with virtually all other programs that contain standard EIA code, and allows you to use your older, existing Router-CIM® programs with ease.

If you would like more information on this conversion process, or how a free demonstration of how our machines can improve your production process, please contact us.

Thermwood Announces New Model - MTR 30DT

Posted by Jason Susnjara on Fri, Mar 16, 2012

Tags: Thermwood, eCabinet Systems, software, control nesting, 3 Axis, Announcements, CNC Router, QCore, manufacturing, panel processing, MTR 30DT

Thermwood Corporation, a leading US manufacturer of CNC routers, announces the MTR 30DT dual table CNC router for machine paced panel processing.

The MTR30 DT is designed for machining jobs that require multiple tools and dual tables for nonstop machine production. The machine is configured with two stationary 61 inch by 121 inch high flow vacuum tables with dual programmable part locators. It is equipped with a 12 HP spindle with an automatic tool changing system that includes both fixed and at the head tooling; for a total of 20 tool positions for routing. It also includes a drill bank with both horizontal and vertical drills, available up to 25 spindles.

Included within the QCore control is Thermwood’s featured Control Nesting software along with a dxf convertor for accepting dxf files for automatic nesting. The control also includes a huge 1 terabyte hard disk for program storage and is enclosed in a dust protected air conditioned cabinet.

Visit www.thermwood.com or call 800-533-6901 or email info@thermwood.com for more information on this product.

Thermwood is a US company with dealers and distributors worldwide. In addition to machine manufacturing and software development, Thermwood has a technical service organization that provides support, machine installation, training, retrofits, custom programming and production assistance.