See us Live

Posted by Duane Marrett on Tue, Apr 25, 2023

Tags: Thermwood, Video, Thermwood LSAM, VLP, LSAM AP, Fixture

Posted by Duane Marrett on Fri, Apr 14, 2023

Tags: Thermwood, Video, virtual tour, Thermwood LSAM, LSAM MT, LSAM 1020

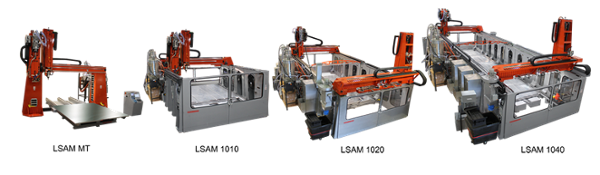

Thermwood has been the market and technology leader in Large Format Additive Manufacturing (LFAM) since 2016, thanks to our innovative LSAM (Large Scale Additive Manufacturing) systems.

We offer the broadest range of LFAM (Large Format Additive Manufacturing) systems in the industry, to help you find the perfect solution for your needs and budget. But LSAM systems are more than just 3D printers - they're real production systems, capable of producing industrial fixtures, molds (including high temp), tooling, foundry patterns, prototypes and end products from a wide variety of both low and high temp materials.

𝗔 𝗳𝗲𝘄 𝗟𝗦𝗔𝗠 𝗮𝗱𝘃𝗮𝗻𝘁𝗮𝗴𝗲𝘀:

• LSAM systems offer three printing orientations - HLP (Horizontal Layer Printing), VLP (Vertical Layer Printing), allowing parts to be printed that are as long as the machine table and ALP (Angle Layer Printing), the ability to print at a 45 degree angle.

• With the fastest print heads in the industry, our LSAM systems can print at speeds from up to 200lbs per hours to over 500 lbs per hour.

• Choose from Print-only or Print-and-Trim combinations with table sizes ranging from 5’x5’ to 15’x40’ and beyond.

• Save both time and money over traditional methods - case study here: https://bit.ly/3zWoWjk

𝗦𝗲𝗲 𝘂𝘀 𝗹𝗶𝘃𝗲:

We will be at a variety of upcoming shows in the next few weeks, and you can visit to learn more about LSAM.

Check us out next week at SAMPE 2023 in Seattle (booth E10), JECWorld 2023 in Paris starting on April 25th (US Pavilion, Hall 6, booth Q49) and printing live with #SABIC’s LNP™ ELCRIN™ WF006NiQ resin on an LSAM AP 510 at Rapid 2023 in Chicago starting May 2nd (booth #2418).

Don't settle for less when it comes to your production process. Upgrade to Thermwood's LSAM system and take your manufacturing to the next level!

Visit https://bit.ly/3GFE3RR to learn more about LSAM.

LSAM Examples

Posted by Duane Marrett on Fri, Mar 17, 2023

Tags: Thermwood, Video, virtual tour, Thermwood LSAM, Boeing, LSAM 1020, Boeing Auburn, Discovery Education

Posted by Duane Marrett on Wed, Nov 09, 2022

Tags: Thermwood, CNC, 5 Axis, CNC Router, Model 90, Video, Copper

![]()

More Info on the Model 90: https://bit.ly/m90thm

Posted by Duane Marrett on Fri, Nov 04, 2022

Tags: Thermwood, Announcements, Trade Shows, Video, IMTS, Large Scale, Thermwood LSAM, LSAM Additive Printers

More info on LSAM: https://bit.ly/LSAM_INFO

Posted by Duane Marrett on Mon, Aug 08, 2022

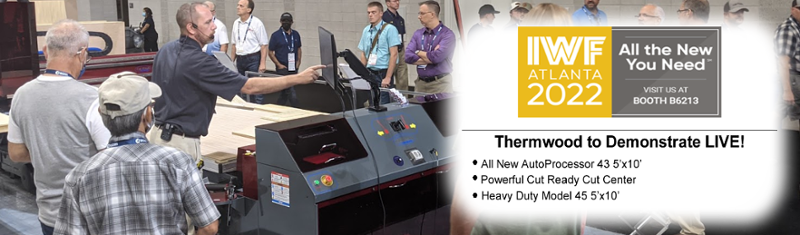

Tags: Thermwood, Trade Shows, Model 45, Cut Ready, Cut Center, Video, IWF, Discount, AutoProcessor 43, 2022

Please Click Here to Register for IWF with 60% off Advanced Registration courtesy of Thermwood, and plan to stop by our booth #B6213 to see our superior technology in action!

For IWF 2022, Thermwood Corporation, an innovator in the design and manufacture of American Made 3 and 5 Axis CNC Routers, is proud to demonstrate three systems. We’ll have our all new AutoProcessor 43 510, our powerful Cut Ready Cut Center and our heavy-duty Model 45 510 machining on site.

The AutoProcessor 43 5'x10' is an all-new complete, nested-based, CNC routing system for machining cabinet boxes, custom furniture and basically any nested type of sheet product.

It is fully automatic from labeling and positioning of the sheets, to machining and off-loading the machined parts.

With each cycle, the machine simultaneously and automatically:

Thermwood will also be demonstrating the award-winning Cut Ready Cut Center. This powerful system helps you quickly and easily create most products a cabinet shop would want to make without a CNC programmer (cabinets, furniture, doors, drawers, moldings, stair stringers and much more). Just tell it what you want to make via a simple touch-screen interface, and it makes it. Or, you can operate it as a traditional CNC router.

Most people can operate it with little or no training or guidance. It is complete, fully contained with all the ancillary equipment smoothly integrated into a package that almost runs itself.

If you build custom cabinets, and want to automate your machining...you really only have two choices. You can do it the easy way…or the hard way.

If you build custom cabinets, and want to automate your machining...you really only have two choices. You can do it the easy way…or the hard way.Designed and engineered in America, the Cut Ready Cut Center is made to simplify and automate your production.

It allows you to remain a cabinet shop, focused on making custom cabinets, instead of a software company, worried about learning difficult and expensive software.

The Cut Center takes care of both the big and small details so you don't have to!

Making product on the Cut Center requires neither a CNC programmer nor a trained machine operator. Pretty much anyone can run a Cut Center, and make anything a cabinet shop might need (cabinets, closets, doors, moldings, stair stringers, furniture...and much more)!

We will also be machining solid wood and aluminum and plywood sheet stock on the Model 45.

The heavy-duty Model 45 is designed for a variety of functions, including the machining of rotary operations when equipped with our optional C-Axis. This expands the capability of this already useful machine to include volutes, carvings, chair parts, stair components and much more.

Posted by Duane Marrett on Wed, Jul 20, 2022

Tags: Thermwood, Trade Shows, Model 45, Cut Ready, Cut Center, Video, IWF, AutoProcessor 43, 2022

For IWF 2022, Thermwood Corporation, an innovator in the design and manufacture of American Made 3 and 5 Axis CNC Routers, is proud to demonstrate three systems. We’ll have our all new AutoProcessor 43 510, our powerful Cut Ready Cut Center and our heavy-duty Model 45 510 machining on site.

The AutoProcessor 43 5'x10' is an all-new complete, nested-based, CNC routing system for machining cabinet boxes, custom furniture and basically any nested type of sheet product.

It is fully automatic from labeling and positioning of the sheets, to machining and off-loading the machined parts.

With each cycle, the machine simultaneously and automatically:

Thermwood will also be demonstrating the award-winning Cut Ready Cut Center. This powerful system helps you quickly and easily create most products a cabinet shop would want to make without a CNC programmer (cabinets, furniture, doors, drawers, moldings, stair stringers and much more). Just tell it what you want to make via a simple touch-screen interface, and it makes it. Or, you can operate it as a traditional CNC router.

Most people can operate it with little or no training or guidance. It is complete, fully contained with all the ancillary equipment smoothly integrated into a package that almost runs itself.

Jody Wilmes (Cut Ready Product Manager) helps you understand the differences between the Cut Center and a regular CNC Router.

Jody provides an in-depth look at what it takes to successfully operate each machine, and lists some of the additional expenses and things to consider when shopping for an automated solution.

We will also be machining solid wood and aluminum and plywood sheet stock on the Model 45.

The heavy-duty Model 45 is designed for a variety of functions, including the machining of rotary operations when equipped with our optional C-Axis. This expands the capability of this already useful machine to include volutes, carvings, chair parts, stair components and much more.

Posted by Duane Marrett on Wed, Dec 09, 2020

Tags: Thermwood, Announcements, Video, 3D printing, LSAM, Thermwood LSAM, LSAM MT, LSAM 1010, LSAM 1020, 2020, Review

Thermwood LSAM 2020 - Year in Review

Thermwood LSAM 2020 - Year in ReviewThe last 12 months have seen an incredible level of disruption in all industries, fueled in large part by the coronavirus pandemic. COVID-19 has impacted nearly every aspect of the global economy, from manufacturing to supply chains to travel.

The additive industry wasn’t spared, with event cancellations and disruptions to regular business becoming the norm. Thermwood pivoted in 2020 to continue our focus on innovation and development with our LSAM (Large Scale Additive Systems) line, and have made many new discoveries and advancements in our additive manufacturing program.

Below, we highlight some of the notable LSAM moments from 2020 that leaves us hopeful for the future of large scale additive manufacturing in 2021 and beyond:

To address the need for a lower cost enclosed additive machine, Thermwood developed the LSAM 1010. This system uses the walls from the larger LSAM systems with the gantry, control and sub-systems from the LSAM MT.

The LSAM 1010 features a fixed 10 foot by 10 foot table. A single moving gantry carries both the print and trim heads as on the MT and, like the MT, it can both print and trim (but not at the same time). The print and trim heads on all Thermwood LSAMs are the same, so all machines can process virtually any reinforced composite thermoplastic materials available today.

With the introduction of the LSAM 1010, it became clear that Thermwood is committed to responding to customer requests and providing its industry-leading LSAM additive manufacturing technology in a variety of configurations to better fit varying customer requirements.

This was a great exercise to demonstrate the capabilities of an LSAM to quickly make a multi-piece foundry pattern out of ABS (20% carbon fiber fill).

The pattern was printed on an LSAM 1020 in 6 hours and 40 minutes, and machined on a Thermwood 5 Axis Model 90 (because of other projects that were pending on the LSAM).

Thermwood designed, fabricated and put into operation the largest machine it has ever built. The metalworking machine, dubbed internally as the M400, weighs 51 Tons (103,000 pounds) and is mounted on a special isolated, double steel reinforced concrete pad. It has a 15 foot wide, 35 foot long floor level steel table that by itself weighs 21,000 pounds.

In August, Thermwood demonstrated it's VLP (Vertical Layer Printing) capabilities on an LSAM MT 1010. The high-temperature part was printed out of Techmer PM blended 25% carbon fiber filled PSU/PESU.

Total print time for the project was 16 hours and 40 minutes, and the final weight of the part was 1,190 lbs. The final part dimensions were 108.6" (x) x 33" (Y) x 45" (Z).

In September, Thermwood partnered with General Atomics to produce a CNC trim tool. The tool was printed from ABS (20% Carbon Fiber Filled) in 16 hours. Total machining time was 32 hours. The final part weighed 1,190 lbs, and represented a cost savings of around $50,000 when compared to traditional methods.

Total lead time for the part decreased from 6-8 weeks to less than 2 weeks by utilizing the powerful LSAM system.

Also in September, LSAM Product Manager, Scott Vaal, took us on an informative tour of the Thermwood LSAM.

In this tour, Scott explains all the different aspects of the Thermwood LSAM and provides insight into this unique solution for large scale additive manufacturing.

In October, Thermwood printed a several sections from a 51 foot long yacht hull mold to demonstrate how only a single mold may be needed for the manufacture of larger vessels, such as yachts.

The printed sections of this test mold were made of carbon fiber reinforced ABS from Techmer PM. ABS was chosen because of its physical properties and relatively low cost compared to other reinforced thermoplastics

Posted by Duane Marrett on Mon, Nov 23, 2020

Tags: Thermwood, Announcements, Model 45, Video, Demonstrations, Machining

Watch a Thermwood Model 45 5'x10' Machine an Aluminum Sign

The Model 45 is a heavy-duty and versatile three axis CNC designed for composites, plastics, aluminum, cabinets, wood and nested base panels. Available in either single or dual spindles with optional rotary axis. Available Table Sizes: 5'x'5, 5'x10', 5'x12', 6'x12' and 7'x12'

Model 45 5'x10' CNC Router - Learn More

Posted by Duane Marrett on Thu, Nov 12, 2020

Tags: Thermwood, Announcements, Model 45, Video, Demonstrations, Machining

Watch a Thermwood Model 45 5'x10' Machine a Bar Stool Leg using an Optional Rotary Playback Device and aggregate tooling.

The Model 45 is a heavy-duty and versatile three axis CNC designed for composites, plastics, aluminum, cabinets, wood and nested base panels. Available in either single or dual spindles with optional rotary axis. Available Table Sizes: 5'x'5, 5'x10', 5'x12', 6'x12' and 7'x12'

Model 45 5'x10' CNC Router - Learn More

© Thermwood Corporation. All Rights Reserved