See us Live

Posted by Duane Marrett on Tue, Apr 25, 2023

Tags: Thermwood, Video, Thermwood LSAM, VLP, LSAM AP, Fixture

Posted by Duane Marrett on Fri, Apr 14, 2023

Tags: Thermwood, Video, virtual tour, Thermwood LSAM, LSAM MT, LSAM 1020

Thermwood has been the market and technology leader in Large Format Additive Manufacturing (LFAM) since 2016, thanks to our innovative LSAM (Large Scale Additive Manufacturing) systems.

We offer the broadest range of LFAM (Large Format Additive Manufacturing) systems in the industry, to help you find the perfect solution for your needs and budget. But LSAM systems are more than just 3D printers - they're real production systems, capable of producing industrial fixtures, molds (including high temp), tooling, foundry patterns, prototypes and end products from a wide variety of both low and high temp materials.

𝗔 𝗳𝗲𝘄 𝗟𝗦𝗔𝗠 𝗮𝗱𝘃𝗮𝗻𝘁𝗮𝗴𝗲𝘀:

• LSAM systems offer three printing orientations - HLP (Horizontal Layer Printing), VLP (Vertical Layer Printing), allowing parts to be printed that are as long as the machine table and ALP (Angle Layer Printing), the ability to print at a 45 degree angle.

• With the fastest print heads in the industry, our LSAM systems can print at speeds from up to 200lbs per hours to over 500 lbs per hour.

• Choose from Print-only or Print-and-Trim combinations with table sizes ranging from 5’x5’ to 15’x40’ and beyond.

• Save both time and money over traditional methods - case study here: https://bit.ly/3zWoWjk

𝗦𝗲𝗲 𝘂𝘀 𝗹𝗶𝘃𝗲:

We will be at a variety of upcoming shows in the next few weeks, and you can visit to learn more about LSAM.

Check us out next week at SAMPE 2023 in Seattle (booth E10), JECWorld 2023 in Paris starting on April 25th (US Pavilion, Hall 6, booth Q49) and printing live with #SABIC’s LNP™ ELCRIN™ WF006NiQ resin on an LSAM AP 510 at Rapid 2023 in Chicago starting May 2nd (booth #2418).

Don't settle for less when it comes to your production process. Upgrade to Thermwood's LSAM system and take your manufacturing to the next level!

Visit https://bit.ly/3GFE3RR to learn more about LSAM.

LSAM Examples

Posted by Duane Marrett on Fri, Mar 17, 2023

Tags: Thermwood, Video, virtual tour, Thermwood LSAM, Boeing, LSAM 1020, Boeing Auburn, Discovery Education

Posted by Duane Marrett on Wed, Nov 09, 2022

Tags: Thermwood, CNC, 5 Axis, CNC Router, Model 90, Video, Copper

![]()

More Info on the Model 90: https://bit.ly/m90thm

Posted by Duane Marrett on Fri, Nov 04, 2022

Tags: Thermwood, Announcements, Trade Shows, Video, IMTS, Large Scale, Thermwood LSAM, LSAM Additive Printers

More info on LSAM: https://bit.ly/LSAM_INFO

Posted by Duane Marrett on Thu, Oct 13, 2022

Tags: Thermwood, Announcements, Trade Shows, Purdue, Large Scale, Thermwood LSAM, Ascent Aerospace, LSAM Additive Printers, Airtech, CAMX, General Atomics

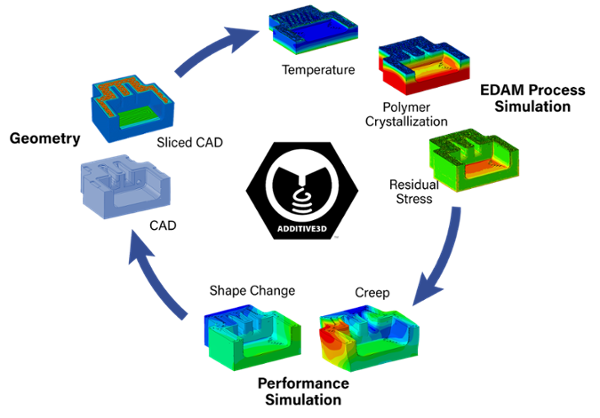

For CAMX 2022 in Anaheim, CA on October 18th-20th, Thermwood will be printing LIVE on an LSAM Additive Printer 510 – two sections of a multi-piece layup tool each day using Airtech Advanced Materials Group Dahltram™ C-250 CF carbon fiber reinforced PC material. LSAM Research Laboratory at Purdue ADDITIVE3D Software will be on display as well, with Purdue representatives on site for demonstrations. We will also have several large customer-created large scale tools on display from Airtech, Ascent Aerospace, General Atomics and more.

This promises to be an exciting demonstration of the LSAM Additive Printer Large Scale Additive System in Booth #W2.

Representatives from the Thermwood Research Laboratory at Purdue University (located in Purdue University's Composites Manufacturing Simulation Center - CSMC) will also be on hand to demonstrate their ADDITVE3D simulation software.

We will be printing two sections of a multi-piece layup tool each day using Airtech Advanced Materials Group Dahltram™ C-250 CF carbon fiber reinforced PC material

The LSAM Additive Printer systems are single gantry, moving table configurations and are available in two table sizes, 5’x5’ and 5’x10’. The 5’x10’ table is available in two configurations, 5’ wide with 10’ of front to back motion and 10’ wide with 5’ of front to back motion. Choice of configuration depends on several factors, fitting it existing factory floor space is one factor.

The specially designed, highly rigid tab and slot, structural steel gantry also incorporates a fume extraction system that pulls print fumes through specially designed activated charcoal filters to remove them and “sweeten” the air.

LSAM additive Printers use the exact same print head mechanism as all the other, including the largest LSAM Systems which means that they produce the same amazing print quality that has made LSAM the leader in large scale additive printing. They also use the same highly advanced Ultra 6 control with all its exclusive, patented print features and capability.

The systems come standard with a single hopper polymer dryer for applications that don’t change print material very often. For installations that print a wider variety of materials, a dual hopper dryer is available as an option.

An enclosure that surrounds the machine is also available. The machine with the full enclosure can also be built to meet European CE standards.

Posted by Duane Marrett on Mon, Aug 08, 2022

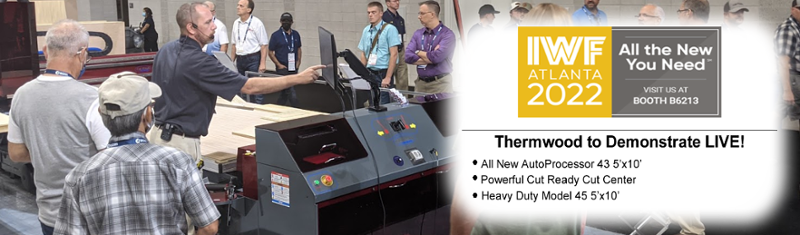

Tags: Thermwood, Trade Shows, Model 45, Cut Ready, Cut Center, Video, IWF, Discount, AutoProcessor 43, 2022

Please Click Here to Register for IWF with 60% off Advanced Registration courtesy of Thermwood, and plan to stop by our booth #B6213 to see our superior technology in action!

For IWF 2022, Thermwood Corporation, an innovator in the design and manufacture of American Made 3 and 5 Axis CNC Routers, is proud to demonstrate three systems. We’ll have our all new AutoProcessor 43 510, our powerful Cut Ready Cut Center and our heavy-duty Model 45 510 machining on site.

The AutoProcessor 43 5'x10' is an all-new complete, nested-based, CNC routing system for machining cabinet boxes, custom furniture and basically any nested type of sheet product.

It is fully automatic from labeling and positioning of the sheets, to machining and off-loading the machined parts.

With each cycle, the machine simultaneously and automatically:

Thermwood will also be demonstrating the award-winning Cut Ready Cut Center. This powerful system helps you quickly and easily create most products a cabinet shop would want to make without a CNC programmer (cabinets, furniture, doors, drawers, moldings, stair stringers and much more). Just tell it what you want to make via a simple touch-screen interface, and it makes it. Or, you can operate it as a traditional CNC router.

Most people can operate it with little or no training or guidance. It is complete, fully contained with all the ancillary equipment smoothly integrated into a package that almost runs itself.

If you build custom cabinets, and want to automate your machining...you really only have two choices. You can do it the easy way…or the hard way.

If you build custom cabinets, and want to automate your machining...you really only have two choices. You can do it the easy way…or the hard way.Designed and engineered in America, the Cut Ready Cut Center is made to simplify and automate your production.

It allows you to remain a cabinet shop, focused on making custom cabinets, instead of a software company, worried about learning difficult and expensive software.

The Cut Center takes care of both the big and small details so you don't have to!

Making product on the Cut Center requires neither a CNC programmer nor a trained machine operator. Pretty much anyone can run a Cut Center, and make anything a cabinet shop might need (cabinets, closets, doors, moldings, stair stringers, furniture...and much more)!

We will also be machining solid wood and aluminum and plywood sheet stock on the Model 45.

The heavy-duty Model 45 is designed for a variety of functions, including the machining of rotary operations when equipped with our optional C-Axis. This expands the capability of this already useful machine to include volutes, carvings, chair parts, stair components and much more.

Posted by Duane Marrett on Wed, Jul 20, 2022

Tags: Thermwood, Trade Shows, Model 45, Cut Ready, Cut Center, Video, IWF, AutoProcessor 43, 2022

For IWF 2022, Thermwood Corporation, an innovator in the design and manufacture of American Made 3 and 5 Axis CNC Routers, is proud to demonstrate three systems. We’ll have our all new AutoProcessor 43 510, our powerful Cut Ready Cut Center and our heavy-duty Model 45 510 machining on site.

The AutoProcessor 43 5'x10' is an all-new complete, nested-based, CNC routing system for machining cabinet boxes, custom furniture and basically any nested type of sheet product.

It is fully automatic from labeling and positioning of the sheets, to machining and off-loading the machined parts.

With each cycle, the machine simultaneously and automatically:

Thermwood will also be demonstrating the award-winning Cut Ready Cut Center. This powerful system helps you quickly and easily create most products a cabinet shop would want to make without a CNC programmer (cabinets, furniture, doors, drawers, moldings, stair stringers and much more). Just tell it what you want to make via a simple touch-screen interface, and it makes it. Or, you can operate it as a traditional CNC router.

Most people can operate it with little or no training or guidance. It is complete, fully contained with all the ancillary equipment smoothly integrated into a package that almost runs itself.

Jody Wilmes (Cut Ready Product Manager) helps you understand the differences between the Cut Center and a regular CNC Router.

Jody provides an in-depth look at what it takes to successfully operate each machine, and lists some of the additional expenses and things to consider when shopping for an automated solution.

We will also be machining solid wood and aluminum and plywood sheet stock on the Model 45.

The heavy-duty Model 45 is designed for a variety of functions, including the machining of rotary operations when equipped with our optional C-Axis. This expands the capability of this already useful machine to include volutes, carvings, chair parts, stair components and much more.

Posted by Duane Marrett on Thu, Jun 16, 2022

Tags: Thermwood, Announcements, Scholarship, 2022

Thermwood is proud to announce that we will be awarding four scholarships to dependents of associates for the Class of 2022. Each recipient will receive a $2,000 renewable scholarship.

Since the introduction of these renewable scholarships, Thermwood has awarded over $200,000 to students wishing to further their education.

Olivia Lopez is the daughter of Daniel and Tena Lopez of Holland, IN. She is a graduate of Southridge High School.

She has been a member of the National Honor Society, Business Professionals of America, Freshman Mentor Program, Christian Motorcyclists Association, and tennis team. She is also passionate about creative writing.

Olivia plans to major in Forensic Science at Maryville University in the fall.

Emma Haefling is the daughter of Paul and Ellen Haefling of Santa Claus, IN. She is a graduate of Heritage Hills High School.

During high school Emma was part of the Beta Club, Student Council, HH Riley’s Dance Marathon, and Volleyball team. She has been awarded the Top 10% of Class, the Captains & Patriot award for Volleyball, Science Fair awards, and Behavioral Science for 2022 Science Bowl.

She plans to major in Biology (Genetics) at Ball State University this fall.

Andrew Meece is the son of Natalie and Jeff Meece of Huntingburg, IN. He is a graduate of Southridge High School.

Andrew Meece is the son of Natalie and Jeff Meece of Huntingburg, IN. He is a graduate of Southridge High School.

He has been a member of the Raider Band and Choir during high school. He is also an active member of the Zoar Methodist Church.

Andrew plans to attend Asbury University to major in Biblical Theology.

Emma Tretter is the daughter of Daniel and Jennifer Vonderheide of Jasper, IN. She is a graduate of Northeast Dubois Jr/Sr High School.

Emma Tretter is the daughter of Daniel and Jennifer Vonderheide of Jasper, IN. She is a graduate of Northeast Dubois Jr/Sr High School.

She plans to major in Design Technology at Ivy Tech Community College Evansville in the fall.

Thermwood would like to congratulate all seniors of the Class of 2022 and wish them the very best in their future studies and endeavors!

Posted by Duane Marrett on Wed, Jun 15, 2022

Tags: Thermwood, tooling, LSAM, Thermwood LSAM, LSAM 1020, Spirit Aerosystems, Additive tooling

It was determined that carbon fiber filled polycarbonate would provide sufficient strength to withstand the significant forces used in the stretch form process, however unlike traditional lubrication methods, Techmer PM blended a new polycarbonate formulation that contained an internal lubricant in addition to the carbon fiber, eliminating the need for any additional lubrication.

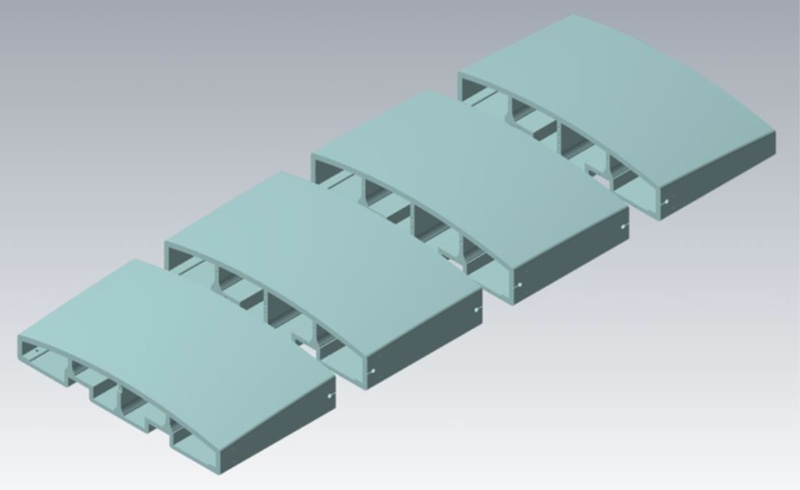

The tool was printed on Thermwood’s LSAM 1020 dual gantry print and trim system. While this machine is equipped with Vertical Layer Printing and could have printed the tool in one piece, because it requires that you to wait for each printed layer to cool enough before adding the next layer, it would have required 58 hours of continuous print time to produce a one-piece tool. Instead they decided to print the part in four sections, two at a time for a total print time of 29 hour and 20 minutes, cutting the print time in half. Printing required 3,613 pounds of material.

The Four Parts Printed

The four parts then needed to be machined and assembled.

Layout of the Assembly

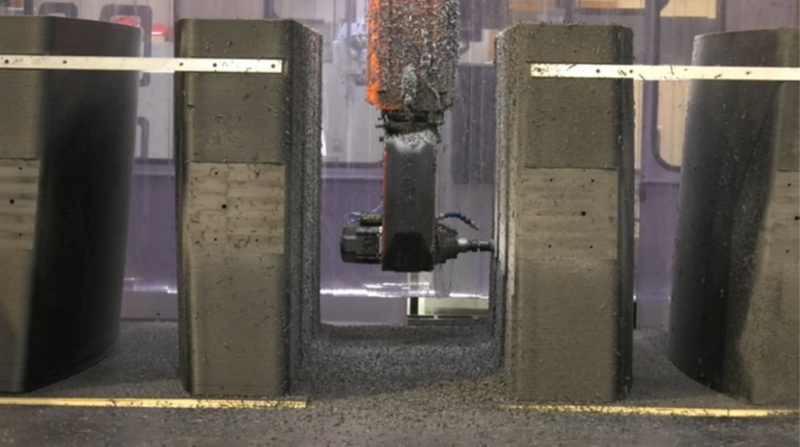

All surfaces of the parts except for the front working surface were then machined in place.

Initial machining. The holes in the center of each side are for center-of-gravity brackets used for part handling during assembly.

The mating faces were then machined flat except for slightly raised bosses which insured proper gapping for the adhesive. Adhesive is only one part of a multi part approach used to permanently and securely attach the parts to each other. These are all highly accurate, precision surfaces.

Flat Face has raised bosses to provide proper adhesive gap

Draw bolt holes and slots were machined into the back of the tool which allow the parts to be bolted together in addition to the adhesive.

Machined area for draw bolts

In addition to adhesive and draw bolts, alignment holes and countersink holes were machined into the center sections of the tool.

The 6-inch long alignment pins for these holes are machined with adhesive channels providing not only alignment between parts but also another level of permanent attachment.

Heavy duty alignment pins offer another attachment layer

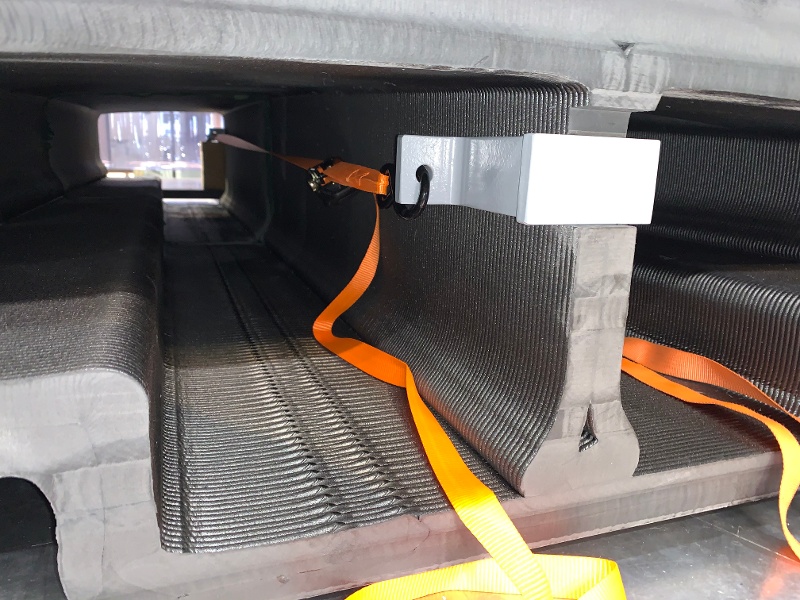

The next level of attachment uses brackets positioned inside the structure near the front surface, which are attached to each other using tensioned aircraft steel cables, securely holding the front surface of the four parts together.

Brackets with temporary straps which were replaced by tensioned steel cables

The parts were then final assembled using another unique approach. Each part is relatively heavy and because of relatively short open time for the adhesive, there is a limited amount of time available during assembly to apply the adhesive and mate the parts securely together. The parts need to be pushed together while aligned, literally within a few thousandths of an inch and need to be mated absolutely even and square. This turned out to be fairly easy using the Vertical Layer Print table mechanism installed on the LSAM machine.

The parts were carefully hand fitted together. Then, one part was attached to the machine table and the other to the mechanism that moves the vertical table. The vertical table drive then moved the parts apart about 20 inches, adhesive was applied and the vertical table mechanism pushed the parts back together again, square and perfectly aligned.

Adhesive being applied to separated pieces

Draw bolts and cables were permanently attached and after the adhesive fully cured, the completed tool front surface was machined to final dimensions using the LSAM trim head. When Spirit AeroSystems measured the final working surface it was within +/- 0.005”, well within their requirements. Total of all machining including the final working surface was 118 hours and 58 minutes.

Front surface measured to within +/- 0.005"

Spirit AeroSystems then stretched 10 skin panels of 0.050” thick 2024 T3 aluminum to 5% elongation. The press controller showed that each jaw gripping the aluminum sheet had ~100 tons of load on it, so ~200 tons in total. Everything was kept under the same conditions as if running a production part and although the printed tool was considerably lighter in weight than their traditional tools, it appeared to perform in a similar manner.

Skin panel being stretched

This is a first step. There are additional tests to be performed and more data to be collected, but it does appear that large 3D printed composite stretch form tools can be produced using currently available material and current equipment, saving considerable time and money and opening yet another application for this exciting new technology.

Spirit AeroSystems is one of the world's largest manufacturers of aerostructures for commercial airplanes, defense platforms, and business/regional jets. Also, Spirit serves the aftermarket for commercial and business regional jets.

Thermwood is a US based, multinational, diversified machinery manufacturer that has become the technology lead in large scale additive manufacturing of thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) systems that both 3D print and trim on the same machine.

© Thermwood Corporation. All Rights Reserved