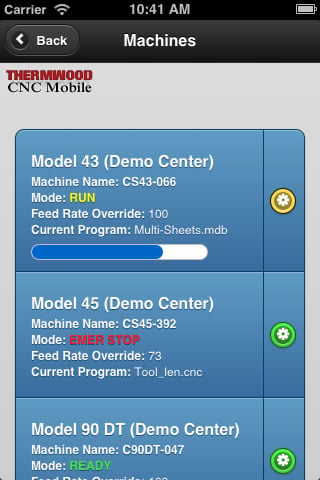

The Thermwood CNC Mobile App allows users to monitor their Thermwood CNC router(s) and the programs that run on them from anywhere. This app permits the user to obtain the following information on a tablet or smartphone (updated every 30 seconds):

The Thermwood CNC Mobile App allows users to monitor their Thermwood CNC router(s) and the programs that run on them from anywhere. This app permits the user to obtain the following information on a tablet or smartphone (updated every 30 seconds):

-

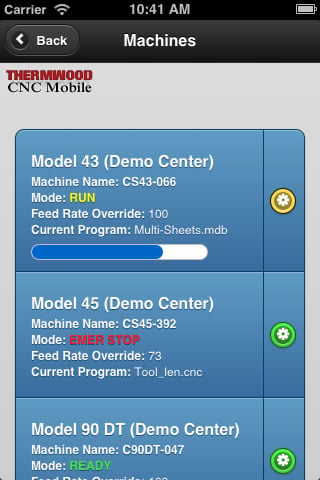

A listing of every machine you own (includes an optional user customizable nickname)

-

The current state (ready, running or in e-stop)

-

The current Feed Override setting

-

The current program loaded and or running

-

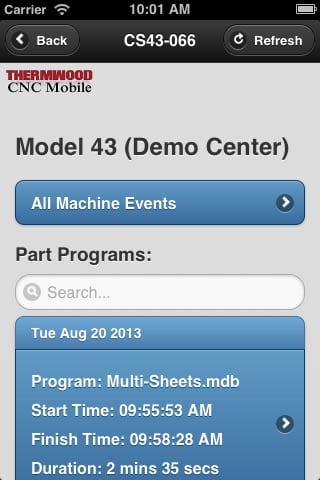

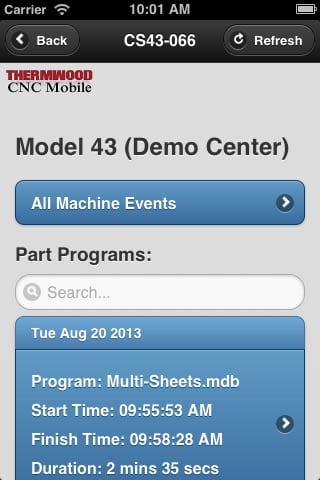

A listing of all current and past part programs loaded/ran in chronological order with extensions

-

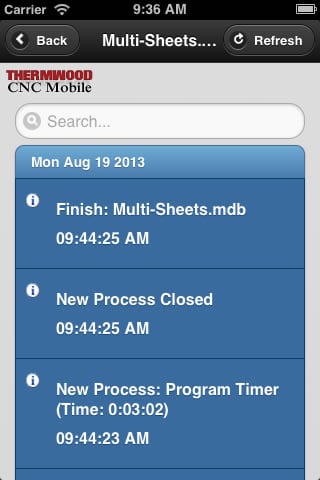

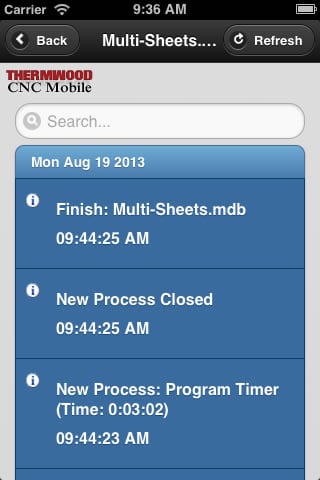

A listing of machine events during each part program in chronological order

-

A listing of the cycle time of every part program ran in chronological order

-

A listing of completion or interrupt times in each part program ran in chronological order

-

All machine events in chronological order with filtering

-

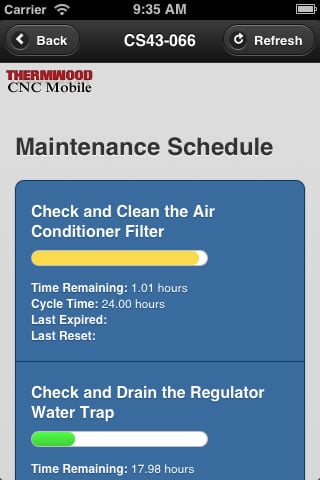

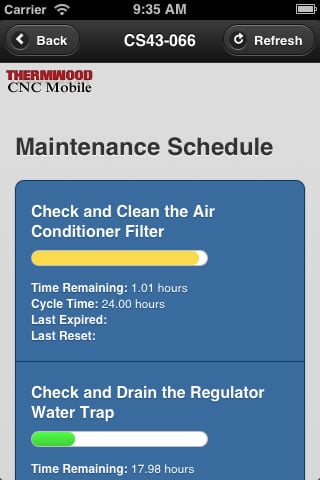

Monitor scheduled maintenance with a cycle time countdown as well as a graphical countdown progress bar

-

A time stamp listing of all previous maintenance performed

-

The ability to request a service phone call from a Thermwood Support Technician right from your device.

Domestic Eligibility: While this app is free to install, only machines enrolled in Thermwood’s Advanced Support program or subscribed to Virtual Service will deliver the monitoring service. The machine also requires QCore control software version 8.5.5 or newer. All new machines will include the ability to use this app during the warranty period of the machine free of charge.

International Eligibility:

All new international machine customers will be able to use the Thermwood CNC Mobile App free of charge during the machine warranty. Any non-US customers wishing to continue using this mobile app after the warranty will be allowed to do so for a $50 a month fee automatically billed each month to a credit card. The customer will be notified when the warranty of the machine is about to expire and asked at that time if he/she would like to continue this service.

Also available on any browser here: https://server.thermwood.com/thmmobileapp

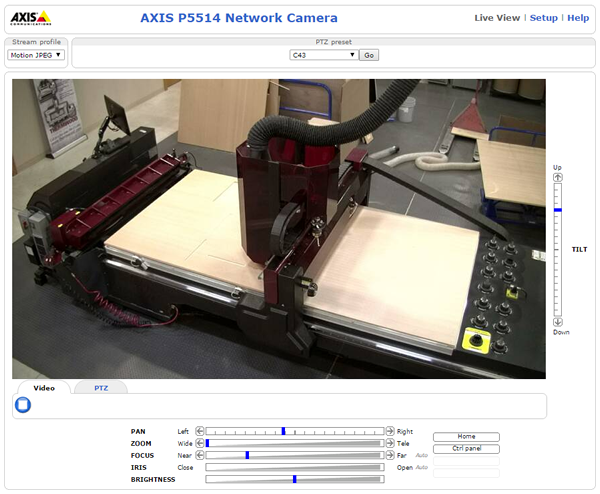

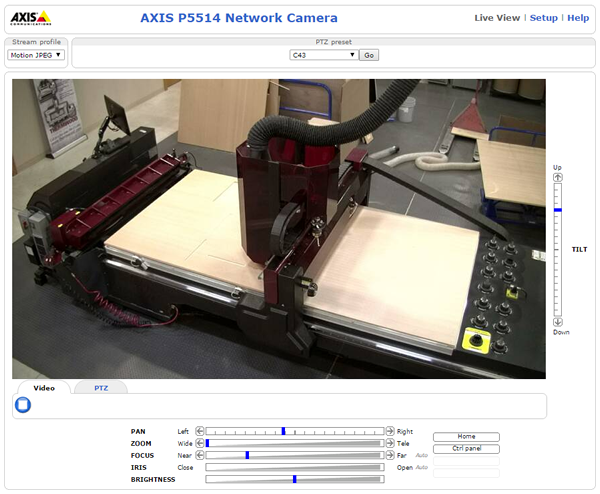

View Your Thermwood CNC Router Through Your WebCam

This is a convenient way to watch your machine remotely.

How it Works

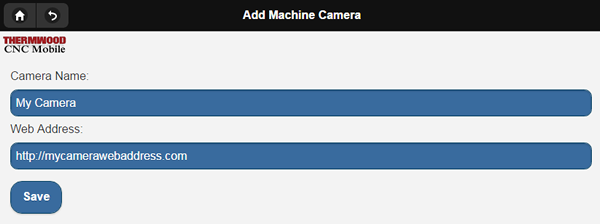

You set up your own web cam (must be an SSL enabled camera for security), and host it on a web page you control. Then, inside the Thermwood app, you can enter in the address of your camera feed (on your hosted page), and access it through the app.

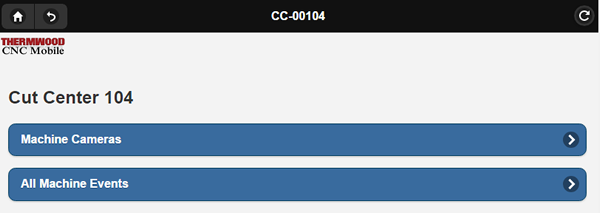

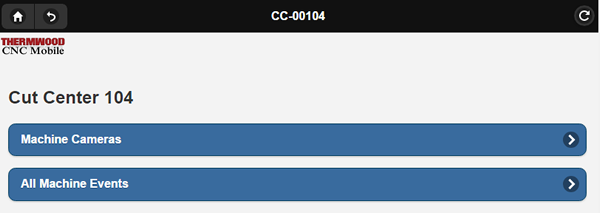

Click Machine Cameras to bring up a lising of all accessible cameras in the app

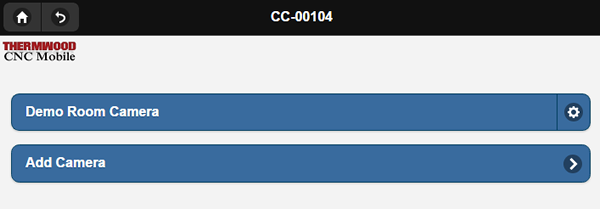

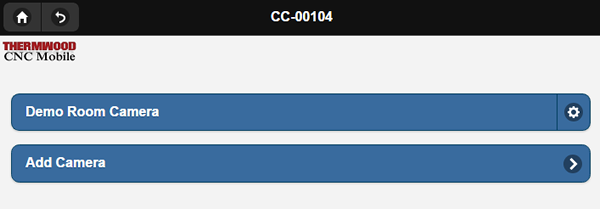

Listing of all added cameras and link to add additional cameras

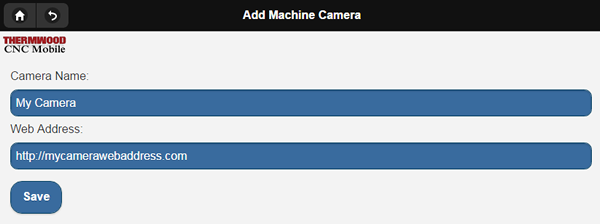

Add a new camera by entering in a name and web address to your hosted web cam

More Details

This feature is not designed to be used as a remote management or operation tool, only as an access point in the app that points to the host of your choice. It is only designed to be used as a viewer, not for remote operation of your machine.

Recommended Camera

Thermwood recommends the Axis M5525-E PTZ Camera, but any SSL enabled camera that you can host on your site should work. Note: Thermwood will not be able to provide technical support on your camera or hosting platform, only on our app.

Get The Thermwood Mobile App

Also available on any browser here: https://server.thermwood.com/thmmobileapp

|

|

|

Please click the "Request a Consultation" link above or give us a call at 1-800-533-6901 and we will sit down and show you how all this happens, in detail.

|

Smart-routers live on the web. They access updates on the web, are serviced through the web and let you monitor and manage your smart-router using your smart phone or tablet.

Smart-routers live on the web. They access updates on the web, are serviced through the web and let you monitor and manage your smart-router using your smart phone or tablet. A listing of the cycle time of every part program ran in chronological order

A listing of the cycle time of every part program ran in chronological order

Smart-routers

Smart-routers

The

The

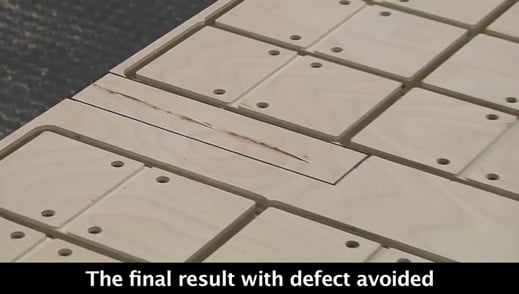

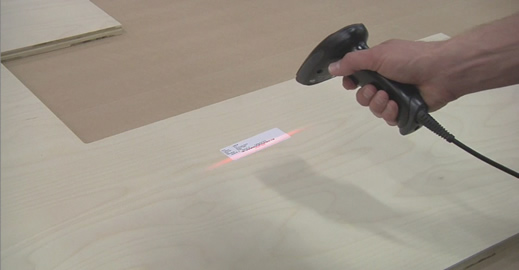

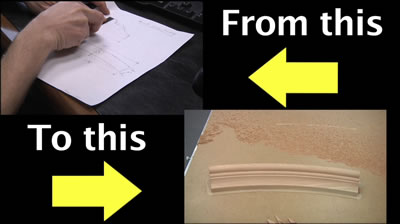

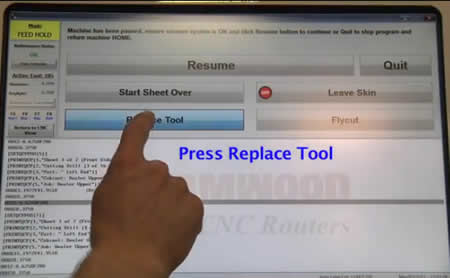

Replacing bad or scrap parts is really easy with a

Replacing bad or scrap parts is really easy with a

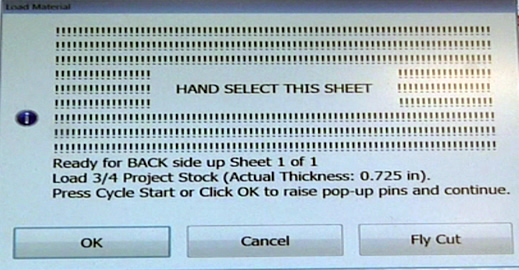

Smart-routers give you more

Smart-routers give you more Smart-routers alert you when running critical or prominent parts. Certain parts are prominent on the final product, door and drawer fronts for example.

Smart-routers alert you when running critical or prominent parts. Certain parts are prominent on the final product, door and drawer fronts for example.