Posted by Duane Marrett on Wed, Jun 10, 2020

Tags: Thermwood, Announcements, Scholarship, 2020

Thermwood is proud to announce that we will be awarding six scholarships to dependents of associates for the Class of 2020. Each recipient will receive a $2,000 renewable scholarship.

Since the introduction of these renewable scholarships, Thermwood has awarded over $200,000 to students wishing to further their education.

Cody Frakes is the son of Dawn Tullis of Santa Claus, IN and Jonathan Frakes. He is a graduate of Heritage Hills High School.

He has been a member of Beta Club, Rock/Paper/Scissors Club, Yearbook Staff and Fellowship of Christian Athletes (FCA). Cody was a member of the 2019 State Finalist Team and also received Academic All-State for Football.

He plans to study at Indiana University in the fall.

Hannah Schnuck is the daughter of Greg and Janie Schnuck of Santa Claus, IN. She is a graduate of Heritage Hills High School.

Hannah Schnuck is the daughter of Greg and Janie Schnuck of Santa Claus, IN. She is a graduate of Heritage Hills High School.

She has been involved in Beta Club, Student Council and Pep Club. Hannah participated in Feed My Starving Children and coached 7th grade volleyball. She was part of the Patriot Volleyball team and received Volleyball All-Conference PAC 2018/2019 and Volleyball All-State 1st Team 2019.

Hannah plans to attend Indiana University to study Business Management.

Jordan Yates is the daughter of Seth and Angie Yates of Lynnville, IN. She is a graduate of Tecumseh High School.

Jordan Yates is the daughter of Seth and Angie Yates of Lynnville, IN. She is a graduate of Tecumseh High School.

She has been involved in Drama Club, Art Club, Tribe and President of National Honor Society. Jordan was a member of the Varsity Swim and Golf team. She also was a member of the THS Dinner Theatre and the THS production of “The Little Mermaid”. She is the recipient of the Rising Star of Indiana award, Top Ten and ETFCU $5,000 Ted Hitch Scholarship for the 2020-2021 school year.

Jordan plans to attend University of Louisville for Biochemistry. Haley McDaniel is the daughter of Jason and Tammy McDaniel of Lynnville, IN. She is a graduate of Tecumseh High School.

Haley McDaniel is the daughter of Jason and Tammy McDaniel of Lynnville, IN. She is a graduate of Tecumseh High School.

She has been involved in the Drama Department, Art Club, Academic Team, Marching Band, Drum Major, Pep Band and Concert Band.

Haley plans to continue her education at Ivy Tech Community College.

Addison Fella is the daughter of Audrie and Michael Leisman of Tell City, IN. She is a graduate of Tell City High School.

Addison Fella is the daughter of Audrie and Michael Leisman of Tell City, IN. She is a graduate of Tell City High School.

She was president of the Pep Club, a member of the Spanish and Advocate Club. Addison participated on the high school Volleyball and Basketball teams. She was also involved on traveling Volleyball and Softball teams. She also received All Conference PAC for Volleyball.

Addison will continue her education and Volleyball career at IU South Bend this fall, and pursue a degree in Exercise Science.

Ian Treat is the son of Ryan and Alison Treat of Ferdinand, IN. He is a graduate of Forest Park High School.

Ian Treat is the son of Ryan and Alison Treat of Ferdinand, IN. He is a graduate of Forest Park High School.

Ryan was a member of SADD, Builders Club and Baseball Club K-8. He also participated in High School Baseball and Football.

Ian plans to attend Ivy Tech Community College to join the Heating, Ventilation, and Air Conditioning Program.

Thermwood would like to congratulate all seniors of the Class of 2020 and wish them the very best in their future studies and endeavors!

Posted by Duane Marrett on Fri, Jun 05, 2020

Tags: Thermwood, software update, Announcements, Cut Ready, Cut Center, Cut Center Updates, Shaker, Options

This update contains the following:

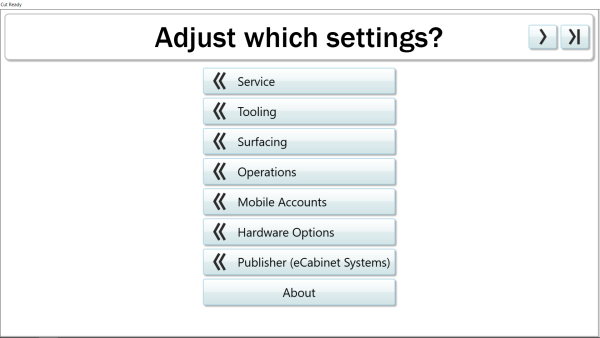

In this update, we have reorganized the Adjust Settings layout. For example, all mobile accounts have been grouped into one area and a new Hardware Options section has been added. We have also grouped Cutting and Air Assist options under the Operations button, while also adding a new user request option for Labeling.

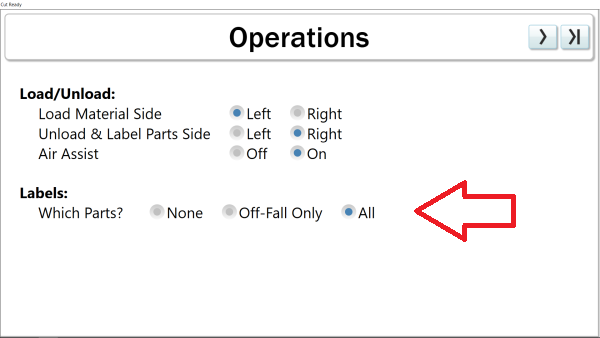

Now (within the Operations area), you will see some new labeling options that were requested by several users. These allow you to print labels for All Parts, Off-Fall Only or choose to not print any labels at all.

We have also addressed a few issues:

Posted by Duane Marrett on Thu, Jun 04, 2020

Tags: Thermwood, Model 43, CNC Router, Model 40, MTR 21, Rind Routing, Covid-19, ppe

Thermwood machine owner Rind Routing, (www.rindrouting.co.za) located in South Africa, was initially devastated to be forced to close down their business due to COVID-19. According to owner, Rayno von Schlicht, “Although the initial feeling was that this wouldn’t last very long, as a business owner, I was terribly concerned of the knock-on effect that a three week down-time would have on my business”

After the first week of the shut-down passed, Mr. von Schlicht noticed the 3D-printing “maker-community” designing face shield brackets and distributing them to first responders. He was intrigued by the idea and thought that Rind Routing could do something similar on a larger scale.

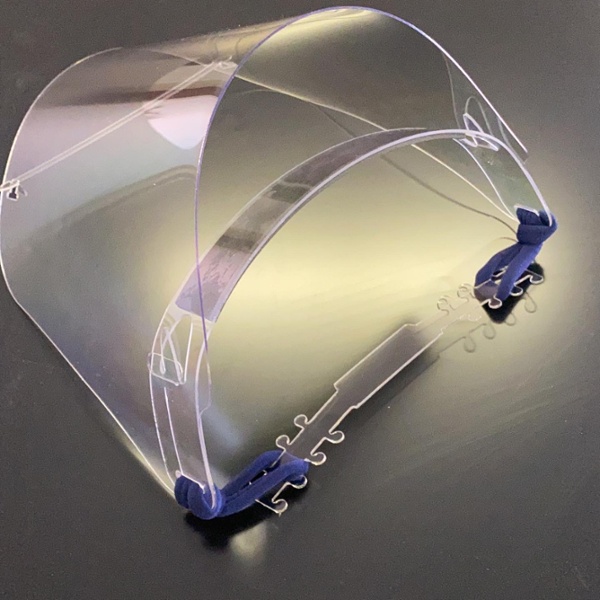

They located a dental distributor who loved their design, and after some small tweaks, developed a PPE product to manufacture on their three Thermwood CNC routers (Model 40, Model 43 and MTR 21) that was not just effective and comfortable for the end-user, but also allowed Rind Routing to return to work as an essential service!

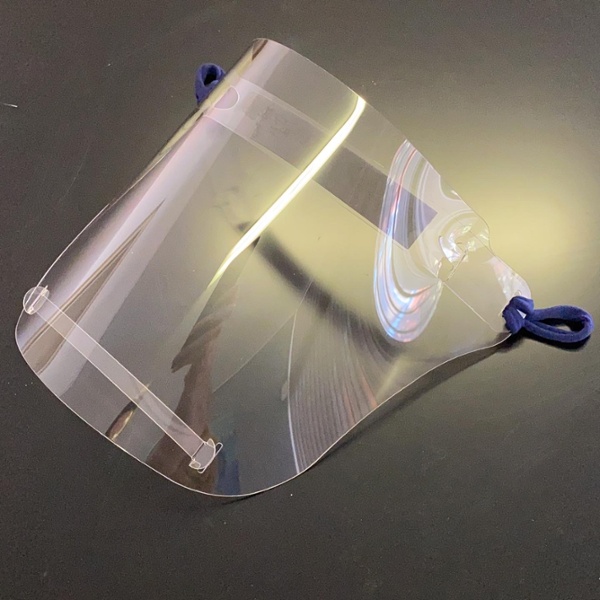

PPE face shield created by Rind Routing on their Thermwood CNC routers

According to von Schlicht “Since first starting this new venture, we have been able to churn out 5,000 face shields on our Thermwood Routers within three weeks and still have orders pouring in for more! This is proof to me that with a little vision & creativity, the willingness to try something new, and of course the correct tools to do so, you can achieve great things!”

PPE face shield created by Rind Routing on their Thermwood CNC routers

Thermwood MTR 21 at Rind Routing

Thermwood is a US based company with dealers and distributors worldwide. In addition to machine manufacturing and software development, Thermwood has a technical service organization that provides support, machine installation, training, retrofits, custom programming and production assistance. Please visit www.thermwood.com, call 1-800-533-6901 or email sales@thermwood.com for more information.

Posted by Duane Marrett on Fri, May 15, 2020

Tags: Thermwood, software update, Announcements, Cut Ready, Cut Center, Cut Center Updates, Shaker

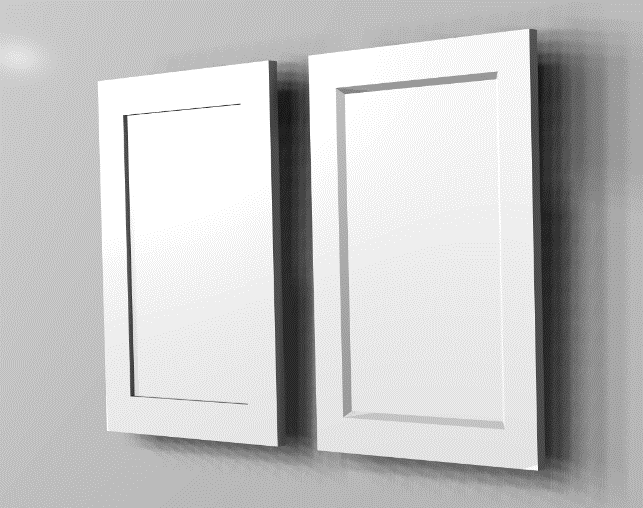

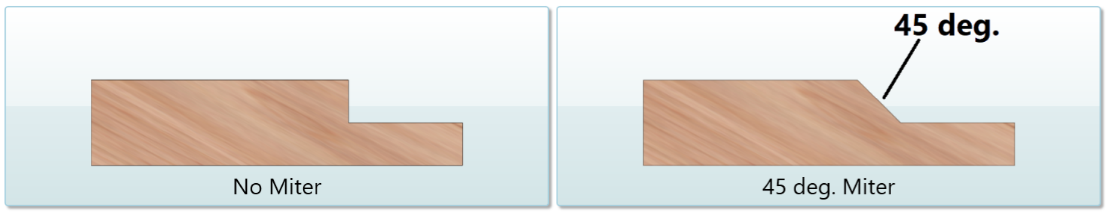

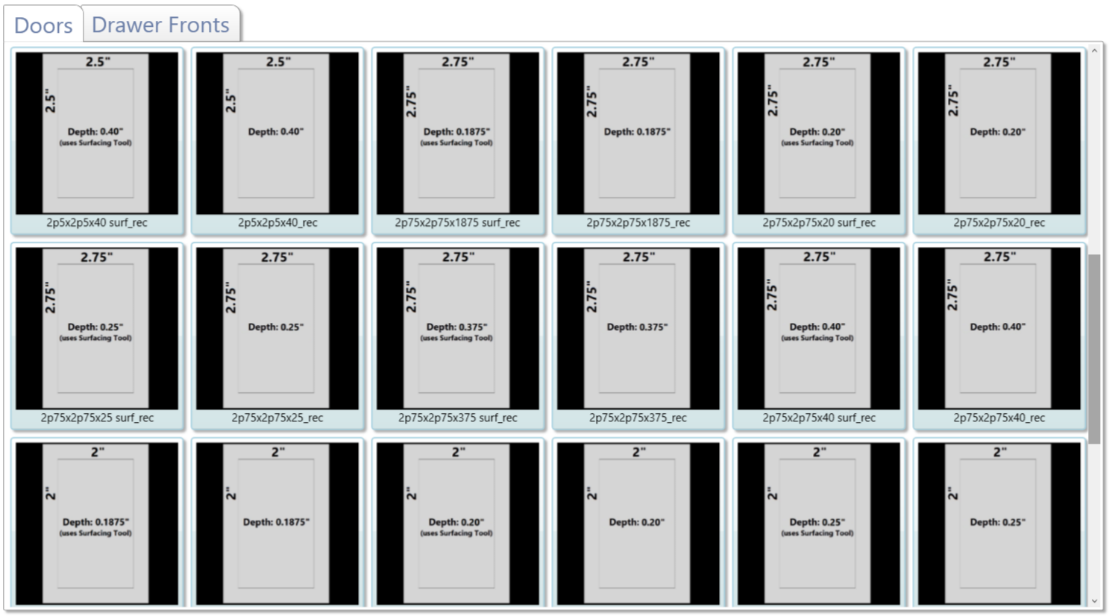

In this update, we’ve created a new category of MDF Doors dedicated entirely to the Shaker style, one of the most popular type of door styles within the industry. These are available with and without a miter cut on the inner profile. Miter cuts can be machined as a multi-pass or single pass door.

Shaker Doors are also available with different pocket depths (0.1875” to 0.4”) and different width for the Styles and Rails (2” to 3” in increments of 0.25”) giving you a wide range of options to choose from. The addition of Shaker Doors has added approximately 600 new door and drawer front definitions!

Posted by Duane Marrett on Thu, Apr 02, 2020

Tags: Thermwood, Announcements, Support, Bednark Studio, Covid-19, PETG, Face Shield

Thermwood machine owner, Bednark Studio (located in Brooklyn, New York), has engineered a disposable PETG Face Shield for health care professionals. They are sharing CNC router files and production information to any other manufacturers across the country who would like to supply these to hospitals, etc. that are in need.

Thermwood is here to assist anyone who would like to produce these face shields on their equipment (including non-Thermwood CNC routers). If you need help, or would like to do something similar, please contact us at 1-800-533-6901 or email at program@thermwood.com.

Please click here to download a .zip file with instructions, machine code files, tooling and material information.

Included in this download:

Material Required (supplies may be scarce):

Recommended Tooling:

Notes (from Bednark Studio):

More Information

Bednark Face Shield Story from the New York Times

Posted by Duane Marrett on Mon, Mar 30, 2020

Tags: Thermwood, Announcements, Support, Service, virtual service, Covid-19

During these unprecedented times, we wanted to reach out and thank all of our customers, and to let you know that Thermwood has been classified as an essential business for our involvement in critical manufacturing, logistics and the defense industrial base.

As such, we are operating as normally as possible to support our customers. We are available to support and assist via phone, email and virtual service.

For new machine purchases, our CNC Router and Additive Manufacturing experts can still evaluate your production needs and determine how you can best reduce costs and increase efficiency. We offer free live demonstrations of our equipment and software to qualified companies. These demonstrations can be done via Webex, Skype, as a time study, via dedicated hosted video and/or by completing your project and shipping it back to you for verification.

If you have any questions on how Thermwood can help improve your business, or if you need support, please give us a call at 1-800-533-6901 for sales (1-800-221-3865 for service) or click on the Request More Information link below.

We are all in this together and Thermwood is committed to doing our best to rise to this new challenge and support all of our customers both existing and new.

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood has also become the technology and market leader in large scale additive manufacturing systems for thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) machines that both 3D print and trim on the same machine. These are some of the largest and most capable additive manufacturing systems ever produced and are marketed to major companies in the aerospace, marine, automotive and foundry industries as well as military, government and defense contractors.

Posted by Duane Marrett on Tue, Mar 17, 2020

Tags: Thermwood, Announcements, Video, 3D printing, Additive, LSAM, Pattern, Foundry, LSAM 1020

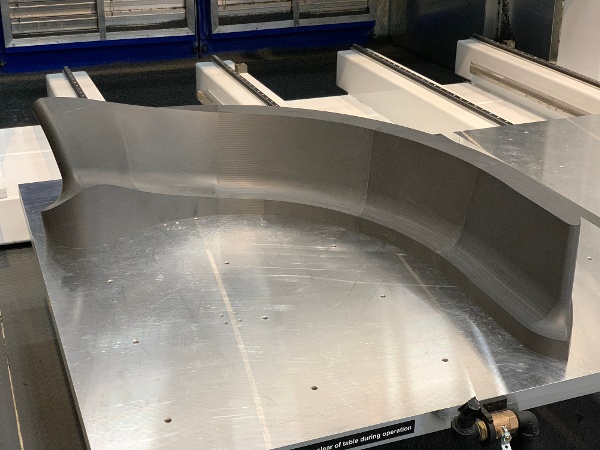

Thermwood recently completed a 3D printed multi-piece foundry pattern. The pattern was printed on an LSAM 1020, and machined on a Thermwood 5 Axis Model 90 (because of other projects that were pending on the LSAM).

The pattern was printed out of ABS (20% carbon fiber fill). Print time for the project was 6 hours and 40 minutes, and the trim time was a little over 47 hours with multiple fixture setups.

Click below to watch a video of the process:

The final pattern after trimming

The completed and assembled pattern.

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood has also become the technology and market leader in large scale additive manufacturing systems for thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) machines that both 3D print and trim on the same machine. These are some of the largest and most capable additive manufacturing systems ever produced and are marketed to major companies in the aerospace, marine, automotive and foundry industries as well as military, government and defense contractors.

Posted by Duane Marrett on Thu, Mar 12, 2020

Tags: Thermwood, Announcements, Trade Shows, 3D printing, Additive, LSAM, AeroDef

Aerodef 2020 (March 17th and 18th) in Fort Worth, TX, starts next week, and Thermwood will be there (Booth #615) to talk LSAM (Large Scale Additive Manufacturing).

Aerodef 2020 (March 17th and 18th) in Fort Worth, TX, starts next week, and Thermwood will be there (Booth #615) to talk LSAM (Large Scale Additive Manufacturing).

We will have the the 18 1/2 foot long Bell Helicopter Blade Mold on hand in addition to other 3D printed samples to see and touch as well as videos and literature. Our knowledgeable sales staff will also be on hand to help answer any questions you may have about the future of Large Scale Additive Manufacturing and how the Thermwood LSAM can help your company charge ahead in this new area.

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood has also become the technology and market leader in large scale additive manufacturing systems for thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) machines that both 3D print and trim on the same machine. These are some of the largest and most capable additive manufacturing systems ever produced and are marketed to major companies in the aerospace, marine, automotive and foundry industries as well as military, government and defense contractors.

Posted by Duane Marrett on Thu, Mar 05, 2020

Tags: Thermwood, Announcements, 3D printing, Additive, LSAM, LSAM 1010

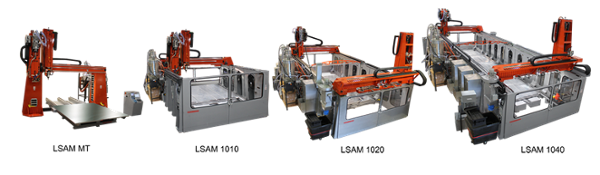

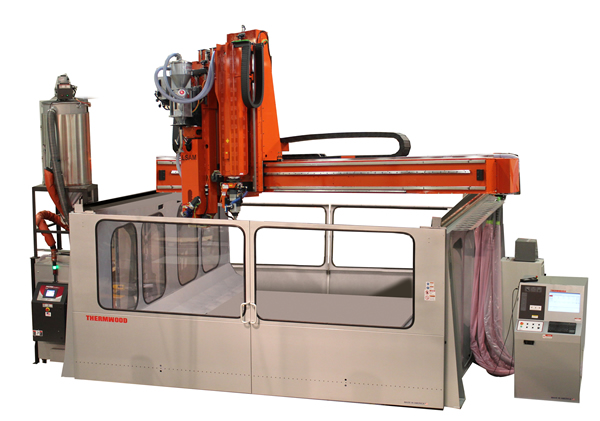

Thermwood recently announced the LSAM MT, a lower cost moving table version of its industry-leading LSAM (large scale additive system). Although Thermwood has hundreds of open moving table CNC routers in operation, similar in configuration to the MT, and believes this configuration will also work for many LSAM customers, several larger customers requested an enclosed machine configuration that is the same size as the MT, but configured like the larger LSAM high wall systems.

To address this request for a lower cost enclosed machine, Thermwood has announced the LSAM 1010. This system uses the walls from the larger LSAM systems with the gantry, control and sub-systems from the MT.

The new LSAM 1010 has both the print and trim heads on same the gantry just like the LSAM MT.

A single moving gantry on the LSAM 1010 carries both the print and trim heads just like on the MT.

The LSAM 1010 features a fixed 10 foot by 10 foot table. A single moving gantry carries both the print and trim heads as on the MT and, like the MT, it can both print and trim (but not at the same time). The print and trim heads on all Thermwood LSAMs are the same, so all machines can process virtually any reinforced composite thermoplastic materials available today.

The print and trim heads on all Thermwood LSAMs are the same, so all machines can process virtually any reinforced composite thermoplastic materials available today.

Although the LSAM 1010 is slightly higher in price than the MT, it is noticeably less than the larger LSAMs and generally less than the cost and complexity of trying to add an external enclosure to the MT.

In addition, even though the LSAM 1010 is slightly wider than the larger LSAMs (to accommodate mounting both the print and trim heads on the same gantry), the overall footprint of the 1010 is actually slightly smaller than required for the MT. And, like the MT, the 1010 can be purchased as a print only machine.

Thermwood believes that, since it is enclosed like the larger LSAMs, the LSAM 1010 can be built to meet European CE requirements, just like the larger machines.

With the introduction of the LSAM 1010, it is clear that Thermwood is committed to responding to customer requests and providing its industry-leading LSAM additive manufacturing technology in a variety of configurations to better fit varying customer requirements.

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood has also become the technology and market leader in large scale additive manufacturing systems for thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) machines that both 3D print and trim on the same machine. These are some of the largest and most capable additive manufacturing systems ever produced and are marketed to major companies in the aerospace, marine, automotive and foundry industries as well as military, government and defense contractors.

© Thermwood Corporation. All Rights Reserved