Experts say so at industry seminars, however, major aerospace companies 3D print molds every day that don’t have void or porosity problems. How can this be?

Watch the 8 minute video below and learn the simple answer.

Posted by Duane Marrett on Wed, Sep 29, 2021

Experts say so at industry seminars, however, major aerospace companies 3D print molds every day that don’t have void or porosity problems. How can this be?

Watch the 8 minute video below and learn the simple answer.

Posted by Duane Marrett on Mon, Sep 20, 2021

Tags: Thermwood, Announcements, Race Car, Sponsor, SCCA

Dale, Indiana based Thermwood Corporation will enter into an LSAM/Thermwood sponsorship arrangement with Columbus, Ohio based Alliance Autosport for one of Thermwood’s own employees. The employee will be racing in the Sports Car Club of America (SCCA) “Runoffs” at the famed Indianapolis Motor Speedway during the last week of September and into October.

The Runoffs is the SCCA’s annual winner-take-all national championship. The competition brings together the best qualified amateur racers from all over the US and Canada to compete across 26 different race car classes for the 58th consecutive year.

The young driver, Gabe Fehribach, is a member of Thermwood’s engineering team. Gabe fulfilled his Runoffs qualification requirements earlier this year after racing at such storied venues as VIRginia International Raceway, Circuit of the Americas, Mid-Ohio Sports Car Course, and Watkins Glen International, among others.

Following three days of qualifying beginning September 28th, Gabe will compete with his winged, open-wheel SCCA Enterprises Formula Enterprises 2 race car the morning of Friday, October 1st against 28 other drivers all running the same spec chassis, Sunoco fuel, Hoosier tires, and Mazda power unit.

Tickets for the three days of racing beginning October 1st can be purchased through the Indianapolis Motor Speedway website.

For more information on Thermwood, the SCCA Runoffs, Alliance Autosport, and Indianapolis Motor Speedway, visit these websites:

http://www.thermwood.com

http://www.scca.com/runoffs

http://www.allianceautosport.com

http://www.indianapolismotorspeedway.com

Posted by Duane Marrett on Thu, Sep 02, 2021

Tags: Thermwood, Announcements, Trade Shows, Large Scale, Thermwood LSAM, SABIC, LSAM Additive Printers, RAPID + TCT, Airtech, High Temperature, Techmer PM

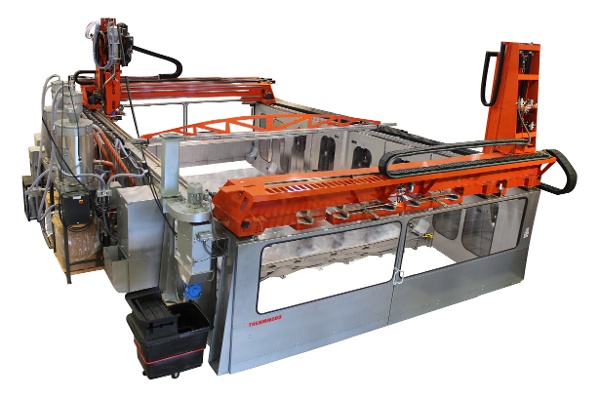

Thermwood will be printing high temp autoclave aerospace tooling on an LSAM Additive Printer 510 LIVE at RAPID + TCT 2021 in Chicago, IL September 13th-15th. LSAM Research Laboratory at Purdue ADDITIVE3D Software will be on display as well, with Purdue representatives on site for demonstrations. We will be printing a different material each day, donated by SABIC, TECHMER PM and AIRTECH. This promises to be an exciting demonstration of the LSAM Additive Printer Large Scale Additive System.

Click the link below to Be Our Guest and register for a Free Rapid + TCT Expo pass and $100 off the Conference Registration Fee.

Use Promo Code: 10016220

Make plans now to visit the McCormick Center and stop by Thermwood booth #E7628 to witness this live and in-person!

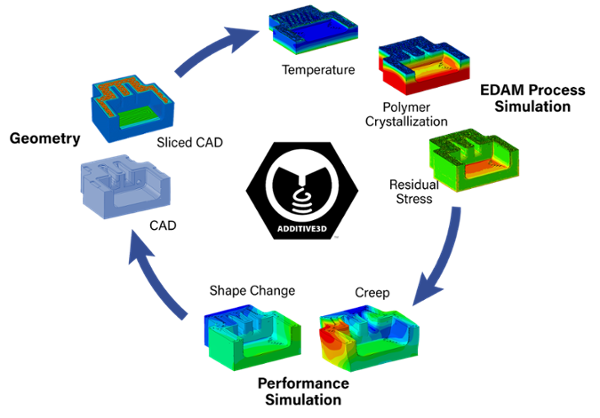

Representatives from the recently announced Thermwood Research Laboratory at Purdue University (located in Purdue University's Composites Manufacturing Simulation Center - CSMC) will also be on hand to demonstrate their ADDITVE3D simulation software.

On Monday, September 13th we will be printing SABIC LNP™ THERMOCOMP™ AM EC004XXAR1 ULTEM compound.

On Tuesday, September 14th, we will be printing TECHMERPM PESU 1810 3DP.

On Wednesday, September 15th, we will be printing AIRTECH PEI DALTRAM I-350CF

Posted by Duane Marrett on Thu, Aug 19, 2021

Tags: Thermwood, Announcements, Large Scale, Thermwood LSAM, Boeing, Book, Additive Manufacturing Guide

This 315 page book, currently available as either an eBook or paperback hardcopy, is intended to help non-technical managers understand the basics behind a new technology that is revolutionizing production of large composite molds, tools and other industrial and commercial products.

Where to Purchase

This book is currently available from Amazon either as an electronic file or as a printed hardcopy.

Who This Book is For

If you are a manager in an industrial company who might benefit from large scale additive technology, or, if your company is actively exploring this technology, this book will give you the background you need to participate and make better decisions. It will also help you cut through the confusion and crosstalk that often accompanies a new technology like this.

More InfoIndustrial additive manufacturing is currently being used successfully every day to produce some of the largest composite parts ever made. These include large aerospace molds and tools, foundry patterns for various industries, chassis for electric busses and what is likely the tallest 3D printed structure ever made. Although the process results in substantial savings and dramatically reduces lead time, much of industry today still doesn’t understand or trust it.

In this book, the author, who was instrumental in developing the technology actually being used in industry today, explains in everyday, no nonsense language what it is, how it works, what actually works, what doesn’t and why. He provides a guide for non-technical managers to help them understand the basics so they can evaluate how this new technology might impact their company.

He explores all aspects of this process in clear, easy to understand language including the print process, polymers, software, trimming, cost savings, time savings, computer simulation and the practical, real world, aspects of getting into large scale additive. He includes sometimes humorous vignettes about surprises, missteps and stumbles during initial technology development and how they were handled.

About the Author

The author, Ken Susnjara, is the founder, Chairman and CEO of Thermwood Corporation, the leading supplier of large scale additive systems for the production of thermoplastic composites. With almost 100 patents to his name, he was instrumental in the development of the underlying technology behind the most successful large scale additive systems today.

The author, Ken Susnjara, is the founder, Chairman and CEO of Thermwood Corporation, the leading supplier of large scale additive systems for the production of thermoplastic composites. With almost 100 patents to his name, he was instrumental in the development of the underlying technology behind the most successful large scale additive systems today.

Posted by Duane Marrett on Wed, Jun 30, 2021

Tags: Thermwood, Announcements, Large Scale, Thermwood LSAM, Navy, Composite Tooling, Boeing, Navair, Collaboration, Fleet Readiness Center

Thermwood was a key development partner in a Navy ManTech funded program issued to Boeing Research and Technology. The ManTech program was managed by Advanced Technology International (ATI) for the Office of Naval Research (ONR) with funding provided from the Naval Air Systems Command (NAVAIR) Aircraft Equipment Reliability & Maintainability Improvement Program (AERMIP). Fleet Readiness Center East (FRCE) was a key technical contributor for the low cost composite cure tooling technology development.

Thermwood’s Large Scale Additive Manufacturing (LSAM) machine was selected as the Large Format Additive Manufacturing (LFAM) machine to conduct the technology development. Several unique equipment features of the LSAM machine drove the selection. The high temperature autoclave cure tooling operating environment of 355 degree Fahrenheit and 85 psi provides a challenge for polymer based tool material. Additional composite cure tooling requirements for vacuum integrity and dimensional stability were validated during the development. Neil Graf Office of Naval Research, noted “Composite manufacturing is a strategic technology for future platforms and development of more cost effective tooling solutions would significantly benefit the implementation.”

FRCE provided a high contour mold line surface to Boeing for generating the composite cure tool. The mold line shape was very aggressive and would stretch the large format additive manufacturing technology processes capability. The spherically shaped portion of the mold line offered the largest challenge, as the unsupported 3D printed angle limitation of approximately 45 degrees provides an interesting obstacle to overcome for the spherical mold line section of the tool. Boeing rotated the 3D print plane 35 degrees to avoid encroachment of the build angle limitation.

The new innovative build plane approach eliminated the requirement for temporary support material for the aggressive mold line shape. The new build angle would test the LSAM machine limits in an area never explored previously. TechmerPM PESU CF 1810 high temperature print material was used for the composite cure tool. High temperature materials present additional challenges during print over low temperature materials such as ABS CF. Two interim support features were added to compensate for the center of gravity shift of the print. The LSAM machine performed flawlessly during the composite cure tool print. The tool was printed in 7 hours and 26 minutes using 610 lbs of material.

The composite cure tool was machined in 53 hours using the LSAM gantry router machine. The tool datum features, and removal of interim members, were machined prior to removal from the bead-board. The Thermwood LSAM machine offers the ability to machine and 3D print on a single platform. The composite cure tool mold line part surface achieved at surface profile tolerance of .020” (+/-.010”).

The Boeing Research and Technology (BR&T) laboratory performed functional testing on the LFAM composite cure tool to ensure vacuum integrity and dimensional stability requirements were reached. The LFAM tool performed as expected and achieved all requirements. Several composite parts were fabricated from the tool. The tool durability was assessed during the multiple autoclave cure cycles and fabricated (3) composite parts. The tool maintained dimensional stability and vacuum integrity throughout the functional testing and composite part manufacturing.

The composite cure tool was printed and NC machined on Thermwood’s Large Scale Additive Manufacturing (LSAM) 1020 machine. The LFAM technology cost savings was estimated at 50% compared to traditional tool fabrication methods, and reduced tool fabrication lead-time by 65%. The cost savings and tool fabrication cycle time reduction could provide enormous benefit to any organizations performing low volume or custom composite part fabrication and repair.

Nondestructive Inspection (NDI) was performed on the composite parts fabricated on LSAM tools. The NDI results did not indicate any porosity. Due to the complex shape of the composite demonstration part several NDI process were employed. X-ray and C-Scan results did not reveal any delaminations or defects.

The program benefited from a cooperative effort among several contributors to achieve success. The partnership between industrial technology leaders, Boeing and Thermwood coupled with the Office of Naval Research’s drive to transition technology, led to the successful program. “Collaborations such as this help expand the scope of capabilities of emerging large scale additive technology by addressing real world challenges that would be difficult for any single entity to define and address by itself. We look forward to new challenges moving forward”, says Thermwood CEO, Ken Susnjara.

Additional development is key to expand LFAM composite cure tooling implementation. Boeing Associate Technical Fellow Michael Matlack commented “The program provided significant results in validating additive manufacturing as a viable method of producing lower cost, capable tooling with substantial time savings over traditional methods.”

Posted by Duane Marrett on Fri, Jun 25, 2021

Tags: Thermwood, Announcements, Trade Shows, AWFS, Cut Center, CutReady, 2021, CabinetShop 43

For AWFS 2021, Thermwood Corporation, an innovator in the design and manufacture of 3 and 5 Axis CNC Routers, is proud to demonstrate two systems. We’ll have our versatile and affordable CabinetShop 43 510-8 and our powerful Cut Ready Cut Center machining on site.

Cabinetshop 43

We will be machining plastic sheets, signs, outdoor furniture and nested based applications on our CabinetShop 43 510-8 CNC Router. This machine features a 5'x10' base with a 5'x8' table, allowing it to offer 21 tooling positions with its automatic bar style tool changer. It also has an improved dual pipe dust collection system, programmable pop-up pins, auto tool length measurement and an automatic lubrication system. This configuration is also available as a 512-10, with a 10 foot table on a 12 foot base. Auto labeling and an unload rake system for nested based production are also available as an option.

.jpg?width=400&name=cut_center_cnc_router_image%20(1).jpg) Thermwood will also be demonstrating the award-winning Cut Ready Cut Center. This powerful system helps you quickly and easily create most products a cabinet shop would want to make without a CNC programmer (cabinets, furniture, doors, drawers, moldings, stair stringers and much more). Just tell it what you want to make via a simple touch-screen interface, and it makes it. Or, you can operate it as a traditional CNC router.

Thermwood will also be demonstrating the award-winning Cut Ready Cut Center. This powerful system helps you quickly and easily create most products a cabinet shop would want to make without a CNC programmer (cabinets, furniture, doors, drawers, moldings, stair stringers and much more). Just tell it what you want to make via a simple touch-screen interface, and it makes it. Or, you can operate it as a traditional CNC router.

Most people can operate it with little or no training or guidance. It is complete, fully contained with all the ancillary equipment smoothly integrated into a package that almost runs itself.

We'll be demonstrating live on both machines during the show, as well as operating an eCabinet Systems kiosk. Our eCabinet Systems expert will be designing nested-based applications on the fly to send to the CabinetShop 43 to be machined. In addition to our Cut Center live demonstrations, we will also have two Cut Ready kiosks, where you can explore the software and see just how easy it is to design most things a cabinet shop would want to make.

We'll be demonstrating live on both machines during the show, as well as operating an eCabinet Systems kiosk. Our eCabinet Systems expert will be designing nested-based applications on the fly to send to the CabinetShop 43 to be machined. In addition to our Cut Center live demonstrations, we will also have two Cut Ready kiosks, where you can explore the software and see just how easy it is to design most things a cabinet shop would want to make. Take a Tour of the Cut Ready Cut Center

Learn How Simple it is to Machine a Cabinet Job on the Cut Ready Cut Center

Exploring Cut Ready's Leveling Feature

Posted by Duane Marrett on Fri, Jun 18, 2021

Tags: Thermwood, Announcements, Scholarship, 2021

Thermwood is proud to announce that we will be awarding three scholarships to dependents of associates for the Class of 2021. Each recipient will receive a $2,000 renewable scholarship.

Since the introduction of these renewable scholarships, Thermwood has awarded over $200,000 to students wishing to further their education.

Leah O'Brien is the daughter of Jennifer and Chris O'Brien of Stendal, IN. She is a graduate of Southridge High School.

She has been involved in FCA, Natural Helpers, SHS Choir, Yearbook and St. Mary's Youth group. She was also a member of the Swim, Cross Country and Track teams.

Leah plans to attend Ivy Tech Community College in the fall to study Visual Communications.

Aiden Susnjara is the son of April and Jason Susnjara of Santa Claus, IN. He is a Summa Cum Laude graduate of Heritage Hills High School.

He has been a member of Beta Club as well as the Basketball, Tennis and Golf teams. Aiden has also been involved with Riley's Dance Marathon.

Aiden plans to attend Purdue University in the fall to study Engineering.

Kylee Vaal is the daughter of Courtney and Scott Vaal of Jasper, IN. She is a graduate of Jasper High School.

Kylee Vaal is the daughter of Courtney and Scott Vaal of Jasper, IN. She is a graduate of Jasper High School.

She has been involved in FCA, Octagon Club and SADD. She is also a volunteer for the Redemption Church Kids Ministry. Kylee was also part of the Soccer, Basketball and Unified Track teams.

Kylee plans to attend the University of Southern Indiana to study Biology.

Thermwood would like to congratulate all seniors of the Class of 2021 and wish them the very best in their future studies and endeavors!

Posted by Duane Marrett on Tue, Jun 08, 2021

Tags: Thermwood, software update, Announcements, Cut Ready, Cut Center, moldings, Cut Center Updates, Shapes, Publisher, Combination Cabinets, Options, Pre-Drill

Pre-drill your cabinets for a wide variety of slides, hinges, and hinge plates!

We have all the popular hardware patterns within Cut Ready including Blum, Accuride, Grass, Hafele, and Salice. Not only does this speed up production, it also increases the accuracy and placement of the hardware itself. Simply select your preferences within the Settings menu, or change it on-the-fly when processing a job.

If you haven’t decided on hardware yet, you can turn the patterns off, or use Cut Ready’s Universal Patterns and get to cutting.

Select your manufacturer and options...

Customize the pattern defaults on your slides and hinges...

Posted by Duane Marrett on Tue, May 11, 2021

Tags: Thermwood, Announcements, Thermwood LSAM, Why LSAM

Companies have been choosing Thermwood’s LSAM large scale additive manufacturing systems for their thermoplastic composite large part production. In a newly released video, Scott Vaal, Thermwood’s LSAM Product Manager, addresses the question of "Why LSAM?"

He addresses key aspects of the large scale additive manufacturing market and LSAM’s position in it. This video also addresses the current state of the art in additive print technology, offers a quick overview of the broad LSAM product line, slicing software, industry collaboration, additive system reliability, service, support, upgrade ability, plus other issues important to potential users and anyone interested in large scale additive manufacturing of thermoplastic composites.

Thermwood has found that many companies exploring large scale additive manufacturing don’t have a clear understanding of the current state of the market, the available technology or the capabilities of systems currently available. This video is intended to add a level of understanding, comfort and confidence that capable, proven and reliable large scale additive systems are not only available, but are already successfully operating in major industries every day, generating significant benefits and profits.

Largest Selection of Large Scale Additive Manufacturing Systems

With the introduction of the smaller LSAM Additive Printers plus these new wide table flagship LSAMs, Thermwood’s large scale additive manufacturing product line is, by far, the broadest available anywhere, with LSAM models from 5x5 foot to these new fifteen foot wide flagship models.

Posted by Duane Marrett on Tue, Apr 20, 2021

Tags: Thermwood, Announcements, Thermwood LSAM

Thermwood Corporation, manufacturer of the highly successful LSAM large scale thermoplastic composite additive systems, has announced the availability of even larger size machines than we currently offer.

The LSAM additive manufacturing system line is already the broadest in the industry with additive printers from a 5x5 foot table to large dual gantry print and trim systems up to 10x40 foot. Machines longer than 40 foot are available, but several 10x40 systems are the largest built to date.

With this new announcement, the large dual gantry print and trim machines are now available in a 15 foot width in addition to the current 10 foot width tables. As with the ten foot wide tables, the new fifteen foot wide table machines are available in lengths from twenty foot on, in ten foot increments.

New Heavier Gantry Design

The new machines utilize the new wide gantry design that was first developed for Thermwood’s LSAM 1010. The LSAM 1010 has both a print head and a trim head mounted on the same gantry, hence the need for a wide gantry even though the table is only 10x10 foot. The dual head combination on the 1010 weighs over 7,000 pounds, requiring a significant engineered gantry structure.

The smallest table length available in the fifteen foot width LSAM is twenty foot, however, because of the modular design of the table and support walls, this length can be increased by ten foot increments. The most popular table lengths to date for the ten foot wide table LSAM machines have been twenty foot and forty foot.

40mm or 60mm Print Core Available

The new machines are equipped with the large LSAM print head structure which can be equipped with either the 40mm or 60mm print core. The 40mm core can print most polymers at about 200 pounds per hour while the 60mm core can print at over 500 pounds per hour. They can also be equipped with Thermwood’s patented Vertical Layer Print system, which makes it technically possible to print parts up to fifteen foot wide and as tall as the length of the table.

Same Powerful Features

The new machines are equipped with all the advanced features of the entire LSAM line including the thermal sensor layer automation system which automatically controls bead temperature at layer fusion producing virtually perfect bonding between layers.

As the market becomes more comfortable with the capability and reliability of LSAM technology, the new sizes open interesting opportunities in areas where really, really large parts are needed.

Three Print Head Options Available

Thermwood offers three print head options on various machines with maximum print rates of 100, 200 and over 500 pounds per hour. Although many believe that print rate determines how fast a layer can be printed, it is actually polymer cooling that determines how much time is needed between layers.

Print head output then determines how much bead can be printed in that time and thus how large a part that can be printed by that print head using that polymer. The Thermwood LSAM 60mm print head with 500 pound per hour maximum print rate can print the largest part layers possible today.

Largest Selection of Large Scale Additive Manufacturing Systems

With the introduction of the smaller LSAM Additive Printers plus these new wide table flagship LSAMs, Thermwood’s large scale additive manufacturing product line is, by far, the broadest available anywhere, with LSAM models from 5x5 foot to these new fifteen foot wide flagship models.

© Thermwood Corporation. All Rights Reserved