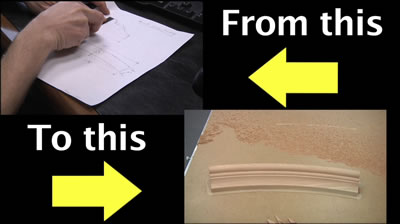

Smart-routers can machine a profile edge without a profile tool, by tracing over the edge multiple times with standard tools. It even works on curved moldings.

Smart-routers can machine a profile edge without a profile tool, by tracing over the edge multiple times with standard tools. It even works on curved moldings.

This saves a lot for any shop that makes custom moldings by allowing you to use Profile Modeler to quickly create a molding or custom shape from a sketch or drawing with no special shaped tooling required.

Overview: Smart-routers machine a profile edge without a profile tool

In depth: Profile Modeler - from Sketch to Production

Thermwood at AWFS 2013

Thermwood will be demonstrating many of the features of smart-router technology and nested based manufacturing at the 2013 AWFS show on July 24th-27th (Booth #8400). Plan to stop by and check it out, or click the button below to request a personal consultation on how we can help improve your production process.

|

Please click the "Request a Consultation" link above or give us a call at 1-800-533-6901 and we will sit down and show you how all this happens, in detail. |

Smart-routers give you more

Smart-routers give you more AWFS 2013 (July 24th-27th) promises to be an exciting time to visit Las Vegas. This year, Thermwood is proud to demonstrate our affordable

AWFS 2013 (July 24th-27th) promises to be an exciting time to visit Las Vegas. This year, Thermwood is proud to demonstrate our affordable  Sign up below to schedule a time during the show to meet with one of our CNC Experts (Booth #8400). They will evaluate your production needs to determine how you can best reduce costs and increase efficiency. Plus, receive a FREE 2 GB Flash Drive during your meeting!

Sign up below to schedule a time during the show to meet with one of our CNC Experts (Booth #8400). They will evaluate your production needs to determine how you can best reduce costs and increase efficiency. Plus, receive a FREE 2 GB Flash Drive during your meeting!

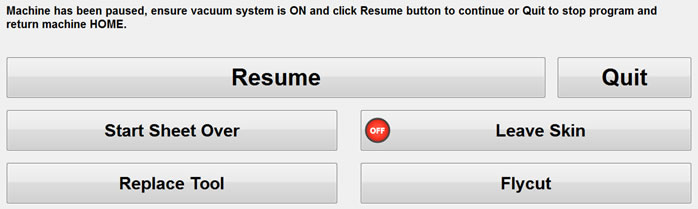

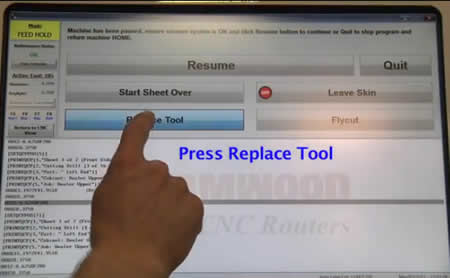

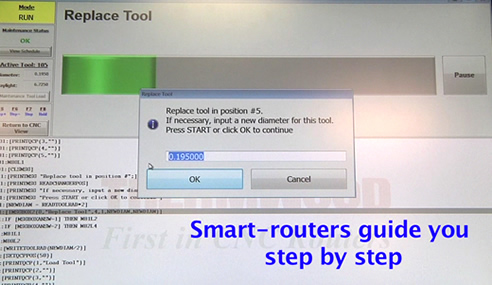

During program operation, smart-routers tell you what they are doing and offer instructions every step of the way. They tell you how many steps are in the program,what step they are on and what step is coming up next.

During program operation, smart-routers tell you what they are doing and offer instructions every step of the way. They tell you how many steps are in the program,what step they are on and what step is coming up next.