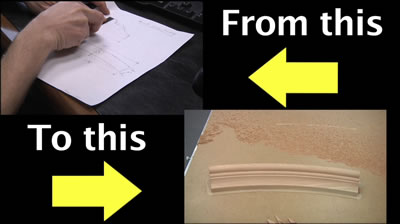

Thermwood's Profile Modeler allows you to quickly create a molding or custom shape from a sketch or drawing on a Thermwood CNC Router with no special shaped tooling required.

Thermwood's Profile Modeler allows you to quickly create a molding or custom shape from a sketch or drawing on a Thermwood CNC Router with no special shaped tooling required.

This video demonstrates using Profile Modeler to create a custom curved cherry molding from Sketch - to Profile Modeler - to Machine - to Completed Shape.

Steps used in the video:

In eCabinet Systems:- Verify the measurements

- Create the shape using Shape Manager in eCabinet Systems

- Create Tool

- Apply Tool to create Shape

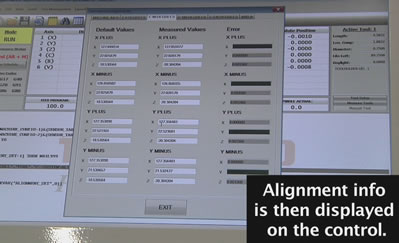

On Thermwood QCore SuperControl:

- File loaded into Profile Modeler on QCore SuperControl

- Verify Tool Path

- Run Program

- Machining Part (Roughing/Finishing/Detail Passes)

- No special shaped tooling required - Tools Used: 1/2 Straight, 1/2 Ballnose, 1/8 Ballnose, 1/8 Flat

- Completed Shape