Thermwood's AutoProcessor 43 Machining Center is an all-new complete, nested-based, CNC routing system for machining cabinet boxes, custom furniture and basically any nested type of sheet product.

AutoProcessor 43

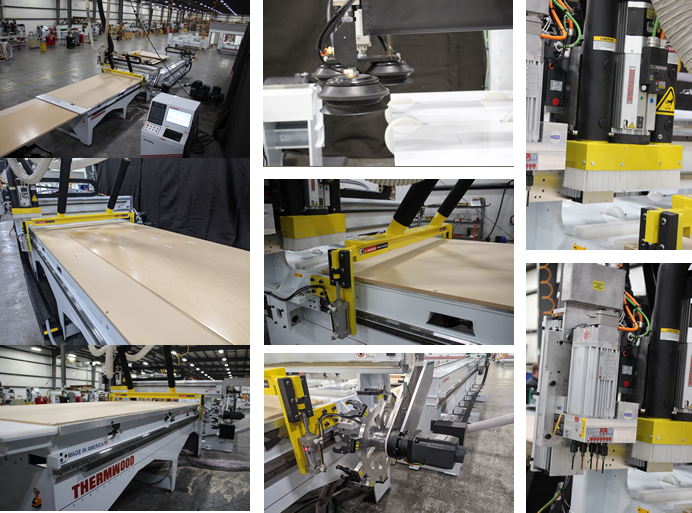

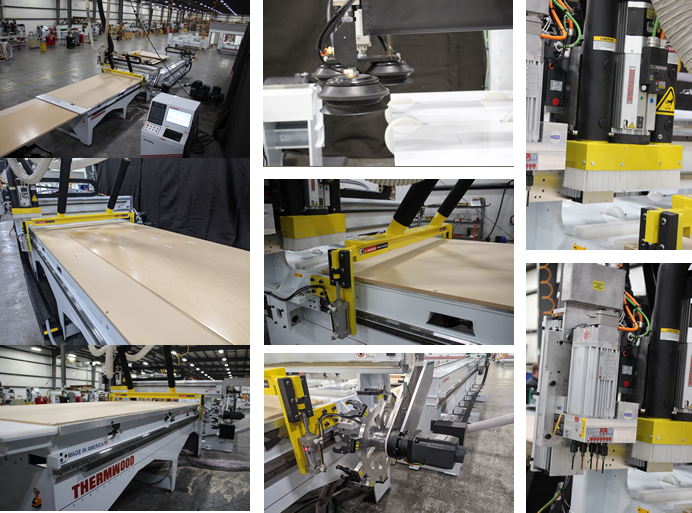

The AutoProcessor 43 is fully automatic from labeling and positioning of the sheets, to machining and off-loading the machined parts.

With each cycle, the machine simultaneously and automatically:

- Labels each part area on the sheet

- Moves and automatically positions the sheet on the table

- Machines the material while labeling the next sheet

- Simultaneously off-loads the finished parts and reloads the next sheet

- Continuously repeats the process

Standard Features

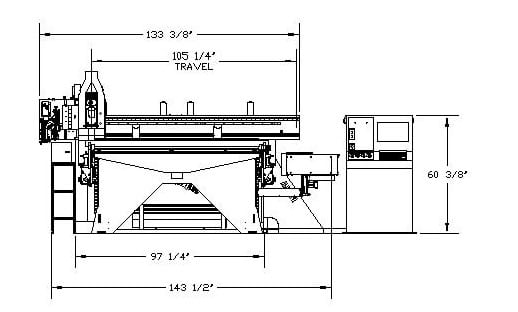

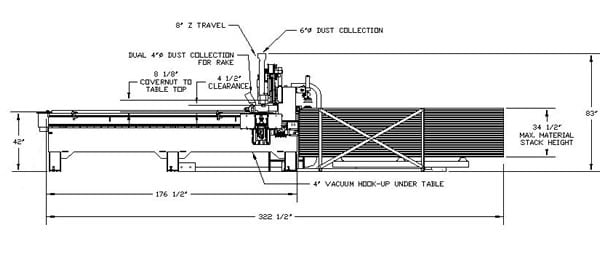

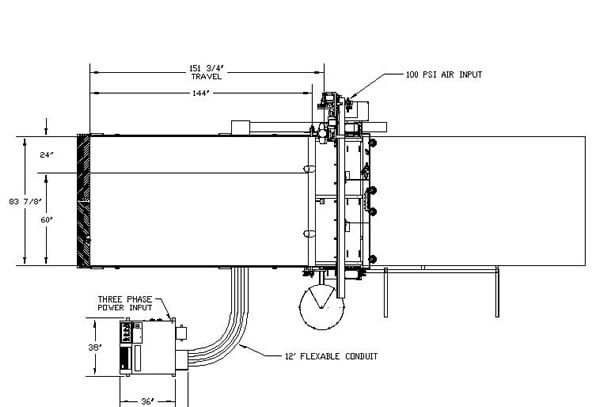

- 5'x10' (1.5m x 3.0m) Fixed Table

- Moving Gantry

- 10 Position Automatic Rotary Tool Change System

- 12 HP (9kw) ISO Electro Spindle

- High-Flow Vacuum Table

- Automatic 6000 LB Lift Table for Loading

- Simultaneous Automatic Labeling System

- Automatic Dust Extraction During the Unload Raking Process

- Automatic Pop Up Pins

- Automatic Tool Length Sensor

- Automatic Lubrication System

- Automatic Sheet Load/Unload System

- Automatic Sheet Positioning System

- Siemens Intelligent Servo Drives Throughout

- 3D Laser Compensated Axis Alignment

- SuperControl

- Control Nesting

- 5 Spindle Drill Bank (Optional)

- Unload Sorting Table (Optional)

- Touch Screen Control (Optional)

- Made in America

Well Equipped with Features/Options

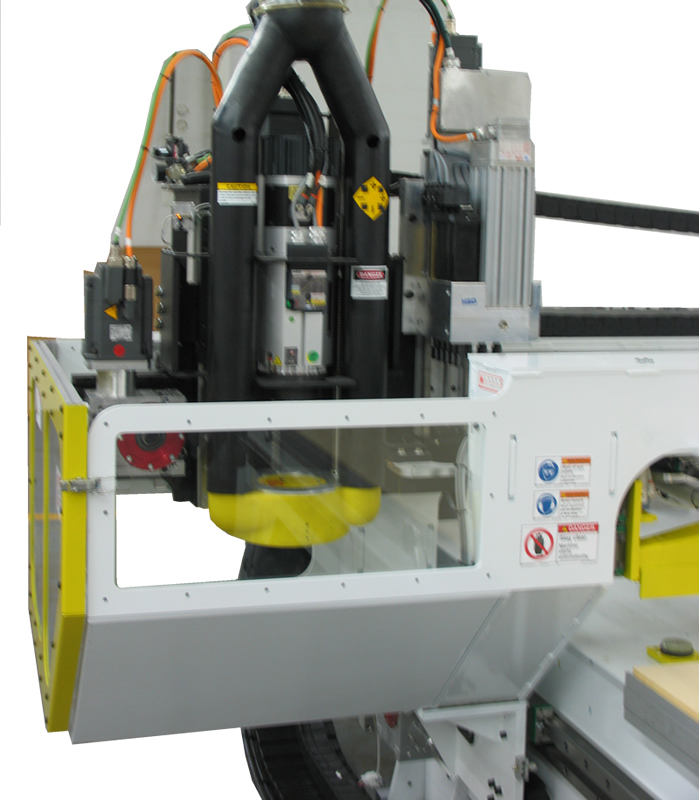

12 HP (9KW) SPINDLE

A direct driven spindle with a speed range up to 24,000 RPM. the High Frequency Spindle is cooled with an electric fan for quieter running and contains ceramic bearings for longer life and for less maintenance. The 12 HP (9kw) spindle provides the user with a heavy duty, precision spindle for high performance and reliability. Standard

ROTARY AUTOMATIC TOOL CHANGER

10 Position Rotary Automatic Tool Changer Includes (10) ISO-30 Tool Holders and collets. Max tool size is 2" (50mm) in diameter and 3.25" (83mm) in length. Standard (optional HSK63F)

AUTOMATIC CNC LABELER SYSTEM

The Automatic CNC Labeler System labels the sheet before the machining operation. The labels assist with sorting and assembling finished parts. Optional

AUTOMATIC LOAD/UNLOAD SYSTEM

Automatically loads sheets up to 60" x 120" (1.5m x 3.0m) to assist operator with unloading the machine and automatically position the sheet. Each individual sheet is elevated and positioned by a series of programmable vacuum cups. A steel rake is mounted in front of the router motor and travels with the machine gantry allowing parts to be removed off the front of the table. Dust extraction/table sweep occurs during the rake process. Standard

FIVE SPINDLE DRILL BANK

The drill unit is a vertical boring head with five vertical spindles. The spindles are on 32mm centers. The drill unit can be independent. Optional

VACUUM PUMP

Universal Vacuum System is a unique method for holding panels to the table top for machining. A sheet of MDF is used as a work surface on the top of the table. The high flow pump vacuums through the work surface, holding the part to the table. Pumps are available in different sizes. Optional

About Thermwood Corporation

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood is a US based, multinational, diversified CNC machinery manufacturer that markets its products and services through offices in 11 countries. Thermwood is the oldest manufacturer of highly flexible 3 & 5 axis high-speed machining centers known as CNC routers.

Thermwood has also become the technology and market leader in large scale additive manufacturing systems for thermoplastic composite molds, tooling, patterns and parts with its line of LSAM (Large Scale Additive Manufacturing) machines that both 3D print and trim on the same machine. These are some of the largest and most capable additive manufacturing systems ever produced and are marketed to major companies in the aerospace, marine, automotive and foundry industries as well as military, government and defense contractors.

Please come and visit us at CNC Automation booth #2013.

Please come and visit us at CNC Automation booth #2013.

The AutoProcessor 5'x10' is a high-speed, automatic load/unload, heavy-duty CNC routing system for nested based feed through machining. It is used in nested based production of cabinets, closets and custom furniture.

The AutoProcessor 5'x10' is a high-speed, automatic load/unload, heavy-duty CNC routing system for nested based feed through machining. It is used in nested based production of cabinets, closets and custom furniture.  Features:

Features: