Thermwood was a key development partner in a Navy ManTech funded program issued to Boeing Research and Technology. The ManTech program was managed by Advanced Technology International (ATI) for the Office of Naval Research (ONR) with funding provided from the Naval Air Systems Command (NAVAIR) Aircraft Equipment Reliability & Maintainability Improvement Program (AERMIP). Fleet Readiness Center East (FRCE) was a key technical contributor for the low cost composite cure tooling technology development.

The Details

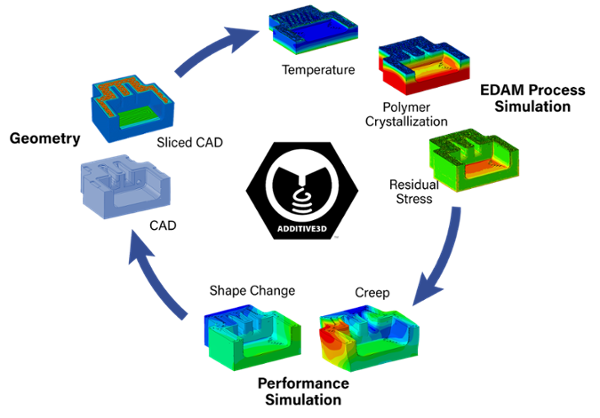

Thermwood’s Large Scale Additive Manufacturing (LSAM) machine was selected as the Large Format Additive Manufacturing (LFAM) machine to conduct the technology development. Several unique equipment features of the LSAM machine drove the selection. The high temperature autoclave cure tooling operating environment of 355 degree Fahrenheit and 85 psi provides a challenge for polymer based tool material. Additional composite cure tooling requirements for vacuum integrity and dimensional stability were validated during the development. Neil Graf Office of Naval Research, noted “Composite manufacturing is a strategic technology for future platforms and development of more cost effective tooling solutions would significantly benefit the implementation.”

The Process

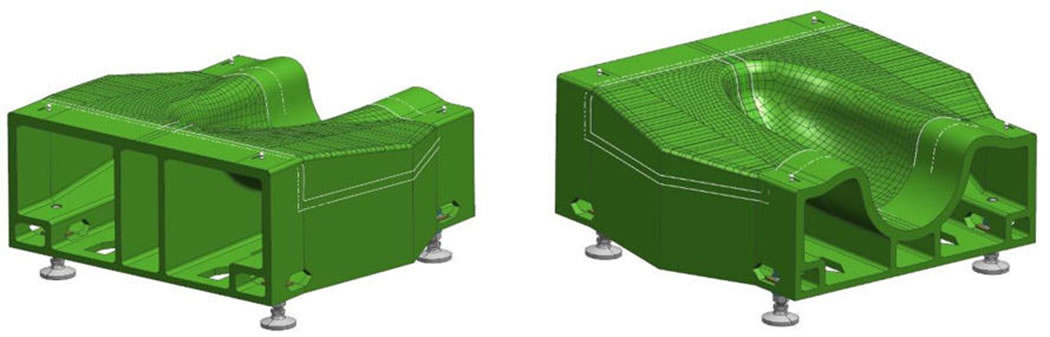

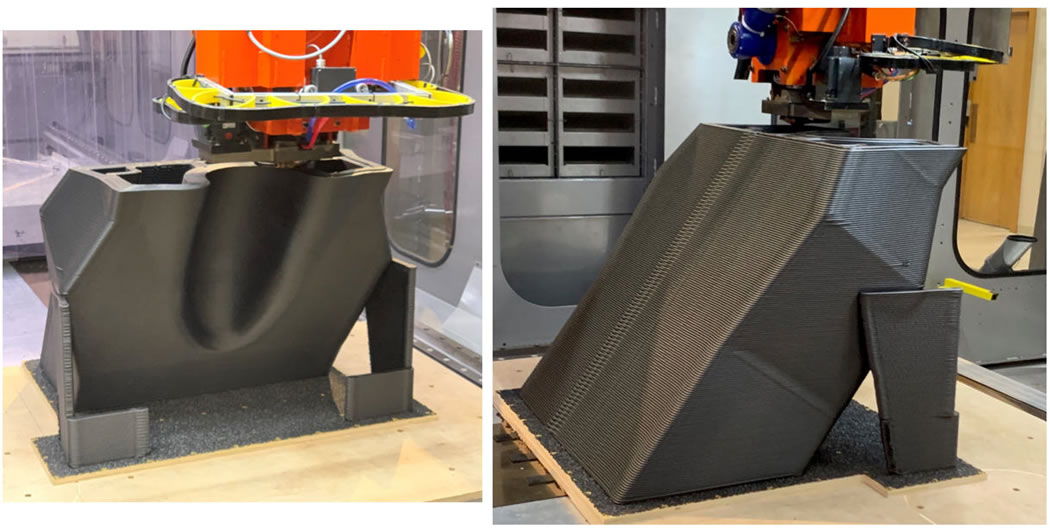

FRCE provided a high contour mold line surface to Boeing for generating the composite cure tool. The mold line shape was very aggressive and would stretch the large format additive manufacturing technology processes capability. The spherically shaped portion of the mold line offered the largest challenge, as the unsupported 3D printed angle limitation of approximately 45 degrees provides an interesting obstacle to overcome for the spherical mold line section of the tool. Boeing rotated the 3D print plane 35 degrees to avoid encroachment of the build angle limitation.

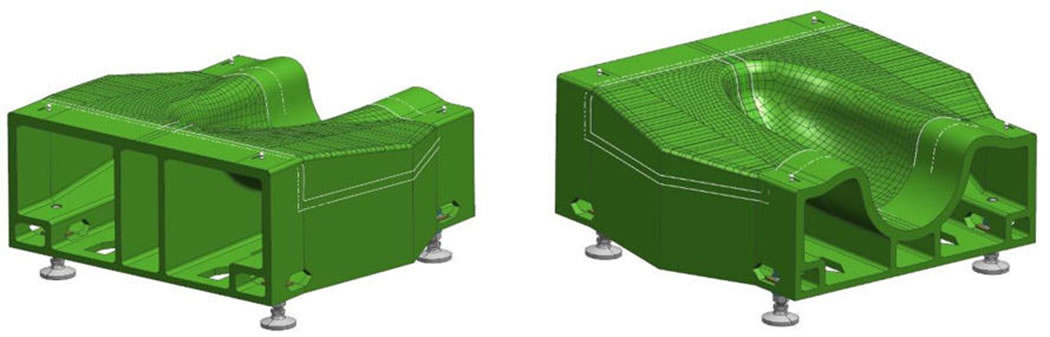

Final 3D Print Model

The new innovative build plane approach eliminated the requirement for temporary support material for the aggressive mold line shape. The new build angle would test the LSAM machine limits in an area never explored previously. TechmerPM PESU CF 1810 high temperature print material was used for the composite cure tool. High temperature materials present additional challenges during print over low temperature materials such as ABS CF. Two interim support features were added to compensate for the center of gravity shift of the print. The LSAM machine performed flawlessly during the composite cure tool print. The tool was printed in 7 hours and 26 minutes using 610 lbs of material.

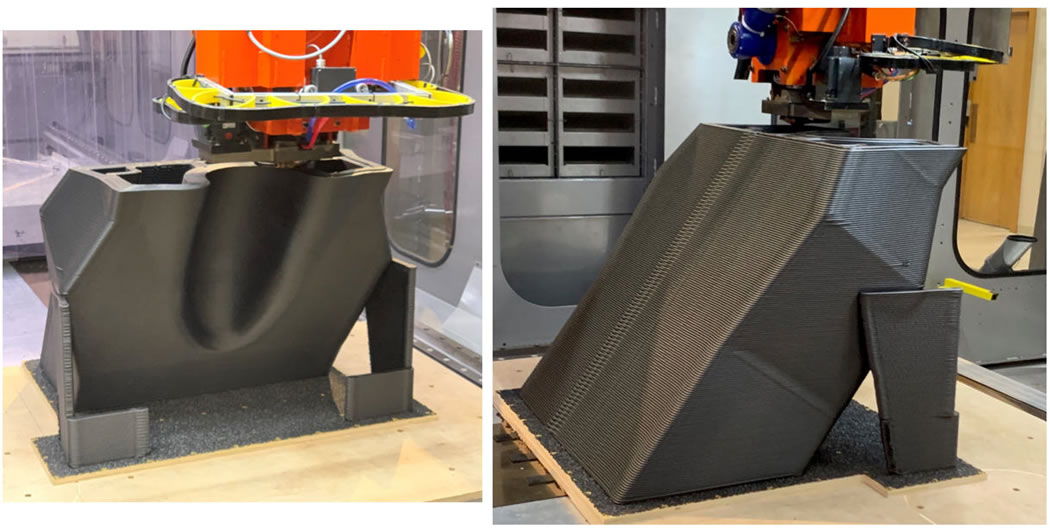

Composite Cure Tool printing on Thermwood LSAM

The composite cure tool was machined in 53 hours using the LSAM gantry router machine. The tool datum features, and removal of interim members, were machined prior to removal from the bead-board. The Thermwood LSAM machine offers the ability to machine and 3D print on a single platform. The composite cure tool mold line part surface achieved at surface profile tolerance of .020” (+/-.010”).

Machining the Composite Cure Tool on Thermwood LSAM

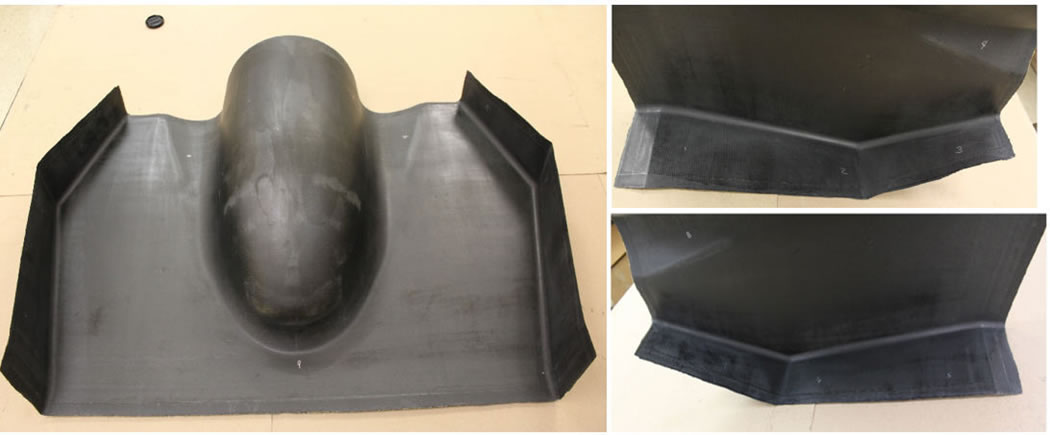

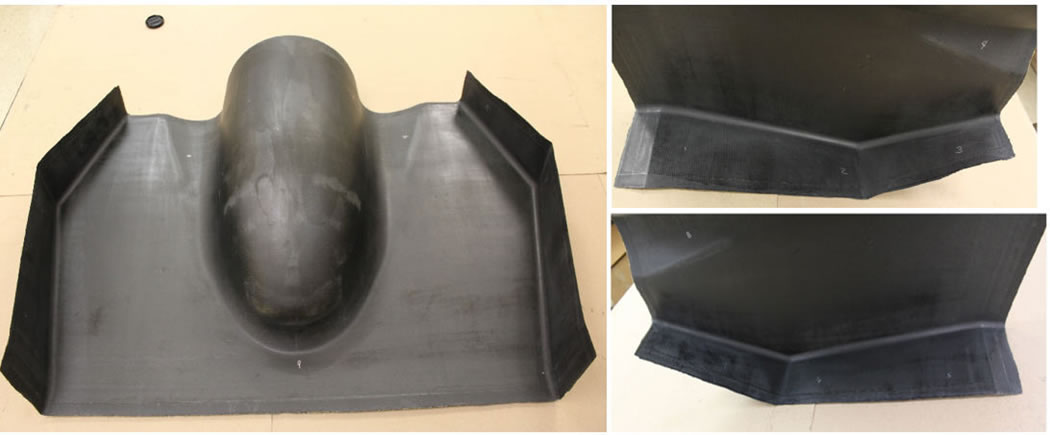

The Boeing Research and Technology (BR&T) laboratory performed functional testing on the LFAM composite cure tool to ensure vacuum integrity and dimensional stability requirements were reached. The LFAM tool performed as expected and achieved all requirements. Several composite parts were fabricated from the tool. The tool durability was assessed during the multiple autoclave cure cycles and fabricated (3) composite parts. The tool maintained dimensional stability and vacuum integrity throughout the functional testing and composite part manufacturing.

LFAM tool after Autoclave Cure

The composite cure tool was printed and NC machined on Thermwood’s Large Scale Additive Manufacturing (LSAM) 1020 machine. The LFAM technology cost savings was estimated at 50% compared to traditional tool fabrication methods, and reduced tool fabrication lead-time by 65%. The cost savings and tool fabrication cycle time reduction could provide enormous benefit to any organizations performing low volume or custom composite part fabrication and repair.

Composite part fabricated from LFAM tool

Nondestructive Inspection (NDI) was performed on the composite parts fabricated on LSAM tools. The NDI results did not indicate any porosity. Due to the complex shape of the composite demonstration part several NDI process were employed. X-ray and C-Scan results did not reveal any delaminations or defects.

The Bottom Line

The program benefited from a cooperative effort among several contributors to achieve success. The partnership between industrial technology leaders, Boeing and Thermwood coupled with the Office of Naval Research’s drive to transition technology, led to the successful program. “Collaborations such as this help expand the scope of capabilities of emerging large scale additive technology by addressing real world challenges that would be difficult for any single entity to define and address by itself. We look forward to new challenges moving forward”, says Thermwood CEO, Ken Susnjara.

Additional development is key to expand LFAM composite cure tooling implementation. Boeing Associate Technical Fellow Michael Matlack commented “The program provided significant results in validating additive manufacturing as a viable method of producing lower cost, capable tooling with substantial time savings over traditional methods.”

.jpg?width=400&name=cut_center_cnc_router_image%20(1).jpg)

Kylee Vaal is the daughter of Courtney and Scott Vaal of Jasper, IN. She is a graduate of Jasper High School.

Kylee Vaal is the daughter of Courtney and Scott Vaal of Jasper, IN. She is a graduate of Jasper High School.