Thermwood PH50 Head Successfully Tested

After recently announcing our line of LSAM (large scale additive manufacturing) machines, Thermwood has now built and tested a high output version of our PH Series composite thermoplastic 3D print head.

After recently announcing our line of LSAM (large scale additive manufacturing) machines, Thermwood has now built and tested a high output version of our PH Series composite thermoplastic 3D print head.

At a print rate of 500 lbs/Hr, our newest and largest print head, the PH50 is more than three times faster than even our current PH15 print head (which we believe is currently the highest output composite thermoplastic print head available).

The Thermwood-designed PH series print head uses three servo drives in a unique configuration.

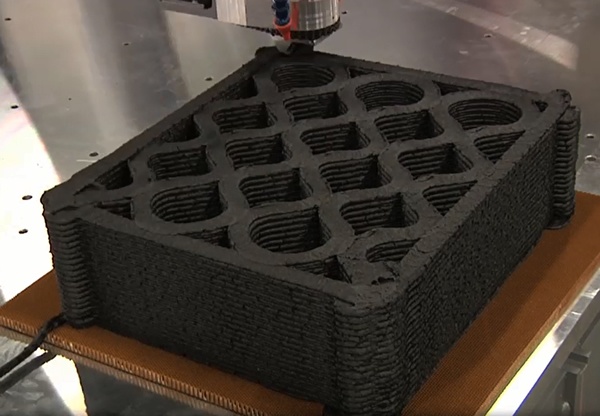

The advantages of this new design include:

- a highly accurate print bead, the ability to change bead size while printing

- high output print rates

- better fusion between printed layers

- a virtually void-free printed structure

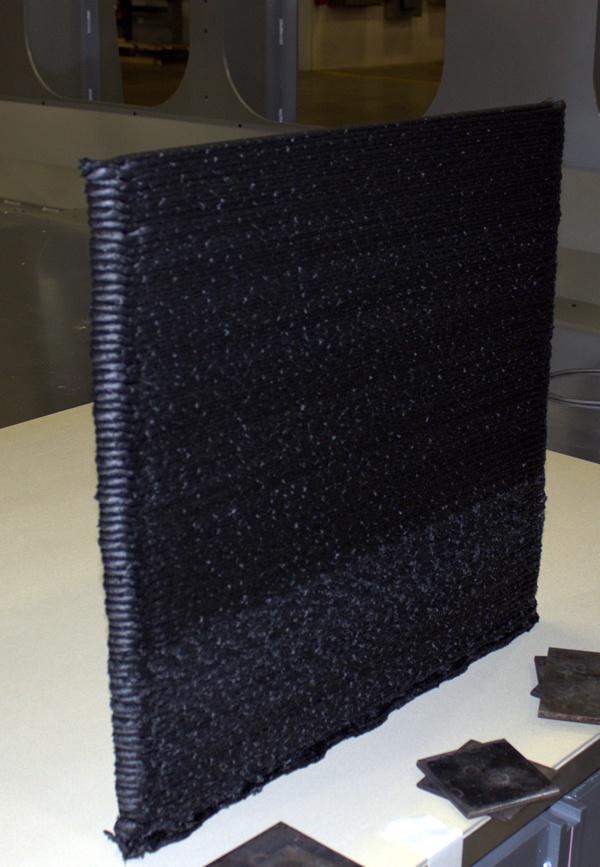

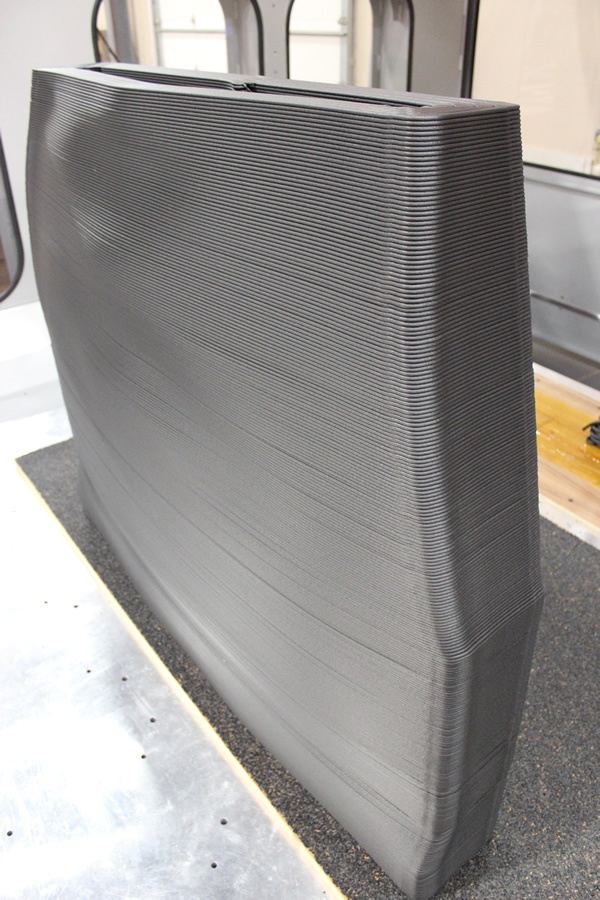

Thermwood has been operating the PH15 print head on the development version of our large scale additive manufacturing machine, called LSAM (L-Sam). The PH15 features a maximum print output rate of 150 Lbs/Hr when running a 20% carbon fiber filled ABS material. Our newest, and largest print head, the PH50, has been successfully bench-tested at a print rate of slightly over 500 Lbs/Hr running the same material.

A New Way to 3D Print

Fast print rates make possible all new ways to 3D print. The maximum print rate on a particular part is dictated not by the output of the print head, but instead, by cooling. When a layer is printed it must be allowed to cool sufficiently to stiffen enough to support the next layer but should not be allowed to cool so much that it doesn’t fuse properly with the next layer. This means that, although you may be able to print much faster, with most materials, you must wait at least 1 ½ to 2 minutes before you can print another layer. This would tend to make high output print heads unnecessary except for really large parts, but there are situations where this is not the case.

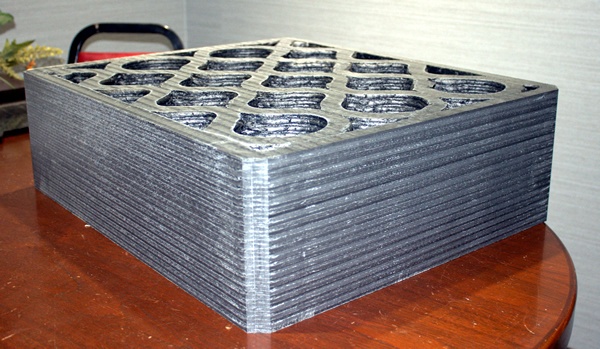

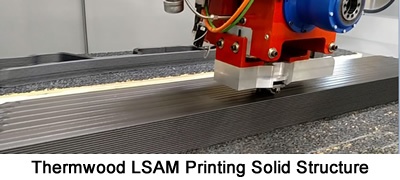

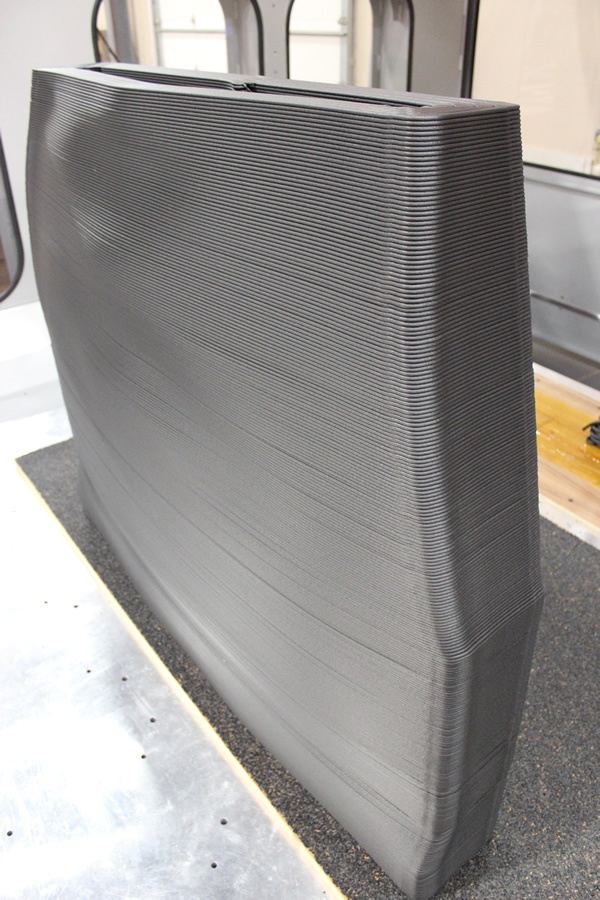

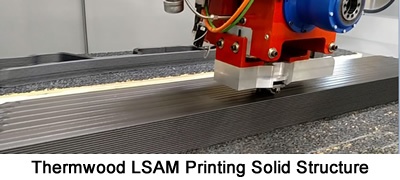

At times, parts are printed as completely solid structures. When this occurs, bead length adds up quickly. A 5 foot by 5 foot solid layer requires 375 feet of bead length with a 0.800” bead width. Even with a 125 foot per minute print speed (which is the print speed of the PH50 at full output), it will require at least three minutes to print that layer. While this is still within a good layer to layer working time, it is clearly not overly fast.

At times, parts are printed as completely solid structures. When this occurs, bead length adds up quickly. A 5 foot by 5 foot solid layer requires 375 feet of bead length with a 0.800” bead width. Even with a 125 foot per minute print speed (which is the print speed of the PH50 at full output), it will require at least three minutes to print that layer. While this is still within a good layer to layer working time, it is clearly not overly fast.

Some parts which are printed vertically are so long that they must be printed in multiple sections which are then bonded together. With a fast enough print head and large enough table, all sections can be printed at one time rather than printing them one at a time. In this approach, you print a layer on one part, then move to the next and the next, until you have printed that layer on all the parts. Then, you return to the first part which should then be ready for another layer. You can also mix different types of parts and print them all at the same time, rather than one at a time. With additive manufacturing technology today, this is the only way to speed up production rate. This approach makes fast print heads and large table sizes not only practical but quite desirable.

Thermwood's PH Series Print Head Design

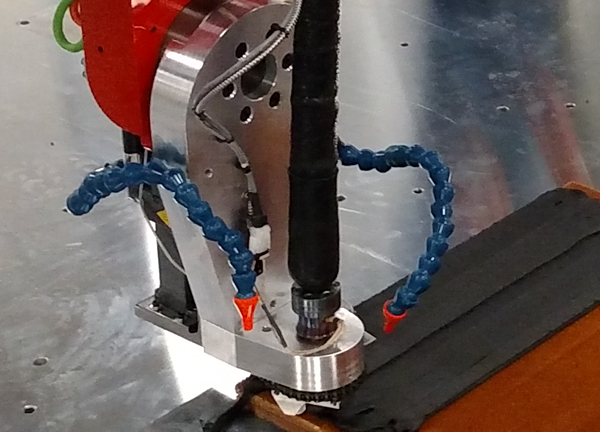

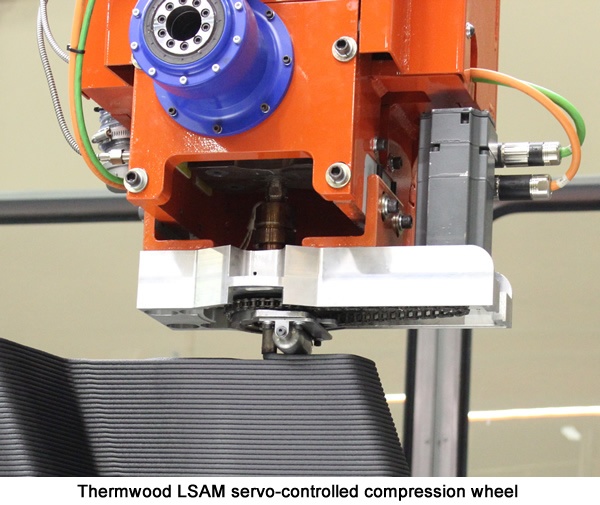

Thermwood’s PH Series print head design uses a servo-controlled plastic extruder with a specially designed, patented plasticating screw to heat and soften the composite thermoplastic material. It then uses a servo-controlled fixed displacement polymer pump to deliver the softened material at a precisely controlled rate to the print nozzle. This dual-servo, two-step approach to generating the print bead eliminates a variety of problems encountered when trying to use just an extruder to print and generates a highly controlled material flow rate which results in a highly accurate and controllable print bead size.

Thermwood’s PH Series print head design uses a servo-controlled plastic extruder with a specially designed, patented plasticating screw to heat and soften the composite thermoplastic material. It then uses a servo-controlled fixed displacement polymer pump to deliver the softened material at a precisely controlled rate to the print nozzle. This dual-servo, two-step approach to generating the print bead eliminates a variety of problems encountered when trying to use just an extruder to print and generates a highly controlled material flow rate which results in a highly accurate and controllable print bead size.

Thermwood’s PH Series system generates a relatively large print bead, applied at high speed. The print head is slaved to machine speed so as the machine speeds up and slows down, the output of the print head automatically adjusts to keep the size of the print bead consistent and accurate. This print speed control is automatic and doesn’t need to be incorporated into the CNC print program, greatly simplifying programming. An additional feature of this approach is that the print program can vary the size of the print bead during printing, something Thermwood has found to be a valuable capability.

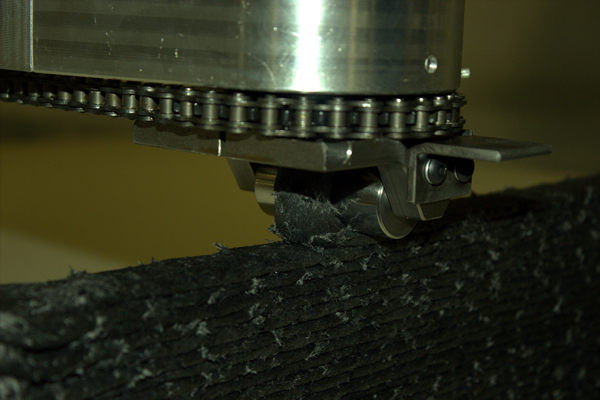

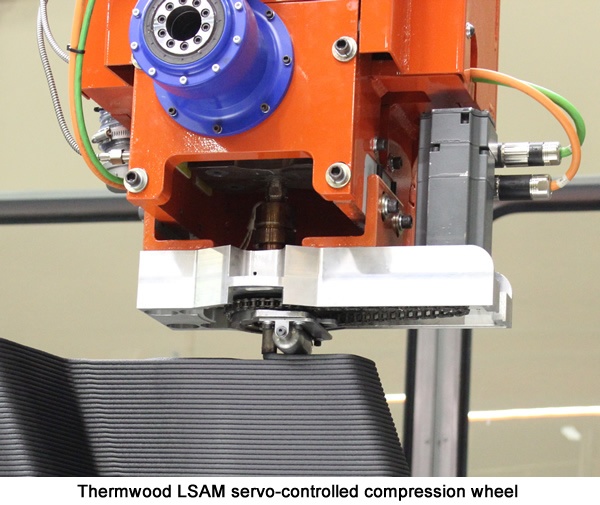

Once the bead has been applied, the PH Series print head uses a unique servo-controlled compression wheel to flatten and fuse each new print layer to previous layers. This wheel is the third servo in the PH series print head and can be instructed to automatically track machine motion.

Since it tends to squeeze out any air that might otherwise be trapped between layers during printing, Thermwood has found that this compression wheel results in superior bonding between printed layers and a virtually void free printed structure.

Another Unique Feature

A unique aspect of this new print head design is that, unlike machine motion, the three servo drives in the print head are not machine axes. Thermwood’s print gantries have six servo drive systems, but only three of them are axes. A machine axis needs to be programmed. The servo drives in the print head have their own unique, independent, self-operating intelligent control functions, which they continuously perform without specific ongoing CNC program commands.

The CNC program simply tells them to perform their function and they do it without further specific instructions, even if those functions require them to interact with the machine program, machine motion or each other. For example, simply turn on the print function and move the machine and the print head will print the proper size bead as the machine moves, automatically adjusting for acceleration, deceleration and different machine speeds. Engage the compression wheel and it follows machine motion automatically. During printing, a delicate balance exists between the extruder and polymer pump in the print head. Achieving and maintaining this balance during all aspects of operation is also automatic.

PH50 Successfully Operated at Full Output

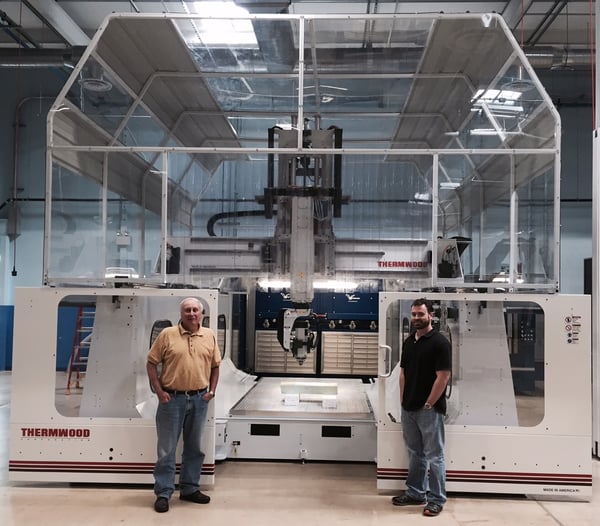

Currently, the new PH50 print head has successfully operated at full output in a static position. Thermwood is replacing its 10x10 foot LSAM development machine with a 10'x20' foot demonstration machine to verify and demonstrate operation of this new head at full print speed. Thermwood believes that 10'x20' is as small a machine as is practical for this high output print head. LSAM machines are available with table lengths of up to 100 foot or more. Thermwood is confident that technology in the PH Series print heads could be used in even higher output print heads should a need ever develop.

Currently, the new PH50 print head has successfully operated at full output in a static position. Thermwood is replacing its 10x10 foot LSAM development machine with a 10'x20' foot demonstration machine to verify and demonstrate operation of this new head at full print speed. Thermwood believes that 10'x20' is as small a machine as is practical for this high output print head. LSAM machines are available with table lengths of up to 100 foot or more. Thermwood is confident that technology in the PH Series print heads could be used in even higher output print heads should a need ever develop.

For More Information

The Thermwood line of LSAM machines are available now, and you can get more information and see videos of these new heads in operation here

We are constantly adding new features and abilities to the Award-Winning

We are constantly adding new features and abilities to the Award-Winning

Please come and visit us at CNC Automation booth #2013.

Please come and visit us at CNC Automation booth #2013.

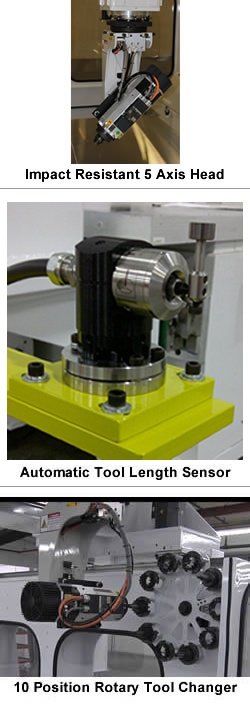

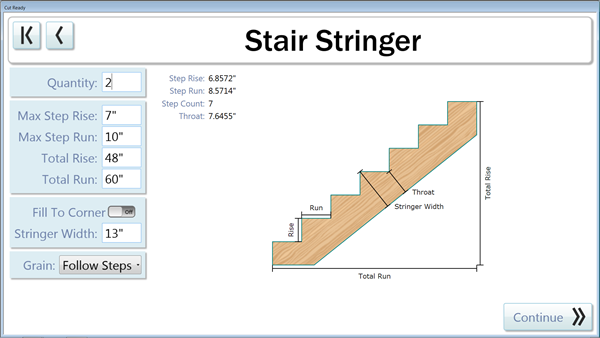

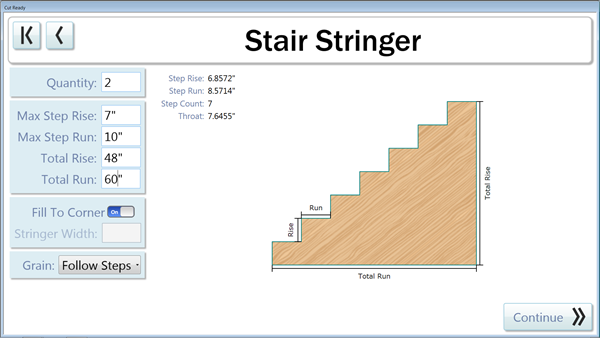

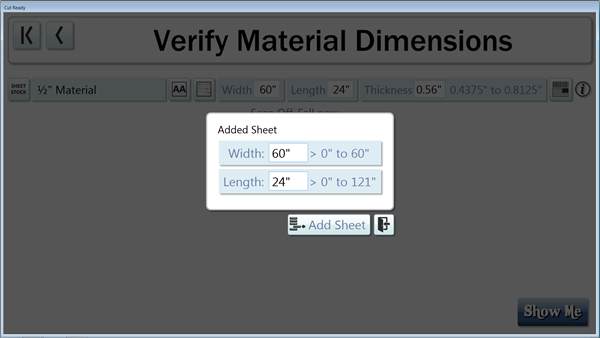

The AutoProcessor 5'x10' is a high-speed, automatic load/unload, heavy-duty CNC routing system for nested based feed through machining. It is used in nested based production of cabinets, closets and custom furniture.

The AutoProcessor 5'x10' is a high-speed, automatic load/unload, heavy-duty CNC routing system for nested based feed through machining. It is used in nested based production of cabinets, closets and custom furniture.